Abstract

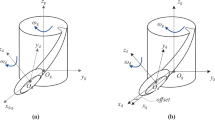

A slotting method for cosine gears was proposed by using the involute cutter based on the conjugate theories of digital surface and gear meshing. The slotting model between the cosine tooth surface represented by discrete points and the cutter figuration determined by analytic function was built for their geometrical relationship and conjugate motion during the machining process. Conjugate points in the cutter section corresponding to the discrete points on the cosine gear tooth surface and the conjugate movements were solved. By using the flexible control of the CNC procedure, the active control of the cutting trace of the slotting cutter was accomplished and the envelop forming of the cosine gear was obtained. Based on the software C++ and Matlab, the computer aided manufacturing (CAM) system of the cosine gear was developed, and the simulation of the slotting process was accomplished. Several examples were provided to illustrate the approach. The result of the simulation demonstrates that the proposed slotting method is feasible.

Similar content being viewed by others

References

LITVIN F L, FUENTES A, ZANZI C, PONTIGGIA M. Design, generation, and stress analysis of two versions of geometry of face-gear drives [J]. Mechanism and Machine Theory, 2002, 37(10): 1179–1211.

LITVIN F L, FUENTES A, HAYASAKA K. Design, manufacture, stress analysis, and experimental tests of low-noise high endurance spiral bevel gears [J]. Mechanism and Machine Theory, 2006, 41(1): 83–118.

FONG Z H, CHIANG T W, TSAI C W. Mathematical model for parametric tooth profile of spur gear using line of action [J]. Mathematical and Computer Modelling, 2002, 36(4/5): 603–614.

KAPELEVICH A. Geometry and design of involute spur gears with asymmetric teeth [J]. Mechanism and Machine Theory, 2000, 35(1): 117–130.

YANG S C. Applying envelope theory and deviation function to tooth profile design [J]. Mechanism and Machine Theory, 2007, 42(3): 162–174.

CHEN Bing-kui, ZHONG Hui, LIU Jing-ya, LI Chao-yang, FANG Ting-ting. Generation and investigation of a new cycloid drive with double contact [J]. Mechanism and Machine Theory, 2012, 49(3): 270–283.

CHEN C F, TSAY C B. Tooth profile design for the manufacture of helical gear sets with small numbers of teeth [J]. International Journal of Machine Tools & Manufacture, 2005, 45(12/13): 1531–1541.

LITVIN F L, GONZALEZ-PEREZ I, YUKISHIMA K, FUENTES A, HAYASAKA K. Generation of planar and helical elliptical gear by application of rack-cutter, hob, and shaper [J]. Computer Methods and Application of Mechanical Engineering, 2007, 196(41/44): 4321–4336.

BAIR B W. Computerized tooth profile generation of elliptical gears manufactured by shaper cutters [J]. Journal of Materials Processing Technology, 2002, 122(2/3): 139–147.

FENG Xian-ying, LI Hui, AI Xing. CNC flexible generating specific gear tooth profile based on standard involute gear hob [J]. Chinese Journal of Mechanical Engineering, 2004, 17(3): 377–380. (in Chinese)

LI Ting, PAN Cun-yun. On grinding manufacture technique and tooth contact and stress analysis of ring-involute spherical gears [J]. Mechanism and Machine Theory, 2009, 44(10): 1807–1825.

WANG Fu-lin, YI Chuan-yun, YANG Shu-zi, CHEN Jing. Slotting method for two-dimensional digital gear tooth surfaces [J]. Chinese Journal of Mechanical Engineering, 2008, 44(6): 88–94. (in Chinese)

YU Wen-hua, ZHOU Yun-fei, LI Zuo-qing. CNC generating method with standard hob for arbitrary gear profile [J]. China Mechanical Engineering, 2000, 11(5): 555–557. (in Chinese)

WANG Ai-qun, FENG Xian-ying, AI Xing. Study on generation of specific gear and simulation of machining process [J]. Chinese Journal of Mechanical Engineering, 2003, 39(1): 143–148. (in Chinese)

CHEN Bing-kui, WANG Shu-yan, JIANG Xu-jun, FANG Ting-ting, LI Zhao-yang. Manufacturing method for the conic cycloidal gear pair [J]. Chinese Journal of Mechanical Engineering, 2007, 43(1): 147–151. (in Chinese)

LUO Shan-ming, WU Yue, WANG Jian. The generation principle and mathematical models of a novel gear drive [J]. Mechanism and Machine Theory, 2008, 43(12): 1543–1556.

LUO Shan-ming, WU Xiao-ling, XU Pan, WANG Jian. Research on generation of cosine tooth profile based on two-step machining method [J]. Chinese Journal of Mechanical Engineering, 2011, 47(9): 175–181. (in Chinese)

ZHOU Kai-hong, ZHOU Xiao-yan. Envelopment-approach to manufacturing of spiral bevel gears based on computer numerical control cutting machine [J]. China Mechanical Engineering, 2010, 21(20): 2438–2444. (in Chinese)

LITVIN F L, FUENTES A. Gear geometry and applied theory [M]. 2nd Edition. New York: Cambridge University Press, 2004: 105–115.

SU Zhi-jian, WU Xu-tang. Manufacture of hypoid gear based on computer numerical control cutting machine [J]. Chinese Journal of Mechanical Engineering, 2007, 43(5): 57–63. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(51205335, 50975242, 51375411) supported by the National Natural Science Foundation of China; Project(2013J01209) supported by the Natural Science Foundation of Fujian Province, China

Rights and permissions

About this article

Cite this article

Wang, J., Luo, Sm. & Xu, P. Mathematical model of slotting manufacture and simulation for cosine gears. J. Cent. South Univ. 21, 933–941 (2014). https://doi.org/10.1007/s11771-014-2021-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-014-2021-5