Abstract

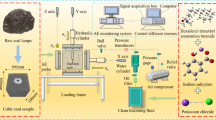

The drum shearer and high pressure water jet combined cutting system is an effective technology to cut hard coal-rock, but one problem of the technology is the choice of pick and nozzle location parameters. In order to solve the problem, the process and mechanism of combined cutting are studied and mining seepage catastrophe theory is used to construct the mathematic and physical model of combined cutting hard coal-rock. Based on the model and detailed analysis of combined cutting mechanism, the single pick and nozzle combined cutting test-bed is built to test the main pick and nozzle location parameters of drum shearer and water jet combined cutting system. Test results show that the best vertical distance between the pick-tip and nozzle center point is the sum of cutting thickness and proper target distance in the Y axial direction; the best horizontal distance is the length between pick-tip point and coal-rock surface bursting crack point in the X axial direction. The best incident angle of water jet should be the same as the bursting crack line’s angle in theory, but considering other important factors comprehensively, it is more reasonable when the incident angle of water jet is 90 °.

Similar content being viewed by others

References

ANIRBAN G, RONALD M B, RAM B. An experimental and numerical study of water jet cleaning process [J]. Journal of Materials Processing Technology, 2011, 211(4): 610–618.

ROBIDOU H, AURACHER H, GARDIN, P. Controlled cooling of a hot plate with a water jet [J]. Experimental Thermal and Fluid Science, 2002, 26(2/4): 123–129.

ZENG R, DU C L, XU R. Portable mixed abrasive water jet equipment for rescue in high gas mine shaft [J]. Journal of Coal Science & Engineering (China), 2011, 17(2): 207–211.

CHANG J Y. Technology of water jet and mode of hydraulic coal mining [J]. Hydraulic Coal Mining & Pipeline Transportation, 2001 (4): 6–9. (in Chinese)

ZHANG Z Z, ZHOU B C. Water jet assistant cutting system of drum shear [J]. Mining Safety & Environmental Protection, 1990(4): 60–64. (in Chinese)

ZHANG L. Application of high pressure water jet technology to coal mine production [J]. Journal of Shanxi Coal-Mining Administrators College, 2000, 13(4): 51–52. (in Chinese)

DUAN X, YU L. Information of rock breaking mechanism in cutting force signals [J]. Journal of China Coal Society, 1993, 18(3): 12–19. (in Chinese)

DUAN X, YU L, CHENG D Z. Composite laminated plate characteristics of auto-control water jet pick’s mechanism [J]. Chinese Journal of Rock Mechanics and Engineering, 1993, 12(3): 222–231. (in Chinese)

DUAN X. Nonlinear dynamics research on auto-control water jet pick [D]. Xuzhou: China University of Mining and Technology, 1991. (in Chinese)

CHANG Z X, ZHAO Y S, HU Y Q. Theoretic and experimental studies of the coupling of seepage flow and 3D stresses in fractured rock masses [J]. Chinese Journal of Rock Mechanics and Engineering, 2004, 23(7): 4907–4911.

CHANG Z X, ZHAO Y S, HU Y Q. Theoretic and experimental studies on seepage law of single fracture under 3D stresses [J]. Chinese Journal of Rock Mechanics and Engineering, 2004, 23(2): 620–624.

LIANG Y P. Study on the mechanism of coal failure by drilling of high pressure water jetting [D]. Qingdao: Shandong University of Science and Technology, 2007. (in Chinese)

LI G S, NIU J L, SONG J. Abrasive water jet perforation: An alternative approach to enhance oil production [J]. Petroleum Science and Technology, 2004, 22(5): 491–504.

LI G S, ZHANG D B, HUANG, Z W. Self-excited oscillating water injection: Mechanisms and experiments [J]. Petroleum Science and Technology, 2003, 21(1): 145–155.

LI G S, HUANG, Z W, ZHANG D B. Study of treatment of near well-bore formation processed with high pressure rotating water jets [J]. Petroleum Science and Technology, 2002, 20(10): 961–972.

MIAO X X, LIU W Q, CHEN Z Q. Mining seepage theory [M]. Beijing: Science Publishing Company Press, 2004. (in Chinese)

WAN S W, XU J H, LI C. Study on the chaotic behavior of mining rock seepage system [J]. Mining Science and Technology, 2011, 21(6): 755–759.

LIU S Y. Model test of the cutting properties of a shearer drum [J]. Mining Science and Technology, 2009, 19(1): 74–78.

LIU S Y, DU C L, CUI X X. Experimental research on picks arrangement of shearer drum [J]. Journal of Central South University: Science and Technology, 2009, 40(5): 1281–1287. (in Chinese)

LIU S Y, DU C L, CUI X X. Characteristics of different rocks cut by helical cutting mechanism [J]. Journal of Central South University of Technology, 2011, 18(5): 1518–1524.

LIU S Y, DU C L, CUI X X. Method to determine installing angle of conical point attack pick [J]. Journal of Central South University of Technology, 2011, 18(6): 1994–2000.

XU R. Study on water jet assistant cutting technology of road header [D]. Xuzhou: China University of Mining and Technology, 2011: 130–133. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2012AA062104) supported by the National High Technology Research and Development Program of China; Project(201104583) supported by the Postdoctoral Special Funded Projects, China

Rights and permissions

About this article

Cite this article

Zeng, R., Du, Cl., Chen, Rj. et al. Reasonable location parameters of pick and nozzle in combined cutting system. J. Cent. South Univ. 21, 1067–1076 (2014). https://doi.org/10.1007/s11771-014-2038-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-014-2038-9