Abstract

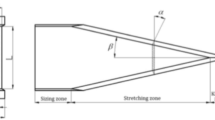

Due to the variation of the blade cross-section, the deformation stress and strain of the workpiece keep changing during the rolling process and the conventional rolling theory is no longer valid. The complexity and diversity of the blade cross-section determine it impossible to establish an universal theoretical model for the rolling process. Finite element analysis (FEA) provides a perspective solution to the prediction. The FEA software DEFORM was applied to discovering the deformation, stress, strain and velocity field of the variable cross-section workpiece, and the effects of friction coefficient and rolling speed during the rolling process. which indicates that the average rolling force at friction coefficient of 0.4 is 6.5% higher than that at 0.12, and the rolling velocity has less effect on the equivalent stress and strain distribution, which would confer instructive significance on the theoretical study as well as the engineering practice.

Similar content being viewed by others

References

HU Zheng-huan, LIU Jin-ping. Present status and prospect of part rolling technology [J]. Aeronautical Manufacturing Technology, 2004(3): 49–51. (in Chinese)

SHU Xue-dao, PENG Wen-fei, HU Zheng-huan The study of rolling force on forming large-sized shaft-part by cross wedge rolling [J]. Journal of Plasticity Engineering, 2009, 16(1): 102–114. (in Chinese)

SUN Ji-wang, FU Jian-hua, LI Yong-tang. Analysis of new rotary-forging process of rear-semi axis using Deform-3D [J]. Forging & Stamping Technology, 2009, 34(3): 160–163. (in Chinese)

CARRUTH M A, ALLWOOD J M. The development of a hot rolling process for variable cross-section I-beams [J]. Journal of Materials Processing Technology, 2012, 212: 1640–1653.

PENG Wen-fang, LI Qiang, YAN Yu. FEA analysis on 600MPa trip steel variable section roll forming with protrusion and hole [J]. Advanced Materials Research, 2012, 457/458: 299–303.

LV Cheng, ZHANG Li-wen, MU Zheng-jun, TAI Qing-an, ZHENG Qu-ying. 3D FEM simulation of multi-stage forming process of a gas turbine compressor blade [J]. Journal of Material Processing Technology, 2008, 198(2): 463–470.

ZHANG Jin-ling, CUI Zhen-shan. Continuous FEM simulation of multi-pass plate hot rolling suitable for plate shape analysis [J]. Journal of Central South University, 2011, 18: 16–22.

BACKER V, KLOCKE F, WEGNER H, TIMMER A, GRZHIBOVSKIS R, RJASANOW S. Analysis of the deep rolling process on turbine blades using the FEM/BEM-coupling [J]. IOP Conference Series: Materials Science and Engineering, 2010, 10: 012134.

WEISS T, VOIGT M, SCHLUMS H, MUCKE R, BECKER K, VOGELER K. Probabilistic finite-element analyses on turbine blades [C]// Proceedings of the ASME Turbo Expo. New York: American Society of Mechanical Engineers, 2009: 1093–1102.

LIU Yu-li. 3D FEM Analysis of forming laws in precision forging process of blade [D]. Xi’an: Northwestern Polytechnical University, 2001. (in Chinese)

SHAHANI A R, SETAYESHII S, NODAMAIE S A. Prediction of influence parameters on the hot rolling process using finite element method and neural network [J]. Journal of Material Processing Technology, 2009, 209(4): 1920–1935.

GONZALEZ J P, CASQUERO F J E, MATO J V, GONZALEZ-POSADA M A. Blade bearing friction and fatigue mathematical model [C]// 2008 Proceedings of the STLE/ASME International Joint Tribology Conference. New York: American Society of Mechanical Engineers, 2009: 427–431.

WANG Xiao, FAN Xiao-bo, LIU Hui-xia. Research on cold taper-rolling law of the spiral blade based on finite element method [J]. Materials Science Forum, 2008, 575–578: 305–310.

CAO Jie, LV Jing, WANG Qi. Modeling and simulating of planar multi-body systems with rolling resistance and Coulomb friction [J]. Journal of Beijing University of Aeronautics and Astronautics, 2012, 38: 410–415.

van der STEEN R, LOPEZ I, NIJMEIJER H, SCHMEITZ A J C, de BRUIJN B. Experimental and numerical study of friction and braking characteristics of rolling tires [J]. Tire Science & Technology, 2011, 39: 62–78.

HUANG M N, PAN S C, TZOU G Y, SYU S W. Analysis of asymmetrical cold and hot bond rolling of unbounded clad sheet under constant shear friction [J]. Journal of Materials Processing Technology, 2006, 177: 114–120.

PARVIZI A, ABRINIA K, SALIMI M. Slab analysis of ring rolling assuming constant shear friction [J]. Journal of Materials Engineering and Performance, 2011, 20: 1505–1511.

TAN Xin-cai, YAN Xiu-tian, JUSTER N P, RAGHUNATHAN S, WANG Jian. Dynamic friction model and its application in flat rolling [J]. Journal of Materials Processing Technology, 2008, 207: 222–234.

KIREENKOV A A. Coupled models of sliding and rolling friction [J]. Doklady Physics, 2008, 53: 233–236.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(F12-256-1-00) supported by the Key Laboratory Program of Shenyang City, China; Project(N090403006) supported by the Seed Cultivation Fund, China; Project supported by the Research Innovation Fund for Young Teachers, China

Rights and permissions

About this article

Cite this article

Kong, Xw., Li, J. & Li, B. Finite element analysis of rolling process for variable cross-section blade. J. Cent. South Univ. 20, 3431–3436 (2013). https://doi.org/10.1007/s11771-013-1867-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-013-1867-2