Abstract

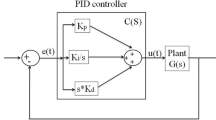

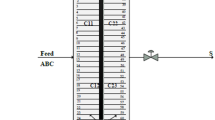

The control design, based on self-adaptive PID with genetic algorithms (GA) tuning on-line was investigated, for the temperature control of industrial microwave drying rotary device with the multi-layer (IMDRDWM) and with multivariable nonlinear interaction of microwave and materials. The conventional PID control strategy incorporated with optimization GA was put forward to maintain the optimum drying temperature in order to keep the moisture content below 1%, whose adaptation ability included the cost function of optimization GA according to the output change. Simulations on five different industrial process models and practical temperature process control system for selenium-enriched slag drying intensively by using IMDRDWM were carried out systematically, indicating the reliability and effectiveness of control design. The parameters of proposed control design are all on-line implemented without iterative predictive calculations, and the closed-loop system stability is guaranteed, which makes the developed scheme simpler in its synthesis and application, providing the practical guidelines for the control implementation and the parameter design.

Similar content being viewed by others

References

MOTEVALI A, MINAEI S, KHOSHTAGAZA M H. Evaluation of energy consumption in different drying methods [J]. Energy Conversion and Management, 2011, 52(2): 1192–1199.

YAGMUR E, SIMSEK E H, AKTAS Z, TOGRUL T. Effect of CuO receptor on the liquid yield and composition of oils derived from liquefaction of coals by microwave energy [J]. Energy Conversion and Management, 2008, 49(11): 3043–3050.

FITO P, CHIRALT A. The use of water-structure-functionality ensemble in dried food product development [J]. Food Science and Technology International, 2003, 9(3): 151–156.

FITO P, CHIRALT A, BARAT J M, ANDRÉS A, MARTÍNEZ-MONZÓ J, MARTNEZ-NAVARRETE N. Vacuum impregnation for development of new dehydrated products [J]. Journal of Food Engineering. 2001, 49(4): 297–302.

AGUILERA J M, CHIRALT A, FITO P. Food dehydration and product structure [J]. Trends in Food Science & Technology, 2003, 14(10): 432–437.

AHRNE L M, PEREIRA N R, STAACK N, FLOBERG P. Microwave convective drying of plant foods at constant and variable microwave power [J]. Drying Technology, 2007, 25(7): 1149–1153.

YANG Xu, LIU Jun-jie, YANG Cun-zhi. Performance characteristics of microwave drying device and its market prospect analysis [J]. Journal of Agricultural Mechanization Research, 2007 (1): 41–42. (in Chinese)

PENG Jin-hui, YANG Xian-wan. The new applications of microwave power [M]. Yunnan: Yunnan Science & Technology Press, 1997: 32–100. (in Chinese)

NANTHAKUMAR B, PICKLES C A, KELEBEK S. Microwave pretreatment of a double refractory gold ore [J]. Minerals Engineering, 2007, 20(11): 1109–1119.

REQUENA-PÉREZ M E, PEDREÑO-MOLINA J L, MONZÓ-CABRERA J, DÍAZ-MORCILLO A. Multimode cavity efficiency optimization by optimum load location-Experimental approach [J]. IEEE Transactions on Microwave Theory and Techniques, 2005, 53(6): 2114–2120.

MONZÓ-CABRERA J, PEDREÑO-MOLINA J L, TOLEDO A. Feedback control procedure for energy efficiency optimization of microwave-heating ovens [J]. Measurement, 2009, 42(8): 1257–1262.

ALONSO A A, BANGA J R, PEREZ-MARTIN R. Modeling and adaptive control for batch sterilization [J]. Computers & Chemical Engineering, 1998, 22(3): 445–458.

HOLLAND J H. Adaptation in natural and artificial systems: An introductory analysis with application to biology, control and artificial intelligence [M]. Michigan, Ann Arbor, MIT: University of Michigan Press, 1975.

GOSSELIN L, TYE-GINGRAS M, MATHIEU-POTVIN F. Review of utilization of genetic algorithms in heat transfer problems [J]. International Journal of Heat and Mass Transfer, 2009, 52(9): 2169–2188.

FRIEDRICH M, PERNE R. Design and control of batch reactors-An industrial viewpoint [J]. Computers & Chemical Engineering, 1995, 19(11): 357–368.

ALTINTEN A, ERDOGAN S, HAPOGLU H, ALIEV F. ALPBAZ M. Application of fuzzy control method with genetic algorithm to a polymerization reactor at constant set point [J]. Chemical Engineering Research Design, 2006, 84(A11): 1012–1018.

ALTINTEN A, KETEVANLIOĞLU F, ERDOĞAN S, HAPOĞLU H F, ALPBAZ M. Self-tuning PID control of jacketed batch polystyrene reactor using genetic algorithm [J]. Chemical Engineering Journal, 2008, 138(1/2/3): 490–497.

ASTRÖM K J, HÄGGLUND T. Revisiting the Ziegler-Nichols step response method for PID control [J]. Journal of Process Control, 2004, 14(6): 635–650.

ASTRÖM K J, HÄGGLUND T. The future of PID control [J]. Control Engineering Practice, 2001, 9(11): 1163–1175.

YANG Zhi, CHEN Zhi-tang, FAN Zheng-ping, LI Xiao-dong. Tuning of PID controller based on improved particle-swarm-optimization [J]. Control Theory & Applications, 2010, 27(10): 1345–1352. (in Chinese)

CLARKE D W, MOHTADI C, TUFFS P S. Generalized predictive control-Part I: The basic algorithm [J]. Automatic, 1987, 23(2): 137–148.

LIANG Gui-an, PENG Jin-hui, BAI Song, ZHANG Shi-min, LI Jun, GUO Sheng-hui, LI Xin-pei, LIANG Wei. Research on control system of microwave pretreatment of selenium rich slag [J]. Journal of Kunming University of Science and Technology: Natural Science Edition, 2011, 36(2): 16–19. (in Chinese)

LIU Bing-guo, PENG Jin-hui, ZHANG Li-bo, SRINIVASAKANNAN C, HUANG Min, ZHANG Ze-biao, GUO Sheng-hui. Microwave absorbing characteristics and temperature increasing behavior of basic cobalt carbonate in microwave field [J]. Journal of Central South University of Technology, 2010, 17(6): 1211–1215.

YANG Biao, LI Wei, PENG Jin-hui, GUO Sheng-hui, ZHANG Shi-min. Microwave energy heating process for cycling fluid medium based APSO-PID control strategy [C]//2nd International Conference on Advances in Energy Engineering (ICAEE). Bangkok, 2012: 601–607.

LI Ying-wei, PENG Jin-hui, LIANG Gui-an, LI Wei, ZHANG Shi-min. Optimization of processing parameters for microwave drying of selenium-rich slag using incremental improved back-propagation neural network and response surface methodology [J]. Journal of Central South University of Technology, 2011, 18(5): 1441–144.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51090385) supported by the Major Program of National Natural Science Foundation of China; Project(2011IB001) supported by Yunnan Provincial Science and Technology Program, China; Project(2012DFA70570) supported by the International Science & Technology Cooperation Program of China; Project(2011IA004) supported by the Yunnan Provincial International Cooperative Program, China

Rights and permissions

About this article

Cite this article

Yang, B., Liang, Ga., Peng, Jh. et al. Self-adaptive PID controller of microwave drying rotary device tuning on-line by genetic algorithms. J. Cent. South Univ. 20, 2685–2692 (2013). https://doi.org/10.1007/s11771-013-1784-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-013-1784-4