Abstract

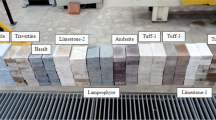

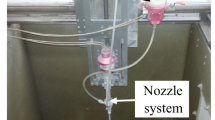

Rock cutting performance of recycling abrasives was investigated in terms of cutting depth, kerf width, kerf taper angle and surface roughness. Gravity separation technique was employed to separate the abrasives and the rock particles. The recycling abrasive particles were then dried and sieved for determination of their disintegration behaviors. Before each cutting with recycling abrasives, the abrasive particles less than 106 μm were screened out. It is revealed that a considerable amount of used abrasives can be effectively reused in the rock cutting. The reusabilities of abrasives are determined as 81.77%, 57.50%, 34.37% and 17.72% after the first, second, third and fourth cuttings, respectively. Additionally, it is determined that recycling must be restricted three times due to the excessive disintegration of abrasives with further recycling. Moreover, it is concluded that cutting depth, kerf width and surface roughness decreases with recycling. No clear trend is found between the kerf taper angle and recycling. Particle size distribution is determined as an important parameter for improving the cutting performance of recycling abrasives.

Similar content being viewed by others

References

YILMAZ G N, KARACA Z, GOKTAN R M, AKAL C. Relative brittleness characterization of some selected granitic building stones: Influence of mineral grain size [J]. Construction and Building Materials, 2009, 23(1): 370–375.

CARRINO L, POLINI W, TURCHETTA S, MONNO M. AWJ to machine free form profiles in natural stone [C]// 2001 WJTA American Waterjet Conf. St Louis, MO: Water Jet Technology Association, 2001: 309–327.

LAUAND C T, MARTIN G R, HENNIES W T, AGUS M. Performance of waterjet cutting system in dimension stone [C]// 2001 WJTA American Waterjet Conf. St Louis, MO: Water Jet Technology Association, 2001: 427–449.

AYDIN G, KARAKURT I, AYDINER K. Investigation of the surface roughness of rocks sawn by diamond sawblades [J]. International Journal of Rock Mechanics and Mining Sciences, 2013, 61: 171–182.

BROOK N, SUMMERS D A. The penetration of rock by high-speed water jets [J]. International Journal of Rock Mechanics and Mining Sciences, 1969, 6(3): 249–258.

NIKONOV G P, GOLDIN Y A. Coal and rock penetration by fine continuous high pressure water jets [C]// 1st International Symposium on Jet Cutting Technology, UK: BHRA, 1972.

CHAKRAVARTHY P S, BABU A R, BABU N R. A fuzzy based approach for selection of process parameters in abrasive waterjet cutting of black granite [C]// 5th Pacific Rim International Conference on Water Jet Technology. New Delhi, India: Allied Publishers Limited, 1998: 108–120.

CHAKRAVARTHY S P, BABU R N. A new approach for selection of optimal process parameters in abrasive water jet cutting [J]. Materials and Manufacturing Processes, 1999, 14(4): 581–600.

LI Xiao-hong, WANG Jian-sheng, LU Yi-yu, YANG Lin, KANG Hui-ming, SUN Jia-jun. Experimental investigation of hard rock cutting with collimated abrasive water jets [J]. International Journal of Rock Mechanics and Mining Sciences, 2000, 37: 1143–1148.

MIRANDA M R, QUINTINO L. Microstructural study of material removal mechanisms observed in abrasive waterjet cutting of calcareous stones [J]. Materials Characterization, 2005, 54(4/5): 370–377.

HLAVAC L M, HLAVACOVA I M, GEMBALOVA L. Experimental method for the investigation of the abrasive water jet cutting quality [J]. Journal of Materials Processing Technology, 2009, 209(20): 6190–6195.

CICCU R, GROSSO B. Improvement of the excavation performance of PCD drag tools by water jet assistance [J]. Rock Mechanics and Rock Engineering, 2010, 43: 465–474.

PON SELVAN C M, RAJU S M N. Assessment of process parameters in abrasive water jet cutting of granite [C]// International Conference on Trends in Mechanical and Industrial Engineering (ICTMIE’2011). Bangkok, 2011: 140–144. http://psrcentre.org/images/extraimages/1211697.pdf.

AYDIN G, KARAKURT I, AYDINER K. An investigation on the surface roughness of the granite machined by abrasive waterjet [J]. Bulletin of Materials Science, 2011, 34(4): 985–992.

ENGIN C I. A correlation for predicting the abrasive water jet cutting depth for natural stones [J]. South African Journal of Science, 2012, 108(9/10): 1–11.

KIM G J, SONG J J, HAN S S, LEE C. Slotting of concrete and rock using an abrasive suspension waterjet system [J]. KSCE Journal of Civil Engineering, 2012, 16(4): 571–578.

ENGIN C I, BAYRAM F, YASITLI E N. Experimental and statistical evaluation of cutting methods in relation to specific energy and rock properties [J]. Rock Mechanics and Rock Engineering, 2012, DOI: 10.1007/s00603-012-0284-4.

KARAKURT I, AYDIN G, AYDINER K. An experimental study on the cut depth of the granite in abrasive waterjet cutting [J]. Materials and Manufacturing Processes, 2012, 27(5): 538–544.

AYDIN G, KARAKURT I, AYDINER K. Cutting performance of abrasive waterjet in granite: Influence of the textural properties [J]. Journal of Materials in Civil Engineering, 2012, 24(7): 944–949.

AYDIN G, KARAKURT I, AYDINER K. Prediction of cut depth of the granitic rocks machined by abrasive waterjet (AWJ) [J]. Rock Mechanics and Rock Engineering, 2012, 46(5): 1223–1235.

KARAKURT I, AYDIN G, AYDINER K. A study on the prediction of kerf angle in abrasive waterjet machining of rocks [J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2012, 226: 1489–1499.

AYDIN G. Recycling of abrasives in abrasive water jet cutting with different types of granite [J]. Arabian Journal of Geosciences, 2014, 7(10): 4425–4435.

BABU K M, CHETTY K O V. A study on recycling of abrasives in abrasive water jet machining [J]. Wear, 2003, 254: 763–773.

ISRM. Rock characterization Testing and monitoring suggested methods [M]. Oxford, UK: Pergamon Press, 1981: 211.

VALANTIN A. Examen des différent procèdes classiques de la nocivité des roches vis-à-vis de l’abatage mécanique [J]. Industrie Minérale Mine, 1974: 133–140.

YARALI O, KAHRAMAN S. The drillability assessment of rocks using the different brittleness values [J]. Tunnelling and Underground Space Technology, 2011, 26: 406–414.

XIE J, TAMAKI J. Parameterization of micro-hardness distribution in granite related to abrasive machining performance [J]. Journal of Materials Processing Technology, 2007, 186: 253–258.

WANG J, GUO D M. The cutting performance in multipass abrasive waterjet machining of industrial ceramics [J]. Journal of Materials Processing Technology, 2003, 133: 371–377.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aydin, G. Performance of recycling abrasives in rock cutting by abrasive water jet. J. Cent. South Univ. 22, 1055–1061 (2015). https://doi.org/10.1007/s11771-015-2616-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-015-2616-5