Abstract

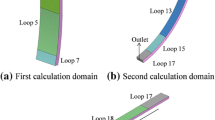

A three-dimensional finite-element model of slab continuous casting mold was conducted to clarify the effect of cooling structure on thermal behavior of copper plates. The results show that temperature distribution of hot surface is mainly governed by cooling structure and heat-transfer conditions. For hot surface centricity, maximum surface temperature promotions are 30 °C and 15 °C with thickness increments of copper plates of 5 mm and nickel layers of 1 mm, respectively. The surface temperature without nickel layers is depressed by 10 °C when the depth increment of water slots is 2 mm and that with nickel layers adjacent to and away from mold outlet is depressed by 7 °C and 5 °C, respectively. The specific trend of temperature distribution of transverse sections of copper plates is nearly free of cooling structure, but temperature is changed and its law is similar to the corresponding surface temperature.

Similar content being viewed by others

References

YU Hai-liang, LIU Xiang-hua. Longitudinal crack on slab surface at straightening stage during continuous casting using finite element method [J]. Journal of Central South University of Technology, 2010, 17(2): 235–238.

ZHOU Shu-cai, BAI Chen-guang, LEI Ya, REN Zheng-de, CAO Peng-jun, YANG Zhi-li. Effect of low-frequency rotary electromagnetic-field on solidification structure of continuous casting austenitic stainless steel [J]. Journal of Central South University of Technology, 2009, 16(3): 360–364.

O’CONNOR T G, DANTZIG J A. Modeling the thin-slab continuous-casting mold [J]. Metallurgical and Materials Transactions B, 1994, 25(3): 443–457.

PARK J K, THOMAS B G, SAMARASEKERA I V, YOON U S. Thermal and mechanical behavior of copper molds during thin-slab casting (I): Plant trial and mathematical modeling [J]. Metallurgical and Materials Transactions B, 2002, 33(3): 425–436.

PARK J K, THOMAS B G, SAMARASEKERA I V, YOON U S. Thermal and mechanical behavior of copper molds during thin-slab casting (II): Mold crack formation [J]. Metallurgical and Materials Transactions B, 2002, 33(3): 437–449.

THOMAS B G. Modeling of the continuous casting of steel: Past, present, and future [J]. Metallurgical and Materials Transactions B, 2002, 33(6): 795–812.

KORIC S, HIBBELER L C, THOMAS B G. Explicit coupled thermo-mechanical finite element model of steel solidification [J]. International Journal for Numerical Methods in Engineering, 2009, 78(1): 1–31.

KORIC S, THOMAS B G. Thermo-mechanical models of steel solidification based on two elastic visco-plastic constitutive laws [J]. Journal of Materials Processing Technology, 2008, 197(1/2/3): 408–418.

LIU X D, ZHU M Y. Finite element analysis of thermal and mechanical behavior in a slab continuous casting mold [J]. ISIJ International, 2006, 46(11): 1652–1659.

SANTILLANA B, HIBBELER L C, THOMAS B G, HAMOEN A, KAMPERMAN A, KNOOP W V D. Heat transfer in funnel-mould casting: Effect of plate thickness [J]. ISIJ International, 2008, 48(10): 1380–1388.

MENG X N, ZHU M Y. Thermal behavior of hot copper plates for slab continuous casting mold with high casting speed [J]. ISIJ International, 2009, 49(9): 1356–1361.

NAKADA H, SUSA M, SEKO Y, HAYASHI M, NAGATA K. Mechanism of heat transfer reduction by crystallization of mold flux for continuous casting [J]. ISIJ International, 2008, 48(4): 446–453.

HANAO M, KAWAMOTO M. Flux film in the mold of high speed continuous casting [J]. ISIJ International, 2008, 48(2): 180–185.

SARASWAT R, MAIJER D M, LEE P D, MILLS K C. The effect of mould flux properties on thermo-mechanical behaviour during billet continuous casting [J]. ISIJ International, 2007, 47(1): 95–104.

SAVAGE J, PRITCHARD W H. The problem of rupture of the billet in the continuous casting of steel [J]. Journal of the Iron and Steel Institute, 1954, 178(11): 269–277.

SHAMSI M R R I, AJMANI S K. Three dimensional turbulent fluid flow and heat transfer mathematical model for the analysis of a continuous slab caster [J]. ISIJ International, 2007, 47(3): 433–442.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51004031) supported by the National Natural Science Foundation of China; Project(50925415) supported by the National Outstanding Young Scientist Foundation of China; Project(20100042120012) supported by the Special Research Fund for Doctoral Programs of Ministry of Education of China; Project(N090402022) supported by the Fundamental Research Funds for the Central Universities of China

Rights and permissions

About this article

Cite this article

Meng, Xn., Zhu, My. Effect of cooling structure on thermal behavior of copper plates of slab continuous casting mold. J. Cent. South Univ. 20, 318–325 (2013). https://doi.org/10.1007/s11771-013-1490-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-013-1490-2