Abstract

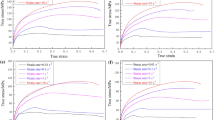

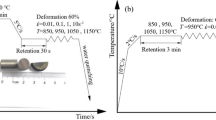

To realize numerical simulation of rolling and obtain the hot forming process parameters for X70HD steel, the flow stress behaviors of X70HD steel were investigated under different temperatures (820−1100 °C) and strain rates (0.01−10 s−1) on a Gleeble-3500 thermo-simulation machine. A new flow stress model was established. The linear and exponential relationship methods were applied to the parameters with respect to temperature and deformation rates. The rise of curve ends under certain conditions was analyzed. The flow stress of X70HD steel predicted by the proposed model agrees well with the experimental results. So, it greatly improves the precision of the metal thermoplastic processing through finite element method and practical application of engineering.

Similar content being viewed by others

References

GAO Xiao-hua, LI Jing, YANG Yong-da, DU Lin-xiu, QIU Chun-lin, LI Hao-ze. Development of high deformability pipeline steel [J]. Rare Met Mater Eng, 2011, 40(s3): 273–275.

ZHANG X Y, GAO H L, ZHANG X Q, YANG Y. Effect of volume fraction of bainite on microstructure and mechanical properties of X80 pipeline steel with excellent deformability [J]. Mater Sci Eng A 2012, 531: 84–90.

LIU Z X, LI X L, CHEN Y S, SONG S J. Development of high deformation X70 pipeline steel plates in NISCO [J]. J Iron Steel Res Int, 2011, 18(s1): 915–919.

LI Ru-tao, ZUO Xiu-rong, HU Yue-yue, WANG Zhen-wei, HU Ding-xu. Microstructure and properties of pipe-line steel with a ferrite/martensite dual-phase microstructure [J]. Mater Charact, 2011, 62: 801–806.

SUNG H K, SOHN S S, SHIN S Y, LEE S, KIM N J, CHON S H. Effects of finish rolling temperature on inverse fracture occurring during drop weight tear test of API X80 pipeline steels [J]. Mater Sci Eng A, 2012, 541: 181–189.

YOU Yang, SHANG Cheng-jia, NIE Wen-jin, SUBRAMANIAN S. Investigation on the microstructure and toughness of coarse grained heat affected zone in X-100 multi-phase pipeline steel with high Nb content [J]. Mater Sci Eng A, 2012, 558: 692–701.

WANG Hong-hong, WU Kai-ming, LEI Xuan-wei, QIAN Yong. Effect of fast cooling process on microstructure and toughness of heat affected zone in high strength pipeline steel X120 [J]. Sci Technol Weld Joi, 2012, 17: 309–313.

POLIAK E I, JONAS J J. A one-parmenter approach to determining the critical conditions for the initiation of dynamic recrystallization [J]. Acta Mater, 1996, 44: 127–136.

SOLHJOO S. Analysis of flow stress up to the peak at hot deformation [J]. Mater Des, 2009, 30: 3036–3040.

QUELENNEC X, BOZZOLO N, JONAS J J, LOGE R. A new approach to modeling the flow curve of hot deformed austenite [J]. ISIJ Int, 2011, 51: 945–950.

ZHANG Xiao-fang, ZHOU Xiao-guang, WANG Guo-dong, WU Di. Research of deformation resistance modeling for Nb bearing steel during compact strip process [J]. Iron Steel, 2007, 42: 37–40.

DU Lin-xiu, ZHANG Zhong-ping, SHE Guang-fu, LIU Xiang-hua, WANG Guo-dong. Austenite recrystallization and controlled rolling of low carbon steels [J]. J Iron Steel Res Int, 2006, 13: 31–35.

WANG Jian, XIAO Hong, XIE Hong-biao, XU Xiu-mei, GAO Ya-nan. Study on hot deformation behavior of carbon structural steel with flow stress [J]. Mater Sci Eng A, 2012, 539: 294–300.

CHEN Fei, CUI Zhen-shan, CHEN Shi-jia. Recrystallization of 30Cr2Ni4MoV ultra-super-critical rotor steel during hot deformation. Part I: Dynamic recrystallization [J]. Mater Sci Eng A, 2011, 528: 5073–5080.

QUAN Guo-zheng, MAO Yuan-ping, LI Gui-sheng, LV Wen-quan, WANG Yang, ZHOU Jie. A characterization for the dynamic recrystallization kinetics of as-extruded 7075 aluminum alloy based on true stress–strain curves [J]. Comput Mater Sci, 2012, 55: 65–72.

JABBARI TALEGHANI M A, RUIZ NAVAS E M, SALEHI M, TORRALBA J M. Hot deformation behaviour and flow stress prediction of 7075 aluminium alloy powder compacts during compression at elevated temperatures [J]. Mater Sci Eng A, 2012, 534: 624–631.

LIN Yong-cheng, LIU Ge. A new mathematical model for predicting flow stress of typical high-strength alloy steel at elevated high temperature [J]. Comput Mater Sci, 2010, 48: 54–58.

JONAS J J, QUELENNEC X, JIANG L, MARTIN E. The avrami kinetics of dynamic recrystallization [J]. Acta Mater, 2009, 57: 2748–2756.

JONAS JJ, QUELENNEC X. Simulation of austenite flow curves under industrial rolling conditions using a physical dynamic recrystallization model [J]. ISIJ Int, 2012, 52: 1145–1152.

LAASRAOUI A, JONAS J J. RecrystalliZation of austenite after deformation at high temperature and strain rates analysis and modeling [J]. Metall Trans A, 1991, 22: 151–160.

WANG Jin, CHEN Jun, ZHANG Bin, ZHAO Zhen, RUAN Xue-yu. The flow stress model of 35CrMo structural steel during hot forming [J]. Journal Shanghai Jiao tong University, 2005, 39: 1784–1791. (in Chinese)

KIM N, CHOI H. The prediction of deformation behavior and interfacial friction under hot working conditions using inverse analysis [J]. J Mater Process Technol, 2008, 208: 211–221.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51304171) supported by the National Natural Science Foundation of China; Project(E2013203248) supported by Natural Science Foundation of Hebei Province of China; Project(NECSR-201209) supported by Open Foundation of the National Engineering Research Center for Equipment and Technology of Cold Rolling Strip, China

Rights and permissions

About this article

Cite this article

Wang, J., Wang, Xg., Yang, Ht. et al. A new mathematical model for predicting flow stress of X70HD under hot deformation. J. Cent. South Univ. 22, 2052–2059 (2015). https://doi.org/10.1007/s11771-015-2728-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-015-2728-y