Abstract

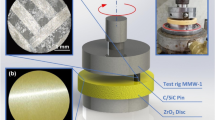

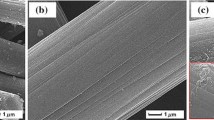

C/C-SiC composites with SiC island distribution were prepared via a new processing route. The fabrication process mainly included silicon infiltration by ultrasonic vibration, chemical vapor deposition (CVD), siliconizing, liquid phase impregnation and carbonization. The wear and friction properties were tested by an MM-1000 wet friction machine. The results show that SiC phases are mainly distributed between carbon fibers and pyrocarbons as well as among the pryocarbons. The dynamic friction coefficient of the composites decreases gradually from 0.126 to 0.088 with the increase of the surface pressure from 0.5 to 2.5 MPa at the same rotary speed. Furthermore, under the constant surface pressure, the dynamic friction coefficient increases from 0.114 to 0.126 with the increase of the rotary speed from 1 500 to 2 500 r/min. However, the coefficient decreases to 0.104 when the rotary speed exceeds 4 500 r/min. During the friction process, the friction coefficient of C/C-SiC composite is between 0.088 and 0.126, and the wear value is zero after 300 times brake testing.

Similar content being viewed by others

References

POSER K, GAHR K H ZUM, SCHNEIDER J. Development of Al2O3 based ceramics for dry friction systems [J]. Wear, 2005, 259(1/6): 529–538.

YU Hai-jiao, ZHOU Xin-gui, WANG Hong-lei, ZHAO Shuang, YANG Jian-gao, HUANG Ze-lan. Processing and properties of 2D SiC/SiC composites by precursor infiltration and pyrolysis [J]. Journal of Central South University of Technology, 2009, 16(2): 190–194.

EGUCHI M, YAMAMOTO T. Shear characteristics of a boundary film for a paper-based wet friction material: friction and real contact area measurement [J]. Tribology International, 2005, 38(3): 327–335.

PAN X D. Wet sliding friction of elastomer compounds on a rough surface under varied lubrication conditions [J]. Wear, 2007, 262(5/6): 707–717.

WIRTH A, EGGLESTON D, WHITAKER R. A fundamental tribochemical study of the third body layer formed during automotive friction braking [J]. Wear, 1994, 179(1/2): 75–81.

FAN Yi, LIU Bo-wei. Effect of sintering pressure on behaviours of copper-base wet frictional materials [J]. Materials Science and Engineering of Powder Metallurgy, 2002, 7(3): 228–232. (in Chinese)

CAI Dan, WEI Chen-guan, SONG Wen-yue. Friction discs distortion phenomena in wet clutch [J]. Journal of Beijing Institute of Technology, 2000, 20(4): 449–451. (in Chinese)

WANG Xiu-fei. Investigation on fabrication and performance of C/C-SiC composites for tank clutch [D]. Changsha: Central South University, 2007. (in Chinese)

AUDEBERT N, BRABER J R, ZAGRODZKI P. Buckling of automatic transmission clutch plates due to thermo-elastic/plastic residual stresses [J]. Journal of Thermal Stresses, 1998, 21(3): 309–326.

KRENKEL W, HEINDENREICH B, RENZ R. C/C-SiC composites for advanced friction systems [J]. Advanced Engineering Materials, 2002, 4(7): 427–436.

YU Yong-dong, ZHANG Li-tong, CHENG Lai-fei, HAN Jin-tan. Fiber reinforced ceramic matrix composites prepared by chemical vapor infiltration [J]. Journal of the Chinese Ceramic Society, 1995, 23(3): 319–326. (in Chinese)

HE Xin-bo, ZHANG Chang-rui, ZHOU Xin-gui. Effect of pyrolytic carbon coating on mechanical properties of Cf/SiC composites [J]. High Technology Letters, 2000, 10(9): 92–94.

ZHANG G B, GUO Q G, WANG K J, ZHANG H, SONG Y, SHI J L, LIU L. Finite element design of SiC/C functionally graded materials for ablation resistance application [J]. Materials Science and Engineering: A, 2008, 488,(1/2): 45–49.

MA Yun-zhu, HUANG Bai-yun, XIONG xiang, XIAO Peng, LI Jiang-hong, HUANG Qi-zhong, YI Mao-zhong. Effect of infiltrating Si on friction properties of C/C composites [J]. Journal of Central South University of Technology, 2003, 10(3): 173–176.

DING Hua-dong, HAN Wen-zheng, FU Su-li, DU Jian-hua, YU Yuan-hong. Design and manufacture of intelligent Cu-based wet friction materials [J]. Transactions of Nonferrous Metals Society of China, 2004, 14(5): 864–869.

XIONG X, CHEN J, YAO P P, LI S P, HUANG B Y. Friction and wear behaviors and mechanisms of Fe and SiO2 in Cu-based P/M friction materials [J]. Wear, 2007, 262(9/10): 1182–1186.

MUKHERJEEA S, SARKAR K. Effects of viscosity ratio on deformation of a viscoelastic drop in a Newtonian matrix under steady shear [J]. Journal of Non-Newtonian Fluid Mechanics, 2009, 160(2/3): 104–112.

HOLGERSON M. Apparatus for measurement of engagement characteristics of a wet clutch [J]. Wear, 1997, 213(1/2): 140–147.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2006CB600901) supported by the Major State Basic Research and Development Program of China; Project(0991015) supported by Guangxi Science Found, China; Project(200808MS083) supported by Guangxi Education Department Found

Rights and permissions

About this article

Cite this article

Wang, Xf., Yin, Cl., Huang, Qz. et al. Wet friction performance of C/C-SiC composites prepared by new processing route. J. Cent. South Univ. Technol. 16, 525–529 (2009). https://doi.org/10.1007/s11771-009-0087-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-009-0087-2