Abstract

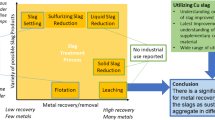

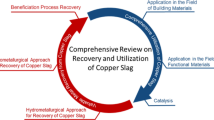

Determining the hydrometallurgical cut-off grades specifies the destination of low grade materials and this is subjected to more benefits in mining. Copper production rate is considered as one of the fundamental issues in hydrometallurgical cut-off grades determination. Slags are remarked as one of the main sources of copper. It is not only regarded as a waste but also identified as another resource extracting base metals. Slags are characterized by copper high grade. Thus, slag copper recovery can be led to different cut-off grades and net present value (NPV). The current research scrutinizes the effect of slag recovery by both flotation and hydrometallurgical methods on the hydrometallurgical cut-off grades. For this purpose, the optimum cut-off grade algorithms of hydrometallurgical methods are developed by considering associated environmental parameters, incomes and also the costs. Then, their optimum amounts are calculated with NPV maximization as an objective function. The results indicate that considering slag copper recovery in the hydrometallurgical cut-off grade algorithms reduces the environmental costs caused by slag dumping and leads to more NPV by 9%.

Similar content being viewed by others

References

LAVANYA C, SREERAMA RAO A, DARGA KUMAR N. A review on utilization of copper slag in geotechnical applications [C]// Proceedings of Indian Geotechnical Conference. New Delhi, India 2011: H–212.

PALACIOS J, SÁNCHEZ M. Wastes as resources: Update on recovery of valuable metals from copper slags [J]. Mineral Processing and Extractive Metallurgy 2011, 120(4): 218–223.

SCHLESINGER M, KING M, SOLE K C, DAVENPORT W G. Extractive metallurgy of copper [M]. Fifth edition. Oxford (UK): Elsevier Science Ltd. 2011: 88–89.

MURARI K, SIDDIQUE R, JAIN K. Use of waste copper slag, a sustainable material [J]. Journal of Material Cycles and Waste Management 2015, 17(1): 13–26.

MAKINEN J K, JAFS G A. Production of matte, white metal, and blister copper by flash furnace [J]. JOM 2013, 34(6): 54–59.

ROGÓZ K, KUCHARSKI M. The rate of metal oxygen reduction from the slag of the direct-to-blister flash smelting process [J]. Archives of Metallurgy and Materials 2010, 55(1): 317–323.

HUANG H, ZHU H, HU Y. Hydrophobic-surface of copper from converter slag in the flotation system [J]. International Journal of Mining Science and Technology 2013, 23(4): 613–617.

CARRANZA F, ROMERO R, MAZUELOS A, IGLESIAS N, FORCAT O. Biorecovery of copper from converter slags: Slags characterization and exploratory ferric leaching tests [J]. Hydrometallurgy 2009, 97: 39–45.

YANG Z, RUI-LIN M, WANG-DONG N, HUI W. Selective leaching of base metals from copper smelter slag [J]. Hydrometallurgy 2010, 103: 25–29.

CHEN M S H, HAN Z R, WANG L Z. Recovery of valuable metals from copper slag by hydrometallurgy [J]. Advanced Materials Research 2011, 402: 35–40.

NADIROV R K, SYZDYKOVA L, ZHUSSUPOVA A, USSERBAEV M. Recovery of value metals from copper smelter slag by ammonium chloride treatment [J]. International Journal of Mineral Processing 2013, 124: 145–149.

COURSOL P, VALENCIA N, MACKEY P, BELL S, DAVIS B. Minimization of copper losses in copper smelting slag during electric furnace treatment [J]. Journal of Mining, Material and Metallurgy 2012, 64(11): 1305–1313.

TSHIONGO N, MBAYA R K, MAWEJA K, TSHABALALA L. Effect of cooling rate on base metals recovery from copper matte smelting slags [J]. World Academy of Science, Engineering and Technology 2010, 70: 273–277.

