Abstract

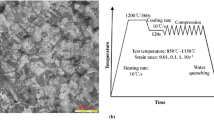

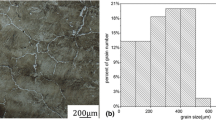

The dynamic recrystallization behavior of high strength steel during hot deformation was investigated. The hot compression test was conducted in the temperature range of 950-1150 °C under strain rates of 0.1, 1 and 5 s-1. It is observed that dynamic recrystallization (DRX) is the main flow softening mechanism and the flow stress increases with decreasing temperature and increasing strain rate. The relationship between material constants (Q, n, α and lnA) and strain is identified by the sixth order polynomial fit. The constitutive model is developed to predict the flow stress of the material incorporating the strain softening effect and verified. Moreover, the critical characteristics of DRX are extracted from the stress-strain curves under different deformation conditions by linear regression. The dynamic recrystallization volume fraction decreases with increasing strain rate at a constant temperature or decreasing deformation temperature under a constant strain rate. The kinetics of DRX increases with increasing deformation temperature or strain rate.

Similar content being viewed by others

References

WU Lai-zhi, LI Xue-song, CHEN Jun, ZHANG Hong-bing, CUI Zhen-shan. Dynamic recrystallization behavior and microstructural evolution in SPHC steel [J]. Journal of Shanghai Jiaotong University (Science), 2010, 15(3): 301–306.

MIRZADEH H, NAJAFIZADEH A. Prediction of the critical conditions for initiation of dynamic recrystallization [J]. Materials and Design, 2010, 31(3): 1174–1179.

MANDAL S, BHADURI A K, SARMA V S. A study on microstructural evolution and dynamic recrystallization during isothermal deformation of a Ti-modified austenitic stainless steel [J]. Metallurgical and Materials Transactions A, 2011, 42(4): 1062–1072.

BANDYOPADHYAY P S, KUNDU S, GHOSH S K, CHATTERJEE S. Structure and properties of a low-carbon microalloyed ultra-high- strength steel [J]. Metallurgical and Materials Transactions A, 2011, 42(4): 1051–1061.

SHUKLA R, DAS S K, RAVIKUMAR B, GHOSH S K, KUNDU S, CHATTERJEE S. An ultra-low carbon, thermomechanically controlled processed microalloyed steel: Microstructure and mechanical properties [J]. Metallurgical and Materials Transactions A, 2012, 43(12): 4835–4845.

OPIELA M. Effect of thermomechanical processing on the microstructure and mechanical properties of Nb-Ti-V microalloyed steel [J]. Journal of Materials Engineering and Performance, 2014, 23(9): 3379–3388.

CHEN Bing-hua, YU Hao. Hot ductility behavior of V-N and V-Nb microalloyed steels [J]. International Journal of Minerals, Metallurgy and Materials, 2012, 19(6): 525–529.

RAJPUT S K, CHAUDHARI G P, NATH S K. Physical simulation of hot deformation of low-carbon Ti-Nb microalloyed steel and microstructural studies [J]. Journal of Materials Engineering and Performance, 2014, 23(8): 2930–2942.

MA Li-qiang, LIU Zhen-yu, JIAO Si-hai, YUAN Xiang-qian, WU Di. Dynamic recrystallization behaviour of Nb-Ti microalloyed steels [J]. Journal of Wuhan University of Technology-Materials Science Edition, 2008, 23(4): 551–557.

SAIKALY W, CHARRIN L, CHARAÏ A, BANO X, ISSARTEL C. The effects of thermomechanical processing on the precipitation in an industrial dual-phase steel microalloyed with titanium [J]. Metallurgical and Materials Transactions A, 2001, 32(8): 1939–1947.

NIU Tao, KANG Yong-lin, GU Hong-wei, YIN Yu-qun, QIAO Ming-liang, JIANG Jin-xing. Effect of Nb on the dynamic recrystallization behavior of high-grade pipeline steels [J]. International Journal of Minerals, Metallurgy, and Materials, 2010, 17(6): 742–747.

GARCÍA-MATEO C, LÓPEZ B, RODRIGUEZ-IBABE J M. Effect of deformation temperature on microstructure and mechanical behaviour of warm working vanadium microalloyed steels [J]. Journal of Materials Science, 2011, 46(11): 3725–3737.

ZENG Y, WANG W. Computer simulation of carbonitride precipitation during deformation in Nb-Ti microalloyed steels [J]. Journal of Materials Science, 2008, 43(3): 874–882.

ARAB N B M, AYAZ M, KHAKI D M. Statistical modeling of strain-hardening exponent and grain size of Nb-microalloyed steels using a two-level factorial design of experiment [J]. Journal of Materials Engineering and Performance, 2013, 22(11): 3337–3347.

FERDOWSI M R G, NAKHAIE D, BENHANGI P H, EBRAHIMI G R. Modeling the high temperature flow behavior and dynamic recrystallization kinetics of a medium carbon microalloyed steel [J]. Journal of Materials Engineering and Performance, 2014, 23(3): 1077–1087.

CABRERA J M, OMAR A A, PRADO J M, JONAS J J. Modeling the flow behavior of a medium carbon microalloyed steel under hot working conditions [J]. Metallurgical and Materials Transactions A, 1997, 28(11): 2233–2244.

MIRZADEH H, CABRERA J M, NAJAFIZADEH A. Modeling and prediction of hot deformation flow curves [J]. Metallurgical and Materials Transactions A, 2012, 43(1): 108–123.

HUANG Shi-quan, YI You-ping, LI Peng-chuan, HE Hai-lin. Simulation of dynamic recrystallization in 23Co13Ni11Cr3Mo steel using a modified cellular automaton [J]. Journal of Central South University, 2014, 21(2): 454–459.

YANG Zhi-qiang, LIU Yong, TIAN Bao-hong, ZHANG Yi. Model of critical strain for dynamic recrystallization in 10%TiC/Cu-Al2O3 composite [J]. Journal of Central South University, 2014, 21(11): 4059–4065.

GU Sen-dong, ZHANG Li-wen, RUAN Jin-hua, ZHOU Ping-zhen, ZHEN Yu. Constitutive modeling of dynamic recrystallization behavior and processing map of 38MnVS6 non-quenched steel [J]. Journal of Materials Engineering and Performance, 2014, 23(3): 1062–1068.

POLIAK E I, JONAS J J. Initiation of dynamic recrystallization in constant strain rate hot deformation [J]. ISIJ International, 2003, 43(5): 684–691.

WAHABI M E, CABRERA J M, PRADO J M. Hot working of two AISI 304 steels: A comparative study [J]. Materials Science and Engineering A, 2003, 343(1/2): 116–125.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51322405) supported by the National Natural Science Foundation of China; Project(CX2013B085) supported by Hunan Provincial Innovation Foundation for Postgraduate, China

Rights and permissions

About this article

Cite this article

Wu, Gl., Zhou, Cy. & Liu, Xb. Dynamic recrystallization behavior and kinetics of high strength steel. J. Cent. South Univ. 23, 1007–1014 (2016). https://doi.org/10.1007/s11771-016-3149-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-016-3149-2