Abstract

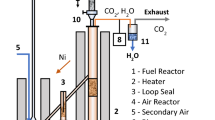

For acquiring the details in aluminum holding furnace with bottom porous brick purging system, efforts were performed to try to find out the potential optimal operation schemes. By adopting transient analysis scheme and constant boundary temperature, combustion in the furnace was investigated numerically using computational fluid dynamics (CFD). The predicted gas temperature shows good agreement with the measured results, and the predicted energy distribution of the furnace is consistent with that obtained from energy balance experiment, which confirms the reliability of the numerical solution. The results show that as the fuel-air mixture temperature rises up from 300 K to 500 K, the energy utilization of the furnace could increase from 34.55% to 37.14%. However, as the excess air coefficient increases from 1.0 to 1.4, energy utilization drops from 34.55% to 29.56%. Increasing the combustion temperature is the most effective way to improve the energy efficiency of the furnace. High reactant temperature and medium excess air coefficient are recommended for high operation performance, and keeping the furnace jamb sealed well for avoiding leakage has to be emphasized.

Similar content being viewed by others

References

PRILLHOFER B, ANTREKOWITSCH H, BOTTCHER H. Optimisation of the melt quality in casting/holding furnaces [C]// DEYOUND D H. Light Metals 2008. Warrendale: TMS, 2008: 627–632.

MIGCHIELSIN I J, HANS-WALTER-GRAB D I, SCHMIDT T. Design considerations for holding and casting furnaces [C]// DEYOUND D H. Light Metals 2008. Warrendale: TMS, 2008: 593–596.

GAMWEGER K, BAUER P. Energy savings and productivity increases at an aluminum slug plant due to bottom gas purging [C]// NEELAMEGGHAM N R, REDDY R G., BELT C K, VIDAL E E. Energy Technology Perspectives. Warrendale: TMS, 2009: 169–171.

LARSEN D A. Degassing aluminum using static fine-pore refractory diffusers [J]. JOM, 2007, 49(8): 27–28.

BUI R T, PERRON J. Performance analysis of the aluminum casting furnace [J]. Metall Trans B, 1987, 19(2): 171–180.

OUTLLET R, BUI R T, PERRON J. Numerical simulation of a casting furnace [J]. Simulation, 1990, 54(2): 92–100.

BUI R T, PERRON J. Optimal control of an aluminum casting furnace: Part I. The control model [J]. Metall Trans B, 1990, 21(3): 487–494.

BUI R T, PERRON J. Optimal control of an aluminum casting furnace: Part II. Fuel optimization [J]. Metall Trans B, 1990, 21(3): 495–500.

BOURGEOIS T, BUI R T, CHARETTE A, KOCAEFE Y S. Mathematical modeling of an aluminum casting furnace combustion chamber [J]. Metall Trans B, 1989, 20(3): 421–429.

NIECKELE A O, NACCACHE M F, GOMES M S P. Numerical modeling of an industrial aluminum melting furnace [J]. J Energy Resour Technol, 2004, 126(1): 72–81.

BOKE Y E, AYDIN O. Effect of the radiation surface on temperature and NOx emission in a gas fired furnace [J]. Fuel, 2009, 88(10): 1878–1884.

KONTOGEORGOS D A, KERAMIDA E P, FOUNTI M A. Assessment of simplified thermal radiation models for engineering calculations in natural gas-fired furnace [J]. Int J Heat Mass Trans, 2007, 50(25/26): 5260–5268.

ZHOU N J, ZHOU S H, ZHANG J Q, PAN Q L. Numerical simulation of aluminum holding furnace with fluid-solid coupled heat transfer [J]. Journal of Central South University of Technology, 2010, 17(6): 1389–1394.

STEFANIDIS G D, MERCI B, HEYNDERICKX G J, MARIN G B. CFD simulations of steam cracking furnaces using detailed combustion mechanisms [J]. Comput Chem Eng, 2006, 30(4): 635–649.

GB/T 2587-2009, General principles for energy balance of equipment using energy [S]. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2009GK2009) supported by the Science and Technology Program of Hunan Province, China

Rights and permissions

About this article

Cite this article

Zhang, Jq., Zhou, Nj. & Zhou, Sh. Combustion and energy balance of aluminum holding furnace with bottom porous brick purging system. J. Cent. South Univ. Technol. 19, 200–205 (2012). https://doi.org/10.1007/s11771-012-0992-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-012-0992-7