Abstract

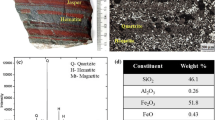

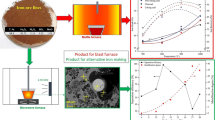

A new iron-making process using carburized pre-reduced iron ore pellets and microwave heating is investigated. The pre-reduced pellets, with a porous structure, and fine particles are carburized homogeneously at 400–650 °C in a CO atmosphere. The carburized carbon not only acts reaction as a reduction agent, but also absorbs microwave in the reduction process. Hence, the carburized pre-reduced pellets can be rapidly reduced by microwave heating. There are three procedures involved in the process, namely, gas-based pre-reduction, low-temperature carburization and deep reduction by microwave heating. Carburized pre-reduced iron ore pellets show a rapid temperature rise that is twice as fast as the results for pre-reduced pellets in the laboratory. This not only improves the efficiency of the microwave heating, but also accelerates the reduction of iron oxides. The temperature of the pre-reduced pellets rises to 1050 °C in 45 min when the carburization rate is 2.02%, and the metallization rate and compressive strength reach 94.24% and 1725 N/pellet, respectively.

Similar content being viewed by others

References

METAXAS A C, MEREDITH R J. Industrial microwave heating [M]. London: Peter Peregrinus, 1983: 296–313.

OLIVER C. Microwave dielectric heating in synthetic organic chemistry [J]. Chem Soc Rev, 2008, 37: 1127–1139.

MORALES M E, JUNCO L, MALO A, GARCIA H S. Dielectric properties of foods: Reported data in the 21st century and their potential applications [J]. Food Science and Technology, 2010, 43: 1169–1179.

BAI Cheng-guang, REN Wei, QIU Gui-bao, HU Mei-long, CHEN Deng-fu, WEN Liang-ying. The review of microwave applications in metallurgical process in China [J]. ISIJ International, 2007, 47: 528–532.

ZHANG Xun-li, HAYWARD D O. Applications of microwave dielectric heating in environment-related heterogeneous gas-phase catalytic systems [J]. Inorganica Chimica Acta. 2006, 359: 3421–3433.

SAIDI A, AZARI K. Carbothermic reduction of zinc oxide concentrate by microwave [J]. J Mater Sci Technol, 2005, 21(5): 724–728.

POURGHAHRAMANI P, FORSSBERG E. Effects of mechanical activation on the reduction behavior of hematite concentrate [J]. Int J Miner Process, 2007, 82: 96–105.

ISHIZAKI K, NAGATA K. Selectivity of microwave energy consumption in the reduction of Fe3O4 with carbon black in mixed powder [J]. ISIJ International, 2007, 47(6): 811–816.

ELIAS F N, RUTH H G A K. Al2O3/mullite/SiC powders synthesized by microwave-assisted carbothermal reduction of kaolin [J]. Ceramics International, 2001, 27(7): 815–819.

DUAN Bi-lin, ZENG Ling-ke, LIU Yan-chun, SHUI An-ze, WANG Hui, ZHANG Hai-wen. The application and status of microwave-assisted firing technology in the inorganic materials [J]. Journal of ceramics, 2006, 27(1): 120–124.

KU S H, SIORES E, TAUBE A, BALL J. Productivity improvement through the use of industrial microwave technologies [J]. Computer & Industrial Engineering, 2002, 42 (4): 281–290.

HWANG J Y, HUANG Xiao-di. Microwave heating method and apparatus for iron oxide reduction. United States Patent, US 2008/0087135 A1 [P]. 2008-04-17

STIR M, ISHIZAKI K, VAUCHER S, NICULA R. Mechanism and kinetics of the reduction of magnetite to iron during heating in a microwave E-field maximum [J]. Journal of Applied Physics, 2009, 105(12): 901–904

HU Bing, HUANG Zhu-cheng, JIANG Tao, PENG Hu. New method of direct reduction on iron concentrate oxidized pellets by microwave heating [J]. Iron & Steel, 2012, 47(1): 14–18.

JONES D A, KINGMAN S W, WHITTLES DN, LOWNDES I S. Understanding microwave assisted breakage [J]. Minerals Engineering, 2005, 18(7): 659–669.

HUA Yi-xin, LIU Chun-peng. Heating rate of minerals and compounds in microwave field [J]. Transactions of Non-ferrous Metal Society, 1996, 6(1): 35–40.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(NCET-04-0748) supported by the New Century Excellent Talent Planning of China

Rights and permissions

About this article

Cite this article

Hu, B., Huang, Zc., Yi, Ly. et al. Direct reduction of carburized pre-reduced pellets by microwave heating. J. Cent. South Univ. 21, 351–357 (2014). https://doi.org/10.1007/s11771-014-1947-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-014-1947-y