Abstract

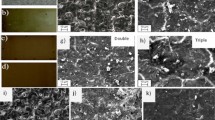

Submicro α-Fe2O3 coatings were formed using electrophoretic deposition (EPD) technique in aqueous media. The zeta potentials of different α-Fe2O3 suspensions with different additives were measured as a function of pH to identify the optimum suspension condition for deposition. Electrophoretic depositions of α-Fe2O3 coatings under different applied electric fields and deposition time were studied and the effects of applied voltages and deposition time on deposition rates and thicknesses were investigated. The particle packing densities of the deposits at various applied voltages and deposition time were also analyzed by a scanning electron microscope (SEM). The results show that crack-free α-Fe2O3 coatings with uniform microstructure and good adherence to the nickel substrates are successfully obtained. Electrophoretic deposited α-Fe2O3 coating from aqueous suspension is a feasible, low-cost and environmental friendly method.

Similar content being viewed by others

References

ZHANG Z, HOSSAIN M F, TAKAHASHI T. Self-assembled hematite (α-Fe2O3) nanotube arrays for photoelectrocatalytic degradation of azo dye under simulated solar light irradiation [J]. Applied Catalysis B: Environmental, 2010, 95(3/4): 423–429.

FELDMANN C. Preparation of nanoscale pigment particles [J]. Advanced Materials, 2001, 13(17): 1301–1303.

BELL A T. The impact of nanoscience on heterogeneous catalysis [J]. Science, 2003, 299: 1688–1691.

JING Z H, WU S H. Preparation and magnetic properties of spherical α-Fe2O3 nanoparticles via a non-aqueous medium [J]. Materials Chemistry and Physics, 2005, 92(2/3): 600–603.

SUN P, WANG W, LIU Y, SUN Y, MA J, LU G. Hydrothermal synthesis of 3D urchin-like α-Fe2O3 nanostructure for gas sensor [J]. Sensors and Actuators B: Chemical, 2012, 173(0): 52–57.

NEGULESCU B, THOMAS L, DUMONT Y, TESSIER M, KELLER N, GUYOT M. Exchange biasing in NiO/NiFe2O4 bilayers [J]. Journal of Magnetism and Magnetic Materials, 2002, 242/245(Part 1): 529–531.

VENZKE S, VAN DOVER R B, PHILLIPS J M, GYORGY E M, SIEGRIST T, CHEN C H, WERDER D, FLEMING R M, FELDER R J, COLEMAN E, OPLIA R. Epitaxial growth and magnetic behavior of NiFe2O4 thin films [J]. Journal of Materials Research, 1996, 11(5): 1187–1198.

CHA H G, KIM C W, KIM Y H, JUNG M H, JI E S, DAS B K, KIM J C, KANG Y S. Preparation and characterization of α-Fe2O3 nanorod-thin film by metal–organic chemical vapor deposition [J]. Thin Solid Films, 2009, 517(5): 1853–1856.

PARK Y J, SOBAHAN K M A, HWANGBO C K. Optical and structural properties of Fe2O3 thin films prepared by ion-beam assisted deposition [J]. Surface and Coatings Technology, 2009, 203(17/18): 2646–2650.

MARUYAMA T, SHINYASHIKI Y. Iron–iron oxide composite thin films prepared by chemical vapor deposition from iron pentacarbonyl [J]. Thin Solid Films, 1998, 333(1/2): 203–206.

DESAI J D, PATHAN H M, MIN S K, JUNG K D, JOO O S. FT-IR, XPS and PEC characterization of spray deposited hematite thin films [J]. Applied Surface Science, 2005, 252(5): 1870–1875.

ZHITOMIRSKY I. Electrophoretic and electrolytic deposition of ceramic coatings on carbon fibers [J]. Journal of the European Ceramic Society, 1998, 18(7): 849–856.

BESRA L, COMPSON C, LIU M. Electrophoretic deposition on non-conducting substrates: The case of YSZ film on NiO–YSZ composite substrates for solid oxide fuel cell application [J]. Journal of Power Sources, 2007, 173(1): 130–136.

PANIGRAHI S, BHATTACHARJEE S, BESRA L, SINGH B P, SINHA S P. Electrophoretic deposition of doped ceria: Effect of solvents on deposition microstructure [J]. Journal of the European Ceramic Society, 2010, 30(5): 1097–1103.

