Abstract

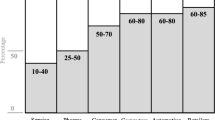

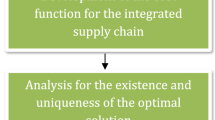

A replenishment decision-making model for supply-hub is firstly established from the angle of supplier, and optimal replenishment decision of the supplier is analyzed. Then, inventory optimization model for supply-hub is formulated from the angle of the manufacturer, and the optimization algorithm for obtaining optimal inventory levels is given. The result shows that liability period decides the share of the inventory cost between two sides in supply chain. With the increase of liability period, the service level has been quickly reduced even though the manufacturer’s cost has been cut down by transferring the inventory cost to the supplier. As to the safety inventory, if the lower bound of components safety inventory increases, the supplier’s cost will rise up more slowly than the liability period does, while the service levels increases as the safety inventory’s lower bound is raised.

Similar content being viewed by others

References

BARNES E, DAI J, DENG S, DOWN D, GOH M, CHUIN L H. On the strategy of supply hubs for cost reduction and responsiveness [R]. The Logistics Institute-Asia Pacific Report, Georgia Institute of Technology and National University of Singapore, 2000.

QETINKAYA S, LEE C Y. Stock replenishment and shipment scheduling for vendor-manage inventory systems [J]. Management Science, 2000, 46(2): 217–232.

DISNEY S M, TOWILL D R. The effect of vendor managed inventory (VMI) dynamics on bullwhip effect in supply chains [J]. International Journal of Production Economics, 2003, 85(2): 199–215.

SONG J S, YANO C A, LERSSRISURIYA P. Contract assembly: Dealing with combined supply lead time and demand quantity uncertainty [J]. Manufacturing & Service Operations Management, 2000(2): 287–296.

GULER M G, BILGI T. On coordinating an assembly system under random yield and random demand [J]. European Journal of Operational Research, 2009, 196(1): 342–350.

YANO C A, LEE H L. Lot sizing with random yields: A review [J]. Operations Research, 1995(43): 331–334.

GERCHAK Y, WANG Y, YANO C A. Lot sizing in assembly systems with random component yields [J]. IIE Transactions, 1994, 26(2): 19–24.

TANG O, GRUBBSTROM R W. The detailed coordination problem in a two-level assembly system with stochastic leadtimes [J]. International Journal of Production Economics, 2003, 81/82: 415–429.

YANO C A. Stochastic leadtimes in two-level assembly systems [J]. IIE Transactions, 1987, 19(4): 371–378.

GURNANI H, AKELLA R, LEHOCZKY J. Optimal order policies in assembly systems with random demand and random supplier delivery [J]. IIE Transactions, 1996(28): 865–878.

GURNANI H, GERCHAK Y. Coordination in decentralized assembly systems with uncertain component yields [J]. European Journal of Operational Research, 2007(3): 1559–1576.

KWON H D, LIPPMAN S A, MCCARDLE K, TANG C S. Managing time-based contracts with delayed payments [D]. Los Angles, USA: UCLA Anderson School, 2008.

IYER A V, BERGEN M E. Quick response in manufacturer-retailer channels [J]. Management Science, 1997, 43(4): 559–570.

GROUT J R, CHRISTY D P. A model of incentive contracts for just-in-time delivery [J]. European Journal of Operational Research, 1996(96): 139–147.

GUI_RIDA A L, NAGI R. Cost characterizations of supply chain delivery performance [J]. International Journal of Production Economics, 2006, 102(1): 22–36.

GROUT J R. Influencing a supplier using delivery windows: Its effect on the variance of flow time and on-time delivery [J]. Decision Science, 1998, 29(3): 747–764.

DISNEY S M, TOWILL D R. The effect of vendor managed inventory (VMI) dynamics on the bullwhip effect in supply chains [J]. International Journal of Production Economics, 2003, 85(2): 199–215.

RUNGTUSANATHAM M, RABINOVICH E, ASHENBAUM B, WALLIN C. Vendor-owned inventory management arrangements in retail: An agency theory perspective [J]. Journal of Business Logistics, 2007, 28(1): 111–135.

LEE C, CHU W. Who should control inventory in a supply chain? [J]. European Journal of Operational Research, 2005, 164(1): 158–172.

DONG X, XU K. A supply chain model of vendor managed inventory [J]. Transportation Research Part E: Logistics and Transportation Review, 2002, 38(2): 75–95.

RU J, WANG Y Z. Consignment contracting: Who should control inventory in the supply chain? [J]. European Journal of Operational Research, 2010, 201(3): 760–769.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(71102174, 70971036) supported by the National Natural Science Foundation of China; Project(9123028) supported by the Beijing Natural Science Foundation, China; Project(20111101120019) supported by the Specialized Research Fund for Doctoral Program of Higher Education of China; Project(11JGC106) supported by the Beijing Philosophy & Social Science Foundation of China; Projects (NCET-10-0048, NCET-10-0043) supported by the Program for New Century Excellent Talents in Universities of China; Project (2010YC1307) supported by the Excellent Young Teacher in Beijing Institute of Technology of China

Rights and permissions

About this article

Cite this article

Li, G., Huang, K., Yao, Q. et al. Replenishment policy and inventory optimization for supply-hub with liability period consideration. J. Cent. South Univ. 20, 2914–2921 (2013). https://doi.org/10.1007/s11771-013-1813-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-013-1813-3