Abstract

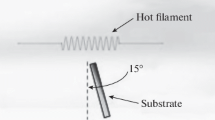

A Ti interlayer with thickness about 300 nm was sputtered on Cu microchannels, followed by an ultrasonic seeding with nanodiamond powders. Adherent diamond film with crystalline grains close to thermal equilibrium shape was tightly deposited by hot-filament chemical vapor deposition (HF-CVD). The nucleation and growth of diamond were investigated with micro-Raman spectroscope and field emission scanning electron microscope (FE-SEM) with energy dispersive X-ray detector (EDX). Results show that the nucleation density is found to be up to 1010 cm−2. The enhancement of the nucleation kinetics can be attributed to the nanometer rough Ti interlayer surface. An improved absorption of nanodiamond particles is found, which act as starting points for the diamond nucleation during HF-CVD process. Furthermore, finite element simulation was conducted to understand the thermal management properties of prepared diamond/Cu microchannel heat sink.

Similar content being viewed by others

References

TUCKERMAN D B. High-performance heat sinking for VLSI [J]. Electron Device Letters, IEEE, 1981, 2(5): 126–129.

HASSAN I, PHUTTHAVONG P, ABDELGAWAD M. Microchannel heat sinks: An overview of the state-of-the-art [J]. Microscale Thermophysical Engineering, 2004, 8(3): 183–205.

MISSAGGIA L J, WALPOLE J N, LIAU Z L, PHILLIPS R J. Microchannel heat sinks for two-dimensional high-power-density diode laser arrays [J]. Quantum Electronics, IEEE Journal of, 1989, 25(9): 1988–1992.

GOODSON K E, KURABAYASHI K, PEASE R F W. Improved heat sinking for laser-diode arrays using microchannels in CVD diamond [J]. IEEE Transactions on Components, Packaging, and Manufacturing Technology-Part B, 1997, 20(1): 104–109.

LIAO M Y, KOIDE Y. Carbon-based materials: Growth, properties, MEMS/NEMS technologies, and MEM/NEM switches [J]. Critical Reviews in Solid State and Materials Sciences, 2011, 36(2): 66–101.

MAY P W. The new diamond age? [J]. Science, 2008, 319(5869): 1490–1491.

LI C, FENG K C, FEI Y J, YUAN H T, XIONG Y, FENG K. The influence of C-60 as intermediate on the diamond nucleation on copper substrate in HFCVD [J]. Applied Surface Science, 2003, 207(1/2/3/4): 169–175.

CHUANG K L, CHANG L, LU C A. Diamond nucleation on Cu by using MPCVD with a biasing pretreatment [J]. Materials Chemistry and Physics, 2001, 72(2): 176–180.

FAN Q H, PEREIRA E, GRÁCIO J. Diamond deposition on copper: Studies on nucleation, growth, and adhesion behaviours [J]. Journal of Materials Science, 1999, 34(6): 1353–1365.

CONSTANT L, SPEISSER C, NORMAND F L. HFCVD diamond growth on Cu(111): Evidence for carbon phase transformations by in situ AES and XPS [J]. Surface Science, 1997, 387(1/2/3): 28–43.

LIU X, WEI Q, Z. U Z, YANG T, ZHAI H. Adherent diamond film deposited on Cu substrate by carbon transport from nanodiamond buried under Pt interlayer [J]. Applied Surface Science, 2013, 265(0): 714–719.

LIU X Z, YU T, WEI Q P, YU Z M, XU X X. Enhanced diamond nucleation on copper substrates by employing an electrostatic self-assembly seeding process with modified nanodiamond particles [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2012, 412(0): 82–89.

HOUŠKA J, PANYALA N R, PEŇA-MÉNDEZ E M, HAVEL J. Mass spectrometry of nanodiamonds [J]. Rapid Communications in Mass Spectrometry, 2009, 23(8): 1125–1131.

YU Z M, LIU X Z, WEI Q P, YANG T M, ZHAI H, TIANG M K. Nanocrystalline diamond matrix deposited on copper substrate by radical species restricted diffusion [J]. Journal of Nanoscience and Nanotechnology, 2013, 13(7): 6910–6916.

BUIJNSTERS J G, VAZQUEZ L, VAN DREUMEL G W G, CELIS J P. Enhancement of the nucleation of smooth and dense nanocrystalline diamond films by using molybdenum seed layers [J]. Journal of Applied Physics, 2010, 108(10): 103514–103519.

CONSTANT L, NORMAND F L. HFCVD diamond nucleation and growth on polycrystalline copper: A kinetic study [J]. Thin Solid Films, 2008, 516(5): 691–695.

LEE S T, LIN Z, JIANG X. CVD diamond films: Nucleation and growth [J]. Materials Science and Engineering R: Reports, 1999, 25(4): 123–154.

GUO L, CHEN G. High-quality diamond film deposition on a titanium substrate using the hot-filament chemical vapor deposition method [J]. Diamond and Related Materials, 2007, 16(8): 1530–1540.

LUX B, HAUBNER R. Diamond deposition on cutting tools [J]. Ceramics International, 1996, 22(4): 347–351.

NORMAND F L, CONSTANT L, EHRET G, SPEISSER C. Generation of carbon tripods on copper by chemical vapor deposition [J]. Journal of Materials Research, 1999, 14(2): 560–564.

NORMAND F L, CONSTANT L, EHRET G, ROMEO M, CHARAI A, SAIKALY W, SPEISSER C. Investigation of carbon aggregates (onions) formed on copper under the conditions of diamond chemical vapour deposition [J]. Philosophical Magazine A-Physics of Condensed Matter Structure Defects and Mechanical Properties, 1999, 79(7): 1739–1756.

IIJIMA S, AIKAWA Y, BABA BAHA Y K. Early formation of chemical vapor deposition diamond films [J]. Applied Physics Letters, 1990, 57(25): 2646–2648.

BULLARD D, LYNCH D. Reduction of titanium dioxide in a nonequilibrium hydrogen plasma [J]. Metallurgical and Materials Transactions B, 1997, 28(6): 1069–1080.

FERRARI A C, ROBERTSON J. Origin of the 1150 cm-1 Raman mode in nanocrystalline diamond [J]. Physical Review B, 2001, 63(12)

KNIGHT D S. Characterization of diamond films by Raman spectroscopy [J]. Journal of Materials Research, 1989, 4: 385–393.

KONIECZNY M. Processing and microstructural characterisation of laminated Ti-intermetallic composites synthesised using Ti and Cu foils [J]. Materials Letters, 2008, 62(17/18): 2600–2602.

DENATALE J F, FLINTOFF J F, HARKER A B. Adhesion improvement in diamond films by microlithographic patterning [J]. Journal of Materials Science, 1992, 27(2): 553–556.

HARTSELL M L, PIANO L S. Growth of diamond films on copper [J]. Journal of Materials Research, 1994, 9: 921–926.

CHEN Y J, YONG T F. Thermal stress and heat transfer characteristics of a Cu/diamond/Cu heat spreading device [J]. Diamond and Related Materials, 2009, 18(2/3): 283–286.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(21271188) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Liu, Xz., Luo, H., Su, X. et al. Preparation of diamond/Cu microchannel heat sink by chemical vapor deposition. J. Cent. South Univ. 22, 835–841 (2015). https://doi.org/10.1007/s11771-015-2590-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-015-2590-y