DUSOULIER L, CLOOTS R, VERTRUYEN B, MORENO R, BURGOS-MONTES O, FERRARI B. YBa2Cu3O7-x dispersion in iodine acetone for electrophoretic deposition: Surface charging mechanism in a halogenated organic media [J]. Journal of the European Ceramic Society, 2011, 31(6): 1075–1086.

PFRENGLE A, VON BOTH H, KNITTER R, HAU ELT J. Electrophoretic deposition and sintering of zirconia layers on microstructured steel substrates [J]. Journal of the European Ceramic Society, 2006, 26(13): 2633–2638.

BESRA L, UCHIKOSHI T, SUZUKI TS, SAKKA Y. Application of constant current pulse to suppress bubble incorporation and control deposit morphology during aqueous electrophoretic deposition (EPD)[J]. Journal of the European Ceramic Society, 2009, 29(10): 1837–1845.

TANG F, SAKKA Y, UCHIKOSHI T. Electrophoretic deposition of aqueous nano-sized zinc oxide suspensions on a zinc electrode [J]. Materials Research Bulletin, 2003, 38(2): 207–212.

CH VEZ-VALDEZ A, HERRMANN M, BOCCACCINI A R. Alternating current electrophoretic deposition (EPD) of TiO2 nanoparticles in aqueous suspensions [J]. Journal of Colloid and Interface Science, 2012, 375(1): 102–105.

CORNI I, RYAN M P, BOCCACCINI A R.Electrophoretic deposition: From traditional ceramics to nanotechnology [J]. Journal of the European Ceramic Society, 2008, 28(7): 1353–1367.

CHIBOWSKI S, PASZKIEWICZ M, KRUPA M. Investigation of the influence of the polyvinyl alcohol adsorption on the electrical properties of Al2O3-solution interface, thickness of the adsorption layers of PVA [J]. Powder Technology, 2000, 107(3): 251–255.

SHENG Zhong, WANG Guo Ting. Colloid and surface chemistry [M]. Beijing: Chemical Industry Press; 1991. (in Chinese)

NICHOLSON P S, SARKAR P, HAUNG X. Electrophoretic deposition and its use to synthesize ZrO2/Al2O3 micro-laminate ceramic/ceramic composites [J]. Journal of Materials Science, 1993, 28(23): 6274–6278.

KOURA N, TSUKAMOTO T, SHOJI H, HOTTA T. Preparation of various oxide films by an electrophoretic deposition method: A study of the mechanism [J]. Jpn J Appl Phys, 1995, 34: 1643–1647.

MONDRAG N-CORTEZ P, VARGAS-GUTI RREZ G. Electrophoretic deposition of hydroxyapatite submicron particles at high voltages [J]. Materials Letters, 2004, 58(7/8): 1336–1339.

HAAS-SANTO K, FICHTNER M, SCHUBERT K. Preparation of microstructure compatible porous supports by sol–gel synthesis for catalyst coatings [J]. Applied Catalysis A: General, 2001, 220(1/2): 79–92.

MUNTAZ BEGUM S, RAO M C, APARNA Y, RAO P S, RAVIKUMAR RVSSN. Spectroscopic investigations of Fe3+ doped poly vinyl alcohol (PVA) capped ZnSe nanoparticles [J]. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy, 2012, 98(0): 100–104.

ABDELRAZEK E M, ELASHMAWI I S, LABEEB S. Chitosan filler effects on the experimental characterization, spectroscopic investigation and thermal studies of PVA/PVP blend films [J]. Physica B: Condensed Matter, 2010, 405(8): 2021–2027.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51021063) supported by the National Natural Science Foundation for Innovation Group of China; Project(2012M521540) supported by China Postdoctoral Science Foundation; Project(2013RS4027) supported by the Post Doctoral Scientific Foundation of Hunan Province, China; Project(CSUZC2013023) supported by the Precious Apparatus Open Share Foundation of Central South University, China

Rights and permissions

About this article

Cite this article

Ma, L., Chang, T., Li, Xb. et al. Cathodic electrophoretic deposition of α-Fe2O3 coating. J. Cent. South Univ. 22, 2027–2035 (2015). https://doi.org/10.1007/s11771-015-2725-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-015-2725-1