Abstract

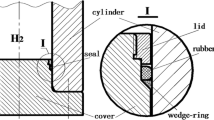

To solve the problem of sealing between the barrel and the rubber ring of shell body during an launching process of aerodynamic extinguishing cannon, a rubber sealing model with bionic dimpled characteristics was established based on the theory of bionic dimpled drag reduction and the principle of rubber sealing. In condition that the bionic dimpled characteristic diameters were 1, 2, 3, 4, and 5 mm, respectively, by numerical simulation, the influence of the installing compression of the rubber sealing ring on its surface stress and deformation was analyzed, and sealing performance of the rubber ring with different diameters of bionic dimpled was studied. The results show that the deformation of rubber ring appears prominent nonlinear characteristics when compression is increased from 1.5 mm to 2.5 mm. When the compression is 2.5 mm, the equivalent compression stress on the sealing areas of both sides of the rubber seal is greater than the working pressure of aerodynamic extinguishing cannon, which could meet the sealing requirement and would not cause leakage. So the rubber sealing ring with bionic dimpled surface possesses a good sealing characteristic and has no negative effect on the sealing of shell body; When the compression is 2.5 mm, the larger equivalent stress on the edge of sealing ring and the more even stress distribution in the high pressure area are generated due to the smaller compressive stress on the bionic dimple areas, which lays a foundation for the drag reduction characteristics of the shell body’s rubber ring with bionic dimpled surface.

Similar content being viewed by others

References

ZHAO Gang, SHU Hai-sheng, SUN Chun-yang, GU Yun-qing, LIU Shao-gang. A buffering system based on friction and energy absorption theory for aerodynamic extinguishing cannon [J]. Journal of Shenyang University of Technology, 2011, 33(4): 387–393. (in Chinese)

TZENG J, TSUN Wei. Dynamic response of cantilevered rail guns attributed to projectile/gun interaction-theory [J]. IEEE Transactions on Magnetics, 2007, 43(1): 207–213.

YI Peng, YUAN Rui-bo, LUO Jing, ZENG Hao. Sliding mode control applied to aerodynamic servo system [J]. Applied Mechanics and Materials, 2012, 233: 109–113.

ZENG Hao, YUAN Rui-bo, HE Zu-shun, YI Peng. Speed servo control of pneumatic manipulator based on sliding mode variable structure control [J]. Applied Mechanics and Materials, 2012, 233: 158–162.

HAN Jun, PAN Yuan, HE Jun-jia. Study of employing railguns in close-in weapon systems [J]. IEEE Transactions on Magnetics, 2009, 45(1): 641–645.

LAWANWONG K, PREMANOND V. The study reduction of spring-back in U bending die process [C]// The 2nd International Conference on Mechanical and Electronics Engineering. Kyoto, Japan, 2 2010: 284–288.

MIYAWAKI K, MORI S, SAKURADA A, NAGANAWA A, KIMURA Y, SHIBUYA Y, OBINATA G. High precise positioning control for block spring motor [C]// 2008 International Symposium on Micro-NanoMechatronics and Human Science. Nagoya, Japan, 2008: 441–446.

KARASZKIEWICZ A. Geometry and contact pressure of an O-ring mounted in a seal groove [J]. Industrial and Engineering Chemistry Research, 1990, 29(10): 2134–2137.

DIANY M, AISSAOUI H. Finite element analysis for short term O-ring relaxation [J]. Jordan Journal of Mechanical and Industrial Engineering, 2011, 5(6): 478–482.

LIAO Chuan-jun, SUO Shuang-fu, WANG Yu-ming, HUANG Wei-feng, LIU Ying. Study on stick-slip friction of reciprocating O-ring seals using acoustic emission techniques [J]. Tribology Transactions, 2012, 55(1): 43–51.

LINGERKAR K, KHONSARI M M. On the effects of sliding velocity and operating pressure differential in rotary O-ring seals [J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2010, 224(7): 649–657.

YANG B, SALANT R F. Elastohydrodynamic lubrication simulation of O-ring and U-cup hydraulic seals [J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2011, 225(7): 603–610.

TAN Xin-ping, HE Zu-shun, LIN Yi-jie, WU Song-tao. Study of static analysis for lifting arm device of conveying manipulator based on inventor FEA module [J]. Hydromechatronics Engineering, 2012, 40(24): 81–84.

ZHANG Yi-bo, HE Zu-shun, YUAN Rui-bo, ZHANG Li. The modeling and simulation of water hydraulic overflow valve with giant magnetostrictive actuator [J]. Applied Mechanics and Materials, 2012, 233: 163–167.

GREEN I, ENGLISH C. Analysis of elastomerie O-ring seals in compression using the finite element method [J]. Tribology Transactions, 1992, 35(1): 83–88.

GENT A N, KIM W. Bulging of rubber through apertures [J]. Rubber Chemistry and Technology, 1991, 64(5): 813–821.

HU Dian-yin, WANG Rong-qiao, REN Quan-bin, HONG Jie. Finite element analysis of O-ring seal structure [J]. Journal of Beijing University of Aeronautics and Astronautics, 2005, 31(2): 255–260. (in Chinese)

ACHENBACH M. Service life of seals-numerical simulation in sealing technology enhances prognoses [J]. Computational Materials Science, 2000, 19(1/2/3/4): 213–222.

