Abstract

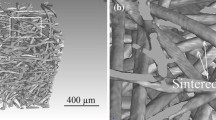

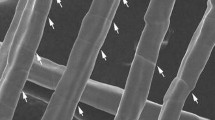

Isothermal sintering experiments were performed on the 316L stainless steel fiber felts with fiber diameters of 8 μm and 20 μm. Surface morphologies of the sintered specimens were investigated by using scanning electron microscopy (SEM) and optical microscopy. The results show that the amount of the sintering necks and the relative densities of the fiber felt increase with the increasing of both the sintering temperature and the sintering time. And the activation energies estimated present a decline at high relative densities for both 8 μm and 20 μm fiber felts. Moreover, the sintering densification of the fiber felts is dominated by volume diffusion mechanism at low temperature and relative densities. As more grain boundaries are formed at higher temperature and relative density, grain boundary diffusion will also contribute to the densification of the specimen.

Similar content being viewed by others

References

ZHANG X, LIN B, LING Y, DONG Y, FANG D, MENG G, LIU X. Highly permeable porous YSZ hollow fiber membrane prepared using ethanol as external coagulant [J]. Journal of Alloys and Compounds, 2010, 494: 366–371.

XU J, LUO G, CHEN G, TAN B. Mass transfer performance and two-phase flow characteristic in membrane dispersion mini-extractor [J]. Journal of Membrane Science, 2005, 249: 75–81.

BO Z, TIANNING C. Calculation of sound absorption characteristics of porous sintered fiber metal [J]. Applied Acoustics, 2009, 70: 337–346.

ZENG J, FAN H, WANG Y, ZHANG S, XUE J, ZHANG C. Oxidized electroplating zinc-covered carbon fibers as microwave absorption materials [J]. Journal of Alloys and Compounds, 2012, 524: 59–62.

TANG Y, ZHOU W, PAN M, CHEN H, LIU W, YU H. Porous copper fiber sintered felts: An innovative catalyst support of methanol steam reformer for hydrogen production [J]. International Journal of Hydrogen Energy, 2008, 33: 2950–2956.

BANHART J. Manufacture, characterisation and application of cellular metals and metal foams [J]. Prog Mater Sci, 2001, 46: 559–U553.

KUMAR A, REDDY R G. Materials and design development for bipolar/end plates in fuel cells [J]. Journal of Power Sources, 2004, 129: 62–67.

MARKAKI A E, GERGELY V, COCKBURN A, CLYNE T W. Production of a highly porous material by liquid phase sintering of short ferritic stainless steel fibres and a preliminary study of its mechanical behaviour [J]. Compos Sci Technol, 2003, 63: 2345–2351.

TANG B, TANG Y, ZHOU R, LU L S, LIU B, QU X M. Low temperature solid-phase sintering of sintered metal fibrous media with high specific surface area [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 1755–1760.

ZHOU W, TANG Y, WAN Z P, LU L S, CHI Y, PAN M Q. Preparation of oriented linear copper fiber sintered felt and its performance [J]. Transactions of Nonferrous Metals Society of China, 2007, 17: 1028–1033.

TANG Y, YUAN W, PAN M, WAN Z. Feasibility study of porous copper fiber sintered felt: A novel porous flow field in proton exchange membrane fuel cells [J]. International Journal of Hydrogen Energy, 2010, 35: 9661–9677.

ZOU C, ZHANG E, LI M, ZENG S. Preparation, microstructure and mechanical properties of porous titanium sintered by Ti fibres [J]. Journal of Materials Science: Materials in Medicine, 2008, 19: 401–405.

KUCZYNSKI G C. Self-diffusion in sintering of metallic particles [J]. AIME Trans, 1949, 185: 169–178.

COBLE R. Sintering crystalline solids. I: Intermediate and final state diffusion models [J]. Journal of Applied Physics, 1961, 32: 787–792.

KOSTORNOV A, FEDORCHENKO I, SHEVCHUK M S, SUKHOZHAK V V. Sintering of metal fiber materials [J]. Soviet Powder Metallurgy and Metal Ceramics, 1972, 11: 33–37.

YOUNG W S, CUTLER I B. Initial sintering with constant rates of heating [J]. Journal of the American ceramic Society, 1970, 53: 659–663.

FANG T T, SHIUE J T, SHIAU F S. On the evaluation of the activation energy of sintering [J]. Materials Chemistry and Physics, 2003, 80: 108–113.

WANG J, RAJ R. Estimate of the activation energies for boundary diffusion from rate-controlled sintering of pure alumina, and alumina doped with zirconia or titania [J]. Journal of the American Ceramic Society, 1990, 73: 1172–1175.

WANG J, RAJ R. Activation energy for the sintering of two-phase alumina/zirconia ceramics [J]. Journal of the American Ceramic Society, 1991, 74: 1959–1963.

GERMAN R M. Sintering theory and practice [M]. New York: Wiley-VCH, 1996: 568.

LIU Z, LOH N, KHOR K, TOR S. Sintering activation energy of powder injection molded 316L stainless steel [J]. Scripta Materialia, 2001, 44: 1131–1137.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51134003) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Feng, P., Liu, Y., Wang, Y. et al. Sintering behaviors of porous 316L stainless steel fiber felt. J. Cent. South Univ. 22, 793–799 (2015). https://doi.org/10.1007/s11771-015-2584-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-015-2584-9