Abstract

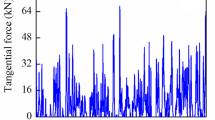

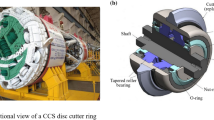

The center cutter of a hard rock tunnel boring machine (TBM) is installed on the cutterhead at a small radius and thus bears complex side force. Given this fact, the formation mechanism and change law of the side force suffered by the center cutter were studied. Based on the rock shear failure criterion in combination with the lateral rolling width, a model for predicting the average side force was set up. Besides, a numerical analysis model of the rock fragmentation of the center cutter was established, and the instantaneous load changing features were investigated. Results shows that the inner side of the center cutter can form lateral rolling annulus in rock during the rotary cutting process. The smaller the installation radius is, the greater the cutter side force will be. In a working condition, the side force of the innermost center cutter is 11.66 kN, while it decreases sharply when installation radius increases. Variation tends to be gentle when installation radius is larger than 500 mm, and the side force of the outermost center cutter is reduced to 0.74 kN.

Similar content being viewed by others

References

ROBY J, SANDELL T, KOCAB J, LINDERBERGH L. The current state of disc cutter design and development directions [C]// Proceeding of 2008 North American Tunneling Conference. San Francisco, USA: SME C, 2008: 36–45.

SONG Ke-zhi, WANG Meng-shu. Analysis of the operation characteristics of tunnel boring machine in complex rocks [J]. China Civil Engineering Journal, 2012, 45(5): 176–181. (in Chinese)

LIU H Y, KOU S Q, LINDQVIST P A, TANG C A. Numerical modeling of the heterogeneous rock fracture process using various test techniques [J]. Rock Mechanics and Rock Engineering, 2007, 40(2): 107–144.

WANG S Y, SLOAN S W, LIU H Y, TANG C A. Numerical simulation of the rock fragmentation process induced by two drill bits subjected to static and dynamic (impact) loading [J]. Rock Mechanics and Rock Engineering, 2011, 44(3): 317–332.

TAN Qing, ZHANG Kui, XIA Yi-min, ZHANG Kui. Numerical study on mode of breaking rock by TBM cutter in two cutting orders [J]. Journal of Central South University: Science and Technology, 2012, 43(3): 940–946. (in Chinese)

BALCI C, TUMAC D. Investigation into the effects of different rocks on rock cuttability by a V-type disc cutter [J]. Tunnelling and Underground Space Technology, 2012, 30: 183–193.

JI Chang-ming, ZHANG Zhao-huang, YE Ding-hai. The influence of the disc cutter space on rock’s jump break coefficients [J]. Journal of Basic Science and Engineering, 2008, 16(2): 255–263. (in Chinese)

GERTSCH R, GERTSCH L, ROSTAMI J. Disc cutting tests in Colorado Red Granite: Implications for TBM performance prediction [J]. International Journal of Rock Mechanics&Mining Sciences, 2007, 44(2): 238–246.

MOON T, OH J. A study of optimal rock-cutting conditions for hard rock TBM using the discrete element method [J]. Rock Mechanics and Rock Engineering, 2012, 45(5): 837–849.

ROSTAMI J. Study of pressure distribution within the crushed zone in the contact area between rock and disc cutters [J]. International Journal of Rock Mechanics and Mining Sciences, 2013, 57: 172–186.

ROSTAMI J. Development of a force estimation model for rock fragmentation with disc cutters through theoretical modeling and physical measurement of crushed zone pressure [D]. Golden, USA: Colorado School of Mines, 1997.

XIA Yi-min, OUYANG Tao, CHEN Lei, LUO De-zhi, ZHANG Xin-ming. Study on the influencing factors of the disc cutter performance [J]. Journal of Basic Science and Engineering, 2012, 20(3): 500–507. (in Chinese)

XIA Yi-min, OUYANG Tao, ZHANG Xin-ming, LUO De-zhi. Mechanical model of breaking rock and force characteristic of disc cutter [J]. Journal of Central South University, 2012, 19: 1846–1852.

HUO Jun-zhou, YANG Jing, SUN Wei, LI Qing-yu. Simulation and optimization design of three-dimensional rotating cutting action of TBM cutter group with different modes [J]. Journal of Harbin Engineering University, 2014, 35(11): 1403–1408. (in Chinese)

CHIKAOSA T, SHUNICHIRO Y, KIMIKAZU T. A study on cutter wear and mechanical properlies of rocks in tunneling with a TBM [J]. Journal of the Society of Materials Science, 2006, 55(1): 29–36.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2013CB035401) supported by the National Basic Research Program of China; Project(51475478) supported by the National Natural Science Foundation of China; Project(2012AA041803) supported by the High-Tech Research and Development Program of China

Rights and permissions

About this article

Cite this article

Xia, Ym., Tian, Yc., Tan, Q. et al. Side force formation mechanism and change law of TBM center cutter. J. Cent. South Univ. 23, 1115–1122 (2016). https://doi.org/10.1007/s11771-016-0361-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-016-0361-z