REN Lu-quan. Progress in the bionic study on anti-adhesion and resistance reduction of terrain machines [J]. Science in China (Series E): Technological Sciences, 2009, 52(2): 273–284.

REN Lu-quan, HAN Zhi-wu, LI Jian-qiao, TONG Jin. Experimental investigation of bionic rough curved soil cutting blade surface to reduce soil adhesion and friction [J]. Soil and Tillage Research, 2006, 85(1/2): 1–12.

BECHERT D W, BRUSE M, HAGE W. Experiments with three-dimensional riblets as an idealized model of shark skin [J]. Experiments in Fluids, 2000, 28(5): 403–412.

VISWANATH P R. Aircraft viscous drag reduction using riblets [J]. Progress in Aerospace Sciences, 2002, 38(6/7): 571–600.

WANG Jing, ZHAGN Cheng-chun, REN Lu-quan, HAN Zhi-wu. Numerical simulation on flow control for drag reduction of revolution body using dimpled surface [J]. Journal of China Ordnance, 2011, 7(1): 59–64.

GU Yun-qing, ZHAO Gang, ZHENG Jin-xing, ZHANG Shu, LI Zhao-yuan, YAO Jian-jun. Experiment study and numerical simulation on drag reduction characteristic of bionic jetting surface [C]// 2012 International Conference on Maritime Technology. Harbin, China, 2012: 195–199

ZHAO Gang, GU Yun-qing, ZHAO Hua-lin, XIA Dong-lai, YAO Jian-jun. Numerical simulation of the drag reduction characteristics of a bionic jet surface aperture coupled with jet speed [J]. Journal of Harbin Engineering University, 2012, 33(8): 1001–1007. (in Chinese)

GU Yun-qing, ZHAO Gang, ZHENG Jin-xing, ZHANG Shu, RU Jing, LIU Ming-ming, YAO Jian-jun. Drag reduction characteristics on jetting surface with jet angle-jet velocity coupling[J]. Journal of Xi’an Jiaotong University, 2012, 46(9): 71–77. (in Chinese)

ZHAO Gang, GU Yun-qing, XU Guo-yu, XIA Dong-lai, ZHAO Hua-lin, YAO Jian-jun. Experimental study on drag reduction characteristics of bionic jet surface [J]. Journal of Central South University: Science and Technology, 2012, 43(8): 3007–3012. (in Chinese)

GU Yun-qing, ZHAO Gang, ZHAO Hua-lin, ZHENG Jin-xing, WANG Fei, XIAO Lei, LIU Wen-bo. Simulation study on drag reduction characteristics of bionic jet flow based on shark gill [J]. Acta Armamentarii, 2012, 33(10): 1230–1236. (in Chinese)

ZHAO Gang, GU Yun-qing, ZHENG Jin-xing, YANG Li-ming, LIU Hao, XIE Zhi-chao, YAO Jian-jun. A testing platform based on bionics drag reduction theory for friction resistance [J]. Communications in Information Science and Management Engineering, 2012, 2(5): 34–39

GU Yun-qing, ZHAO Gang, ZHENG Jin-xing, WANG Fei, LI Zhao-yuan, LIU Wen-bo, ZHAO Hua-xing. Characteristics of drag reduction on coupling of jet surface main flow field velocity and jet velocity [J]. Journal of Central South University: Science and Technology, 2012, 43(12): 4713–4721. (in Chinese)

ZHAO Gang, GU Yun-qing, ZHENG Jin-xing, XIA Dong-lai, ZHAO Hua-lin, YANG Li-ming, YAO Jian-jun. The study of the small drag reduction testing platform [C]// The 2nd International Conference on Artificial Intelligence, Management Science and Electronic Commerce. Zhengzhou, China, 2011: 6021–6024.

GU Yun-qing, ZHAO Gang, LIU Hao, WANG Yan-ming, LI Zhao-yuan, LIU Wen-bo, ZHAO Jian-ying, LI Fang. Characteristics of drag reduction of bionic dimpled surface of shell rubber ring of aerodynamic extinguishing cannon [J]. Journal of Jilin University: Engineering and Technology Edition, 2013, 43(4): 983–990. (in Chinese)

SHIN Joong-ho, KIM Chang-hyun, YUN Pyeong-hwa, KWON Soon-man. Dual cycloid gear mechanism for automobile safety pretensioners [J]. Journal of Central South University, 2012, 19(2): 365–373.

LI Rong, LUO Jing, HE Zu-shun, PENG Zhi-fei. Simulation and analysis on the molding pressure roller of lead flake based on AMESim and ADAMS [J]. Applied Mechanics and Materials, 2012, 233: 114–118.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51275102) supported by the National Natural Science Foundation of China; Project(159070220011) supported by the Science and Technology Innovative Research Programs Foundation of Harbin city, China; Project(HEUCF110702) supported by the Fundamental Research Funds for the Central Universities of China

Rights and permissions

About this article

Cite this article

Gu, Yq., Zhao, G., Liu, H. et al. Characteristics of seal shell body’s rubber ring with bionic dimpled surfaces of aerodynamic extinguishing cannon. J. Cent. South Univ. 20, 3065–3076 (2013). https://doi.org/10.1007/s11771-013-1830-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-013-1830-2