Abstract

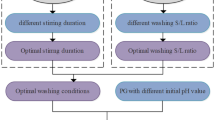

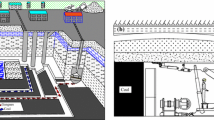

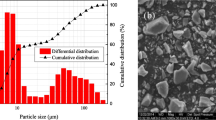

Physical-chemical properties of phosphorous gypsum, proportion and cemented mechanism of slurry with gypsum as aggregate were studied to remove the harms of gypsum pile, combining with difficult problems of excessive mined-out gobs, enormous ore body under roadway and low recovery ratio of Yongshaba Mine, Kaiyang Phosphor Mine Group, Guizhou Province, China. An appropriate backfill system and craftwork were designed, using shattering milling method to crush gypsum, double-axles mixing and strong activation mixing way to mix slurry, cemented slurry and mullock backfill alternately process. The results show that gypsum is fit for backfilling afterwards by adding fly ash, though it is not an ideal aggregate for fine granule and coagulate retardation. The suggested dosage (the mass ratio of cement to fly ash to gypsum) is 1:1:6–1:1:8 with mass fraction of solid materials 60%–63%. Slurry is transported in suspend state with non-plastic strength, and then in concretion state after backfilling. The application to mine shows the technology is feasible, and gypsum utilization ratio is up to 100%. Transportation and backfill effect is very good for paste-like slurry and drenching cemented slurry into mullock, and the compressive strength and recovery ratio are 2.0 MPa and 82.6%, respectively, with the maximum subsidence of surface only 1.307 mm. Furthermore, the investment of system is about 7×106 yuan (RMB), only 1/10 of that of traditional paste backfill system.

Similar content being viewed by others

References

SEOG K K, YONG J P, SANG L, YUNMI K L. Efficiency of gypsum as a capping material for the capturing of phosphorus release from contaminated lake sediments [J]. Materials Science Forum (Switzerland), 2007, 544/545: 561–564.

JI J. Study on dephosphorization the technology for high-phosphorus iron ore [J]. Mining & Metallurgy, 2003, 12(2): 33–37. (in Chinese)

China Environment Protection Bureau. Investigation report on damage and rebuild of ecology & environment in mine development [R]. Beijing: China Environment Protection Bureau, 2004. (in Chinese)

KURAHASHI T, SHIOMI H, KITAGUTI S, SHIRAKAWA M. Effect of addition to the gypsum on phosphorous removal properties of wollastonite-type adsorbent [J]. Journal of the Society of Materials Science, Japan, 2007, 56(6): 516–520.

WANG Xin-min, YAO Jian, TIAN Dong-mei, ZHANG Qin-li. Test research on performances of phosphorous gypsum as aggregate for cementation filling [J]. Metal Mine, 2005(12): 14–16. (in Chinese)

DENG Jian, BIAN Li. Investigation and characterization of mining subsidence in Kaiyang Phosphorus Mine [J]. Journal of Central South University of Technology, 2007, 14(3): 413–417.

SHEN Wei-guo, ZHOU Ming-kai, ZHAO Qing-lin. Study on lime-fly ash-phosphogypsum binder [J]. Construction & Building Materials, 2007, 21(7): 1480–1485.

HOU Hao-bo, HE Xing-hua, ZHU Shu-jing, ZHANG Da-jie. The cement solidification of municipal solid waste incineration fly ash [J]. Journal of Wuhan University of Technology: Material Science Edition, 2006, 21(4): 137–140.

BAO Lin-lin, LI Dong, LI Xiang-kun, HUANG Rong-xin, ZHANG Jie, LÜ Yang, XIA Guang-qing. Phosphorus accumulation by bacteria isolated from a continuous-flow two-sludge system [J]. Journal of Environment Sciences, 2007, 19(4): 391–395.

YAN Pei-yu, ZHOU Yong-xiang, YANG Zhen-jie, QIN Jian. Microstructure formation and degradation mechanism of cementitious plugging agent slurries [J]. Journal of Wuhan University of Technology: Material Science Edition, 2007, 22(1): 61–65.

JIANG Zeng-guo, ZHAO Yuan. Mechanism and optimal application of chemical additives for accelerating early strength of lime-fly ash stabilized soils [J]. Journal of Wuhan University of Technology: Material Science Edition, 2005, 20(3): 110–112.

QIAN Jue-shi. Fly ash characteristic and fly ash concrete [M]. Beijing: Science Press, 2002. (in Chinese)

KESIMAL A, YILMAZ E, ERCIKDI B. Evaluation of paste backfill mixtures consisting of sulphide-rich mill tailings and varying cement contents [J]. Cement and Concrete Research, 2004, 34(10): 1817–1822.

ZHAO Cai-zhi, ZHOU Hua-qiang, QU Qun-di. Preliminary test on mechanical properties of paste filling material [J]. Journal of China University of Mining & Technology, 2004, 33(2): 159–161. (in Chinese)

WANG Xin-min, XIAO Wei-guo, ZHANG Qin-li. Deep mining backfill theory and technology [M]. Changsha: Central South University Press, 2005. (in Chinese)

PENG Xin, LI Xi-bing, ZHANG Qin-li, WANG Xin-min. Quality evaluation of layer-like backfilling and flow pattern of backfill slurry in stope [J]. Journal of Central South University of Technology, 2007, 14(4): 580–583.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (2006BAB02A03) supported by the National Key Technology Research and Development Program; Project (08MX16) supported by Mittal Scientific and Technological Innovation Projects of Central South University during 2008

Rights and permissions

About this article

Cite this article

Wang, Xm., Zhao, B. & Zhang, Ql. Cemented backfill technology based on phosphorous gypsum. J. Cent. South Univ. Technol. 16, 285–291 (2009). https://doi.org/10.1007/s11771-009-0049-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-009-0049-8