Abstract

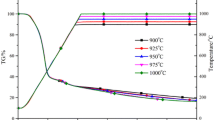

Thermogravimetric study of rubber compositions (operating glove and catheter) in medical waste was carried out using the thermogravimetric analyser (TGA), at the heating rate of 20 °C/min in a stream of N2. The results indicate that the decomposition process of operating glove appears an obvious mass loss stage at 250–485 °C, while catheter has two obvious stages at 240–510 °C and 655–800 °C, respectively; both samples present endothermic pyrolysis reaction; the decomposition of operating glove and the first mass loss stage of catheter are in agreement with natural rubber pyrolysis; the second mass loss stage of catheter corresponds to CaCO3 decomposition. Based on the experimental results, a novel two-step four-reaction model was established to simulate the whole continuous processes, which could more satisfactorily describe and predict the pyrolysis processes of rubber compositions, being more mechanistic and conveniently serving for the engineering.

Similar content being viewed by others

References

YAN J H, ZHU H M, JIANG X G, CHI Y, CEN K F. Analysis of volatile species kinetics during typical medical waste materials pyrolysis using a distributed activation energy model [J]. Journal of Hazardous Materials, 2009, 162(2/3): 646–651.

AHMED I, GUPTA A K. Characteristic of hydrogen and syngas evolution from gasification and pyrolysis of rubber [J]. International Journal of Hydrogen Energy, 2011, 36(7): 4340–4347.

DENG N, ZHANG Y F, WANG Y. Thermogravimetric analysis and kinetic study on pyrolysis of representative medical waste composition [J]. Waste Management, 2008, 28(9): 1572–1580.

ZHAN Z H, QIU K Q. Pyrolysis kinetics and TG-FTIR analysis of waste epoxy printed circuit boards [J]. Journal of Central South University of Technology, 2011, 18(2): 331–336.

LUO S Y, XIAO B, HU Z Q, LIU S M, GUAN Y W, CAI L. Influence of particle size on pyrolysis and gasification performance of municipal solid waste in a fixed bed reactor [J]. Bioresource Technology, 2010, 101(16): 6517–6520.

KAMINSKY W, MENNERICH C, ZHANG Z. Feedstock recycling of synthetic and natural rubber by pyrolysis in a fluidized bed [J]. Journal of Analytical and Applied Pyrolysis, 2009, 85(1/2): 334–337.

RIYAJIAN S A, INTHARIT I, TANGBORIBOONRAT P. Physical properties of polymer composite: Natural rubber glove waste/polystyrene foam waste/cellulose [J]. Industrial Crops and Products, 2012, 36(1): 376–382.

QUEK A, BALASUBRAMANIAN R. Mathematical modeling of rubber tire pyrolysis [J]. Journal of Analytical and Applied Pyrolysis, 2012, 95(1): 1–13.

SEIDELT S, MULLER H M, BOCKHON H. Description of tire pyrolysis by thermal degradation behavior of main components [J]. Journal of Analytical and Applied Pyrolysis, 2006, 75(1): 11–18.

CHEN F Z, QIAN J L. Studies of the thermal degradation of waste rubber [J]. Waste Management, 2003, 23(6): 463–467.

CHEUNG K Y, LEE K L, LAM K L. Operation strategy for multi-stage pyrolysis [J]. Journal of Analytical and Applied Pyrolysis, 2011, 91(1): 165–182.

XIE Zhong-lin, YANG Min-fang. Practical formula of rubber products [M]. Beijing: Chemical Industry Press, 1999: 645. (in Chinese)

GARCIA A N, MARCILLA A, FONT R. Thermogravimetric kinetic study of the pyrolysis of municipal solid waste [J]. Thermochimica Acta, 1995, 254(15): 277–304.

DOLLIMORE D, TONG P, ALEXANDER K S. The kinetic interpretation of the decomposition of calcium carbonate by use of relationships other than the Arrhenius equation [J]. Thermochimica Acta, 1996, 282-283(10): 13–27.

HOU Gui-hua, CHEN Xiao-dong, XU Zhong-zi. Effect of copper oxide on decomposition kinetics for china calcium carbonate [J]. Journal of the Chinese Ceramic Society, 2005, 33(1): 109–114. (in Chinese)

ZHAO Wei, WANG Qi, Zou Zong-shu, LIU Xiao-qing, ZHANG Hong-xia. Pyrolysis mechanism and kinetics of plasticand rubber waste [J]. Journal of Engineering Thermophysics, 2008, 29(11): 1977–1979. (in Chinese)

QUEK A, BALASUBRAMANIAN R. An algorithm for the kinetics of tire pyrolysisunder different heating rates [J]. Journal of Hazardous Materials, 2009, 166(1): 126–132.

HU Li-fen, ZHONG Ya-jun. Kinetic analysis of catalytic thermal decomposition of rubber [J]. Chemical Industry and Engineering Progress, 2008, 27(6): 925–927. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(50378062) supported by the National Natural Science Foundation of China; Project(09JCYBJC08100) supported by the Natural Science Foundation of Tianjin Municipality, China; Project supported by Key Laboratory Program of the Ministry of Education, China

Rights and permissions

About this article

Cite this article

Deng, N., Wang, Ww., Chen, Gw. et al. Pyrolysis characteristics of rubber compositions in medical waste. J. Cent. South Univ. 20, 2466–2471 (2013). https://doi.org/10.1007/s11771-013-1758-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-013-1758-6