Abstract

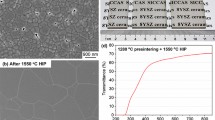

The 8% (mass fraction) yttrium-partially-stabilized zirconia (8YSZ) ceramic was fabricated via liquid phase sintering at 1 200–1 400 °C by adding different mass ratios of CuO-16.7%TiO2 (molar fraction) as sintering aid. Relative density, microstructure, Vickers hardness and bending strength as a function of sintering temperature and additive content were investigated. The experiment results show that liquid phase sintering at low temperature can be realized through adding CuO-16.7% TiO2 to 8YSZ. The Vickers hardness and bending strength of samples with sintering aid are generally much higher than those of samples without sintering aid for all sintering temperatures, and increase with the increase of sintering temperature. When the addition content of CuO-16.7% TiO2 is beyond 0.5%, the relative density, Vickers hardness and bending strength decrease with the increase of the mass ratio of sintering aid. Low additions of sintering aid are beneficial to aiding densification; high additions of sintering aid are detrimental to the sintered properties mainly due to greater amounts of pores generated by the volatilization of oxygen with the eutectic reaction between copper oxide and titanium dioxide. It is found that the fine grain size and high relative density are two main reasons of the high bending strength and Vickers hardness of the materials.

Similar content being viewed by others

References

CLARKE D R, LEVI C G. Materials design for the next generation thermal barrier coatings [J]. Annual Review of Materials Research, 2003, 33: 383–417.

PADTURE N P, GELL M, JORDAN E H. Thermal barrier coatings for gas turbine engine applications [J]. Science, 2002, 296(5566): 280–284.

CHOY K L. Chemical vapour deposition of coatings [J]. Progress in Materials Science, 2003, 48: 57–170.

BOONE D H. Physical vapor deposition processes [J]. Materials Science and Technology, 1986, 2(3): 220–224.

WANG X, LAN W H, XIAO P. Fabrication of yttria stabilized zirconia coatings by a novel slurry method [J]. Thin Solid Films, 2006, 494: 263–267.

JI C, LAN W H, XIAO P. Fabrication of yttria-stabilized-zirconia coatings using electrophoretic deposition: packing mechanism during deposition [J]. Journal of American Ceramic Society, 2008, 91(4): 1102–1110.

CORNI I, RYAN M. P, BOCCACCINI A R. Electrophoretic deposition: From traditional ceramics to nanotechnology [J]. Journal of the European Ceramic Society, 2008, 28(7): 1353–1367.

JI C Z, SHAPIRO I P, XIAO P. Fabrication of yttria-stabilized-zirconia coatings using electrophoretic deposition: Effects of agglomerate size distribution on particle packing [J]. Journal of the European Ceramic Society, 2009, 29: 3167–3175.

LAN W H, XIAO P. Fabrication of yttria-stabilized-zirconia thick coatings via slurry process with pressure infiltration [J]. Journal of the European Ceramic Society, 2009, 29: 391–401.

BOUTZ M M R, WINNUBST A J A, HARTGERS F, BURGGRAAF A J. Effect of additives on densification and deformation of tetragonal zirconia [J]. Journal of Materials Science, 1994, 29: 5374–5382.

LAWSON S, GILL C. DRANSFIELD G P. The effects of copper and iron oxide additions on the sintering and properties of Y-TZP [J]. Journal of Materials Science, 1995, 30: 3057–3060.

VERKERK M J, WINNUBST A J A, BURGGRAAF A J. Effect of impurities on sintering and conductivity of yttria-stabilized zirconia [J]. Journal of Materials Science, 1982, 17: 3113–3122.

KEIZER K, BURGGRAAF A J, DE G W. The effect of Bi2O3 on the electrical and mechanical properties of ZrO2-Y2O3 ceramics [J]. Journal of Materials Science, 1982, 17: 1095–1102.

BUCHANAN R C, SIRCAR A. Densification of calcia-stabilized zirconia with borates [J]. Journal of American Ceramic Society, 1983, 66(2): C20–C21.

SUN Y, ZHANG Y, GUO J. Microstructure and bending strength of 3Y-TZP ceramics by liquid-phase sintering with CAS addition [J]. Ceramics International, 2003, 29: 229–232.

ERKALFA H, MISIRLI Z, BAYKARA T. Densification of alumina at 1 250 °C with MnO2 and TiO2 additives [J]. Ceramics International, 1995, 21: 345–348.

HUANG X W, WANG S W, ZHAO S K, HUANG X X. Effect of liquid-forming additives on the sintering and mechanical properties of Al2O3/3Y-TZP (30 vol. %) composite [J]. Materials Research Bulletin, 2002, 37(10): 1709–1719.

RAMESH S, GILL C, LAWSON S. The effect of copper oxide on sintering, microstructure, mechanical properties and hydrothermal ageing of coated 2.5Y-TZP ceramics [J]. Journal of Materials Science, 1999, 34: 5457–5467.

HUANG X W, WANG S W, HUANG X X. Influence of sintering aids on sintering and mechanical properties of 3Y-TZP/Al2O3 (40 vol. %) composite [J]. Journal of Materials Science Letters, 2002, 21: 1439–1443.

ZHANG Bin, WANG Huan-ping, MA Hong-ping, XU Shi-qing, LI Deng-hao, ZHOU Guang-miao. Mechanism of lowering the sintering temperature of Al2O3 ceramic by the addition of CuO-TiO2 (I) [J]. Chinese Journal of Materials Research, 2009, 5: 534–540. (in Chinese)

LU F H, FANG F X, CHEN Y S. Eutectic reaction between copper oxide and titanium dioxide [J]. Journal of the European Ceramic Society, 2001, 21: 1093–1099.

KINGERY W D. Ceramic fabrication processes [M]. New York: Technology Press of Massachusetts Institute of Technology and John Wiley and Sons, Inc, 1958: 131–143.

LU H Y, CHEN S Y. Sintering and compensation effect of donor- and acceptor-codoped 3mol% Y2O3-ZrO2 [J]. Journal of Materials Science, 1992, 27: 4791–4796.

MECARTNEY M L. Influence of an amorphous second phase on the properties of yttria-stabilized tetragonal zirconia polycrystals (Y-TZP) [J]. Journal of American Ceramic Society, 1987, 70(1): 54–58.

RAMESH S, MEENALOSHINE S, TAN C Y, KELCIN C W J, TENG W D. Effect of manganese oxide on the sintered properties and low temperature degradation of Y-TZP ceramics [J]. Ceramics International, 2008, 34(7): 1603–1608.

ZHOU Yu, JIA De-chang, WEN Guang-wu. Science of ceramics [M]. Harbin: Harbin Institute of Technology Press, 1999: 22–35. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(200805331062) supported by the Research Fund for the Doctoral Program of Higher Education of China; Project(2010FJ4061) supported by the Science and Technology Program of Hunan Province, China

Rights and permissions

About this article

Cite this article

Zhou, Hm., Guo, Yj., Li, J. et al. Microstructure and mechanical properties of 8YSZ ceramics by liquid-phase sintering with CuO-TiO2 addition. J. Cent. South Univ. Technol. 19, 1196–1201 (2012). https://doi.org/10.1007/s11771-012-1128-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-012-1128-9