Abstract

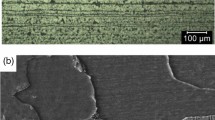

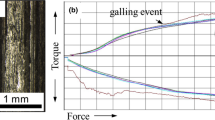

In order to obtain a high-performance surface on P110 steel that can meet the requirements in oil/gas field environment, the chromium coatings were fabricated by pack cementation. The chromium coatings differed in with/without the addition of La2O3. Scanning electron microscope (SEM), energy dispersive X-ray spectrometer (EDS), X-ray diffractometer (XRD) and microhardness tester were employed to investigate the surface morphologies, surface element distributions, microstructures, phase constitutions and microhardness of the coatings. Friction-wear tests of the P110 steel substrate and the coatings were conducted in air at ambient temperature and humidity. The results show that uniform and continuous coatings are formed on P110 steel regardless of adding La2O3 or not. The chromium coatings consist of Cr23C6, Cr7C3, and (Cr, Fe)7C3. The La2O3-added chromium coating is more beneficial in terms of surface morphology, microstructure, thickness and microhardness as compared with the coating without adding La2O3. Chromizing treatment significantly improves the surface hardness and wear resistance of the P110 steel. The wear resistance of the tested samples can be sorted in the following sequence: La2O3-coating>no RE-coating>bare P110 steel.

Similar content being viewed by others

References

LI He-lin, ZHANG Ya-ping, HAN Li-hong. Development situation of OCTG and production localization of Hi-grade OCTG: Part ? [J]. Steel Pipe, 2007, 36(6): 1–6. (in Chinese)

WU Xue-feng, LIN Yuan-hua, WU Cai-wen, SHI Tai-he, LI Run-fang, LIN Teng-jiao. Research development of the preventing wear measures of casing [J]. Journal of Southwest Petroleum Institute, 2004, 26(4): 65–70. (in Chinese)

LIN Yuan-hua, FU Jian-hong, SHI Tai-he, YAN Ren-jun, HE Zhi-gang, DONG Wei, LI Run-fang. Research on casing wear mechanism and antiwear measures [J]. Natural Gas Industry, 2004, 7: 58–61. (in Chinese)

CAO Xiao-ming, WEN Ming, DU An. Modern metal surface alloying technologies [M]. Beijing: Chemical Industrial Press, 2007: 1–2. (in Chinese)

LI He-lin, ZHANG Ya-ping, HAN Li-hong. Development situation of OCTG and production localization of Hi-grade OCTG: PartII [J]. Steel Pipe, 2008, 37(1): 1–6. (in Chinese)

ZHOU Y B, CHEN H, ZHANG H, WANG Y. Preparation and oxidation of an Y2O3-dispersed chromizing coating by pack cementation at 800 °C [J]. Vacuum, 2008, 82: 748–753.

LEE S B, CHO K H, LEE W G, JANG H. Improved corrosion resistance and interfacial contact resistance of 316L stainless-steel for proton exchange membrane fuel cell bipolar plates by chromizing surface treatment [J]. Journal of Power Sources, 2009, 187: 318–323.

WANG Z B, LU J, LU K. Wear and corrosion properties of a low carbon steel processed by means of SMAT followed by lower temperature chromizing treatment [J]. Surface and Coatings Technology, 2006, 201: 2796–2801.

VOURLIAS G, PISTOFIDIS N, CHALIAMPALIAS D, PAVLIDOU E, STERGIOUDIS G, POLYCHRONIADIS E K, TSIPAS D. Zinc deposition with pack cementation on low carbon steel substrates [J]. Journal of Alloys and Compounds, 2006, 416: 125–130.

PENG X M, XIA C Q, LIU Y Y, WANG J H. Surface molybdenizing on titanium by halide-activated pack cementation [J]. Surface and Coatings Technology, 2009, 203: 3306–3310.

HOUNGNINOU C, CHEVALIER S, LARPIN J P. Synthesis and characterization of pack cemented aluminide coatings on metals [J]. Applied Surface Science, 2004, 236: 256–269.

TSIPAS S A, OMAR H, PEREZ F H, TSIPAS D N. Boroaluminide coatings on ferritic-martensitic steel deposited by low-temperature pack cementation [J]. Surface and Coatings Technology, 2008, 202: 3263–3271.

ZHANG Jin-zhu, YANG Zong-lun, WEI Ke-yuan. Study of the catalysis and diffusion mechanism by rare earth (RE) elements during the thermo-chemical treatment [J]. Materials Review, 2006, 20(5): 223–225. (in Chinese)

SHARMA S P, DWIVEDI D K, JAIN P K. Effect of La2O3 addition on the microstructure, hardness and abrasive wear behavior of flame sprayed Ni based coatings [J].Wear, 2009, 267: 853–859.

JI Ze-sheng. Effect of rare earth on B-Al permeating and computer kinetic simulation of permeation layer forming [J]. Transactions of Nonferrous Metals Society of China, 1999, 9(4): 791–795.

HUANG Na-can, HU She-jun. Rare earth thermo-chemical treatment and rare earth material surface modification [J]. Chinese Rare Earths, 2003, 24(3): 59–63. (in Chinese)

QI Tao, GUO Xi-ping. Structure formation of Si-Y2O3 co-deposition coatings on Nb-silicide-based alloy [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(10): 1822–1828. (in Chinese)

ZHANG Xiao-hua, LIU Dao-xin. Effect of TiN/Ti multilayer on fretting fatigue resistance of Ti-811 alloy at elevated temperature [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(3): 557–562.

ZHAO Guo-gang, ZHOU Yue-bo, ZHANG Hai-jun. Sliding wear behaviors of electrodeposited Ni composite coatings containing micrometer and nanometer Cr particles [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(2): 319–323.

SUCHANEK J, KUKLIK V. Influence of heat and thermochemical treatment on abrasion resistance of structural and tool steels [J]. Wear, 2009, 267: 2100–2108.

YANG Jian-qun, LIU Yong, YE Zhu-yu, YANG De-zhuang, HE Shi-yu. Microstructure and tribological characteristics of nitrided layer on 2Cr13 steel in air and Vacuum [J]. Surface and Coatings Technology, 2009, 204: 705–712.

JIANG Jin-long, DAI Jian-feng, YANG Hua, WANG Qing. Wear behavior of Cu matrix composites reinforced with mixture of carbon and carbon nanotubes [J]. Journal of Wuhan University of Technology: Materials Science Edition, 2009, 24(2): 254–256.

JONES L C, LLEWELLYN R J. Sliding abrasion resistance assessment of metallic materials for elevated temperature mineral processing conditions [J]. Wear, 2009, 267: 2010–2017.

WAN Yi, XIONG Dang-sheng, LI Jian-liang. Cooperative effect of surface alloying and laser texturing on tribological performance of lubricated surfaces [J]. Journal of Central South University of Technology, 2010, 17(5): 906–910.

CHENG Jiang-bo, LIANG Xiu-bing, XU Bin-shi, WU Yi-xiong. Microstructure and wear behavior of FeBSiNbCr metallic glass coatings [J]. Journal of Materials Science and Technology, 2009, 25(5): 687–690.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2007CB607603) supported by the National Basic Research Program of China

Rights and permissions

About this article

Cite this article

Lin, Nm., Xie, Fq., Zhou, J. et al. Microstructures and wear resistance of chromium coatings on P110 steel fabricated by pack cementation. J. Cent. South Univ. Technol. 17, 1155–1162 (2010). https://doi.org/10.1007/s11771-010-0612-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-010-0612-3