Abstract

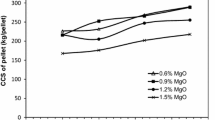

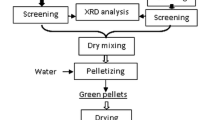

Pelletization of hematite ore requires high fineness and very high induration temperature (~1325 °C) owing to its poor diffusion bonding unlike magnetite ore. Further, high-alumina hematite pellets show very high reduction degradation index (RDI) during low temperature (500–650 °C) reduction due to their volume expansion and lattice distortion. Noamundi (India) hematite ore contains very high Al2O3 (2.3%) with adverse ratio of alumina to silica (~2) for which, it shows very high RDI. In this work, the acid pellets prepared from Noamundi ore fines of optimum Blaine fineness show good cold crushing strength (CCS). However, it shows very high RDI (77%). In order to reduce RDI, MgO in form of two different gangue-containing fluxes, such as pyroxenite and olivine in varying quantities has been added. The optimum requirement and performance of these fluxes has been examined and compared. Both pyroxenite and olivine fluxed pellets show significant lowering of RDI (26% and 23%, respectively) and improvement of other properties, viz CCS, swelling indices etc with good reducibility (70%–77%). Finally, a good quality acidic hematite pellet was developed from high-alumina ore without using any lime which is very important charge material in combination of basic sinter in blast furnace.

Similar content being viewed by others

References

DWARAPUDI S, GHOSH T K, SHANKAR A, TATHAVADKAR V, BHATTACHARJEE D, VENUGOPAL R. Effect of pyroxenite flux on the quality and microstructure of hematite pellets [J]. Int J Miner Processing, 2010, 96: 45–53.

PAL J, GHORAI S, AGARWAL NANDI S CHAKRABORTY B T, DAS G, PRAKASH S. Effect of blaine fineness on the quality of hematite iron ore pellets for blast furnace [J]. Mineral Processing and Extractive Metallurgy Review, 2015, 36(2): 83–91. DOI: 10.1080/08827508.2013.873862

SEMBERG P, ANDERSSON C, BJORKMAN B. Interactions between iron oxides and olivine in magnetite pellets during reduction to wustite at temperature of 1000–1300 °C [J]. ISIJ Int, 2013, 53(3): 391–398.

PAL J, ARUNKUMAR C, RAJSHEKHAR Y, DAS G, GOSWAMI M C, VENUGOPALAN T. Development on iron ore pelletization using calcined lime and MgO combined flux replacing limestone and bentonite [J]. ISIJ International, 2014, 54(10): 2169–2178.

GAO Qiang-jian, SHENG Feng-man, WEI Guo, JIANG Xin, ZHEN Hai-yan. Effects of MgO containing additive on low-temperature metallurgical properties of oxidized pellet [J]. Journal of Iron and Steel Research, International, 2013, 20(7): 25–28.

DWARAPUDI S, GHOSH T. K, TATHAVADKAR V, BHATTACHARJEE D, VENUGOPAL R, DENYS M B. Effect of MgO in the form of magnesite on the quality and microstructure of hematite pellets [J]. International Journal of Mineral Processing, 2012, 112-113: 55–62.

ZHU D, CHUN T, PAN J, ZHANG J. Influence of basicity and MgO content on metallurgical performances of Brazilian specularite pellets [J]. Int J Miner Process, 2013, 125: 51–60.

XU B, HOU T, CHEN X, LI Q, JIANG T, LI P. Effect of dolomite on reduction swelling property of iron ore pellets [J]. Journal of Central South University, 2013, 20: 2806–2810.

DWARAPUDI S, GHOSH T K, SHANKAR A, TATHAVADKAR V, BHATTACHARJEE D, VENUGOPAL R. Effect of pellet basicity and MgO content on the quality and microstructure of hematite pellets [J]. Int J Miner Process, 2011, 99: 43–53.

NARITA K, MAEKAWA M, SHIGAKI I. On the permeability resistance of pellets containing MgO in the softening and melting zone of blast furnace [J]. Trans ISIJ, 1977, 18: 712–720.

SIVRIKAYA O, AROL A I. Use of boron compound as binder in iron ore pelletization [J]. The Open Mineral Processing Journal, 2010, 3: 25–35.

BALL D F, DARTNELL J, DAVISION J, GRIEVE A, WILD R. Agglomeration of iron ores [M]. 1st ed. New York: Elsevier, 1973.

BOGDANDY L V, ENNGELL H J. The reduction of iron ore [M]. New York: Springer-Verlag, 1971: 34–35.

LU L, HOLMES R. J, MANUEL J R. Effect of alumina on sintering performance of hematite iron ore [J]. ISIJ Int, 2007, 47(3): 349–358.

PIMENTA H P, SESHADRI V. Influence of Al2O3 and TiO2 degradation behaviour of sinter and hematite at low temperature on reduction [J]. Ironmaking and Steelmaking, 2002, 29(3): 175–179.

DAS A K, KUMAR A, DE A K, MUKHERJEE T. Characteristics and behavior of high alumina iron ore sinter [C]// Proceedings of the 60th Ironmaking Conference. Warrendle, PA, USA: Iron and Steel Society, 2001: 973–983.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pal, J., Ghorai, S., Nandi, B. et al. Effect of pyroxenite and olivine minerals as source of MgO in hematite pellet on improvement of metallurgical properties. J. Cent. South Univ. 22, 3302–3310 (2015). https://doi.org/10.1007/s11771-015-2870-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-015-2870-6