Abstract

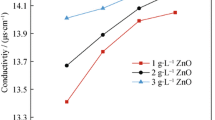

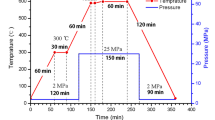

Microarc oxidation (MAO) coatings were prepared on 2024 aluminum alloy in a Na2SiO3-KOH electrolyte with KMnO4 addition varying from 0 to 4 g/L. The microstructure and phases of the coatings were characterized by scanning electron microscopy (SEM) and X-ray diffractometry (XRD), respectively. The corrosion resistance of MAO coatings was evaluated by electrochemical potentiodynamic polarization in 5% (mass fraction) NaCl solution. The results show that when KMnO4 is added into base electrolyte, the growth speed of oxide coatings is increased obviously. The main phase of oxide coatings is Al2O3, and the contents of MnO2 and Mn2AlO4 phases are increased at the top of oxide coatings with increasing the concentration of KMnO4. The solute elements participate in forming the oxide coatings. When a proper concentration of KMnO4 (2.5 g/L) is added into the base solution, the micropores of the MAO coatings are small and compact, and the corrosion resistance of oxide coatings is increased largely.

Similar content being viewed by others

References

XUE Wen-bin, SHI Xiu-ling, HUA Ming, LI Yong-liang. Preparation of anti-corrosion films by microarc oxidation on an Al-Si alloy [J]. Appl Surf Sci, 2007, 253: 6118–6124.

BUTYAGIN P I, KHOKHRYAKOV Y V, MAMAEV A I. Microplasma systems for creating coatings on aluminium alloys [J]. Mater Letts, 2003, 57: 1748–1751.

TIAN Jun, LUO Zhuang-zi, QI Shang-kui, SUN Xiao-jun. Structure and antiwear behavior of micro-arc oxidized coatings on aluminum alloy [J]. Surf Coat Technol, 2002, 154: 1–7.

CHEN Fei, ZHOU Hai, YAO Bin, QIN Zhen, ZHANG Qing-feng. Corrosion resistance property of the ceramic coating obtained through microarc oxidation on the AZ31 magnesium alloy surfaces [J]. Surf Coat Technol, 2007, 201: 4905–4908.

YEROKHIN A L, NIE X, LEYLAND A, MATTHEWS A, DOWEY S J. Plasma electrolysis for surface engineer [J]. Surf Coat Technol, 1999, 122: 73–93.

WU Han-hua, WANG Jian-bo, LONG Bei-yu, LONG Bei-long, JIN Zeng-sun, WANG Nai-dan, YU Feng-rong, BI Dong-mei. Ultra-hard ceramic coatings fabricated through microarc oxidation on aluminium alloy [J]. Appl Surf Sci, 2005, 252: 1545–1552.

SUNDARARAJAN G, RAMA KRISHNA L. Mechanisms underlying the formation of thick alumina coatings through the MAO coating technology [J]. Surf Coat Technol, 2003, 167: 269–277.

NIE X, MELETIS E I, JIANG J C, LEYLAND A, YEROKHIN A L, MATTHEWS A. Abrasive weary corrosion properties and TEM analysis of Al2O3 coatings fabricated using plasma electrolysis [J]. Surf Coat Technol, 2002, 149: 245–251.

XUE Wen-bin, DENG Zhi-wei, CHEN Ru-yi, ZHANG Tong-he, MA Hui. Microstructure and properties of ceramic coatings produced on 2024 aluminum alloy by microarc oxidation [J]. Journal of Materials Science, 2001, 36: 2615–2619.

GNEDENKOV S V, KHRISANFOVA O A, ZAVIDNAY A G, SINEBRUKHOV S L, KOVRYANOV A N, SCOROBOGATOVA T M, GORDIENKO P S. Production of hard and heat-resistant coatings on aluminium using a plasma micro-discharge [J]. Surf Coat Technol, 2000, 123: 24–28.

WANG Chang-zheng, ZHANG Dong, JIANG Yong-feng. Growth process and wear resistance for ceramic coatings formed on Al-Cu-Mg alloy by micro-arc oxidation [J]. Appl Surf Sci, 2006, 253: 674–678.

WEI Tong-bo, YAN Feng-yuan, TIAN Jun. Characterization and wear- and corrosion-resistance of microarc oxidation ceramic coatings on aluminum alloy [J]. Journal of Alloys and Compounds, 2005, 389: 169–176.

LIANG Jun, HU Li-tian, HAO Jing-cheng. Characterization of microarc oxidation coatings formed on AM60B magnesium alloy in silicate and phosphate electrolytes [J]. Appl Surf Sci, 2007, 253: 4490–4496.

HAN Yong, SUN Ji-feng, HUANG Xin. Formation mechanism of HA-based coatings by micro-arc oxidation [J]. Electrochemistry Communications, 2008, 10: 510–513.

LI Jun-ming, CAI Hui, JIANG Bai-ling. Growth mechanism of black ceramic layers formed by microarc oxidation [J]. Surf Coat Technol, 2007, 201: 8702–8708.

BARCHICHE C E, ROCCA E, HAZAN J. Corrosion behaviour of Sn-containing oxide layer on AZ91D alloy formed by plasma electrolytic oxidation [J]. Surf Coat Technol, 2008, 202: 4145–4152.

LIANG Jun, HU Li-tian, HAO Jing-cheng. Improvement of corrosion properties of microarc oxidation coating on magnesium alloy by optimizing current density parameters [J]. Appl Surf Sci, 2007, 253: 6939–6945.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2008BAE63B00) supported by the National Key Technologies Research and Development Program of China

Rights and permissions

About this article

Cite this article

Yang, W., Jiang, Bl., Shi, Hy. et al. Effects of KMnO4 on microstructure and corrosion resistance of microarc oxidation coatings on 2024 aluminum alloy. J. Cent. South Univ. Technol. 17, 223–227 (2010). https://doi.org/10.1007/s11771-010-0034-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-010-0034-2