Abstract

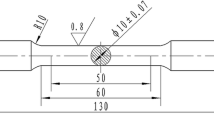

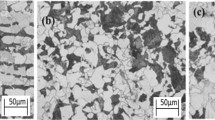

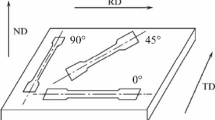

Pre-heat treatment is a vital step before cold ring rolling and it has significant effect on the microstructure and mechanical properties of rolled rings. The 100Cr6 steel rings were subjected to pre-heat treatment and subsequent cold rolling process. Scanning electron microscopy and tensile tests were applied to investigate microstructure characteristic and mechanical property variations of 100Cr6 steel rings undergoing different pre-heat treatings. The results indicate that the average diameter of carbide particles, the tensile strength and hardness increase, while the elongation decreases with the decrease of cooling rate. The cooling rate has minor effect on the yield strength of sample. After cold ring rolling, the ferrite matrix shows a clear direction along the rolling direction. The distribution of cementite is more homogeneous and the cementite particles are finer. Meanwhile, the hardness of the rolled ring is higher than that before rolling.

Similar content being viewed by others

References

HUA Lin, HUANG Xing-gao, ZHU Chun-dong. Ring rolling theory and technology [M]. Beijing: China Machine Press, 2001: 1–2,27, 80. (in Chinese)

HU Zheng-huan, HUA Lin. Technology of rotary metal forming [M]. Beijing: Chemical Industry Press, 2010: 221–224, 227–229. (in Chinese)

JOHNSON W, MACLEOD I, NEEDHAM G. An experimental investigation into the process of ring or metal type rolling [J]. International Journal of Mechanical Sciences, 1968, 10(6): 455–468.

HAWKYARD J B, JOHNSON W, KIRHLAND J, APPLETON E. Analyses for roll force and torque in ring rolling with some supporting experiments [J]. International Journal of Mechanical Sciences, 1973, 15(11): 873–893.

YANG D Y, KIM K H. Rigid-plastic finite element analysis of plane strain ring rolling [J]. International Journal of Mechanical Sciences, 1988, 30(8): 571–580.

HAHN Y H, YANG D Y. UBET analysis of roll torque and profile formation during the profile ring-rolling of rings having rectangular protrusions [J]. Journal of Materials Processing Technology, 1991, 26(3): 267–280.

HUA L, ZHAO Z Z. The extremum parameters in ring rolling [J]. Journal of Materials Processing Technology, 1997, 69(1/2/3): 273–276

YAN F L, HUA L, WU Y Q. Planning feed speed in cold ring rolling [J]. International Journal of Machine Tools and Manufacture, 2007, 47: 1695–1701.

HAN Xing-hui, HUA Lin. 3D FE modeling of cold rotary forging of a ring workpiece [J]. Journal of Materials Processing Technology, 2009, 209(12/13): 5353–5362.

HUA L, ZUO Z J, PAN L B. Research on following motion rule of guide roller in cold rolling groove ball ring [J]. Journal of Materials Processing Technology, 2007, 177: 743–746.

HUA L, QIAN D S, PAN L B. Deformation behaviors and conditions in L-section profile cold ring rolling [J]. Journal of Materials Processing Technology, 2009, 209: 5087–5096.

GUO L G, YANG H. Research on plastic deformation behaviour in cold ring rolling by FEM numerical simulation [J]. Modeling and Simulation in Materials Science and Engineering, 2005, 13(7): 1029–1046.

WANG W, YAN W, ZHU L, HU P, SHAN Y Y, YANG K. Relation among rolling parameters microstructures and mechanical properties in an acicular ferrite pipeline steel [J]. Materials and Design, 2009, 30: 3436–3443.

RYTTBERG K, WEDEL M K, RECINA V, DAHLMAN P, NYBORG L. The effect of cold ring rolling on the evolution of microstructure and texture in 100Cr6 steel [J]. Materials Science and Engineering: A, 2010, 527: 2431–2436.

SHAO Y C, HUA L, WEI W T, WU M. Numerical and experimental investigations into strain distribution and metal flow of low carbon steel in cold ring rolling [J]. Materials Research Innovations, 2013, 7(1): 49–57(9).

WU M, HUA L, SHAO Y C. Influence of the annealing cooling rate on the microstructure evolution and deformation behaviours in the cold ring rolling of medium steel [J]. Materials and Design, 2011, 32: 2292–2300.

WU Min, Research on microstructure evolution in pre-heat treatment and cold ring rolling [D]. Wuhan: Wuhan University of Technology, 2010. (in Chinese)

CUI Zhong-xin, LIU Bei-xing. Metallographic and principles of heat treatment. Harbin: Harbin Institute of Technology Press, 1998: 188–189. (in Chinese)

SETO Hao. Bearing steel [M]. Beijing: Metallurgical Industry Press, 2003.

LIU Zong-chang. Pearlite transformation and annealing [M]. Beijing: Chemical Industry Press, 2007: 19, 21. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2011CB706605) supported by the National Basic Research Program of China; Project(2011CDA12) supported by the Innovative Research Groups of the Natural Science Foundation of Hubei Province, China; Projects(2012-Ia-017, 2013-IV-014) supported by the Fundamental Research Funds for the Central Universities, China

Rights and permissions

About this article

Cite this article

Wei, Wt., Wu, M. Effect of annealing cooling rate on microstructure and mechanical property of 100Cr6 steel ring manufactured by cold ring rolling process. J. Cent. South Univ. 21, 14–19 (2014). https://doi.org/10.1007/s11771-014-1909-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-014-1909-4