SÁNCHEZ M, SUDBURY M. Physicochemical characterization of copper slag and alternatives of friendly environmental management [J]. Journal of Mining and Metallurgy B: Metallurgy 2013, 49(2): 161–168.

LANE K F. Choosing the optimum cut-off grades [J]. Colorado School Mines 1964, Q59: 485–492.

LANE K F. The economic definition of ore-cut-off grades in theory and practice [M]. California: Mining Journal Books Limited, 1988: 77–81.

BASCETIN A, NIETO A. Determination of optimal cut-off grade policy to optimize NPV using a new approach with optimization factor [J]. The Journal of the Southern African Institute of Mining and Metallurgy 2007, 107: 87–94.

DAGDELEN K, KAZUHIRO K. Cutoff grade optimization for large scale multi-mine, multi-process mining operations, mine planning and equipment selection [C]// International Symposium. Bangkok: Curran Associates 2007: 226–233.

ASAD M W A, TOPAL E. Net present value maximization model for optimum cut-off grade policy of open pit mining operations [J]. The Journal of the Southern African Institute of Mining and Metallurgy 2011, 111: 741–750.

DAVEY R. Mineral block evaluation criteria [M]// HUSTRULID W, KUCHTA M. Open pit mine planning and design. Roiterdam, Netherlands: SME-AIME, 1979: 83–96.

RENDU J M. An introduction to cutoff grade estimation [R]. The Society for Mining, Metallurgy and Exploration Inc. 2008.

RENDU J M. Cut-off grade estimation–old principles revisited–application to optimisation of net present value and internal rate of return [R]. Orebody Modelling and Strategic Mine Planning. Perth, 2009: 165–169.

WHITTLE J, WHARTON C. Optimizing cut-off grades [J]. Mining Magazine 1995, 1(1): 287–289.

ASAD M, DIMITRAKOPOULOS R. A heuristic approach to stochastic cutoff grade optimization for open pit mining complexes with multiple processing streams [J]. Resources Policy 2013, 38(4): 591–597.

RAHIMI E, ORAEE K, SHAFAHI Z, GHASEMZADEH H. Determining the optimum cut-off grades in sulfide copper deposits [J]. Archives of Mining Scince 2014, 60(1): 313–328.

OSANLOO M, RASHIDINEJAD F, REZ AI B. Incorporating environmental issues into optimum cut-off grades modeling at porphyry copper deposits [J]. Resources Policy 2008, 33(4): 222–229.

RAHIMI E, GHASEMZADEH H. A new algorithm to determine optimum cut-off grades considering technical, economical, environmental and social aspects [J]. Resource Policy, Doi:10.1016/j.resourpol.2015.06.004.

KING B M. Impact of rehabilitation and closure costs on production rate and cutoff grade [C]// International Symposium. London: United Kingdom Royal School of Mines, APCOM: 8-9.

RODRIGUEZ R, ROZGONYI T G. Evaluating the impact of environmental considerations in open pit mine design and planning [C]// International Symposium on Environmental Issues and Waste Management in Energy and Mineral Production. Antalya, Turkey: SWEMP 2004: 125–131.

RASHIDINEJAD F, OSANLOO M, REZ AI B. Cutoff grades optimization with environmental management; A case study: Sungun copper project [J]. IUST International Journal of Engineering Science 2008, 19: 1–13.

RAHIMI E, ORAEE K, SHAFAHI Z, GHASEMZADEH H. Considering environmental costs of copper production in cut-off grades optimization [J]. Arab Journal of Geoscince, Doi: 10.1007/s12517-014-1646-x.

GUPTA CH K. Chemical metallurgy: Principles and practice [M]. Mumbai: Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. 2006: 33–36, 112-116.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akbari, A., Rahimi, E. Effect of copper slag recovery on hydrometallurgical cut-off grades considering environmental aspects. J. Cent. South Univ. 23, 798–807 (2016). https://doi.org/10.1007/s11771-016-3126-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-016-3126-9