Abstract

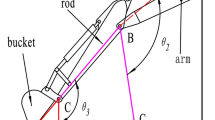

Based on the working principle of vibratory excavation of hydraulic excavator, the expression of digging resistance changed with time under sine wave inspiritment was deduced; a comparison analysis was given after calculating the forces status of rock and soil under static load and vibratory load respectively by using MATLAB; and then RFPA-2D(rock failure process analysis code) was used to make comparison of simulation experiment on rock and soil failure process under static load and vibratory load. The results demonstrate that, compared with the normal excavation under the same situation, the digging resistance and the energy consumption can be reduced by respectively 30% and 60% at maximum, and that the working efficiency can be increased by 45% at maximum owing to vibratory excavation.

Similar content being viewed by others

References

KEITH S E, BRAMMER A J. Rock drill handle vibration: Measurement and hazard estimation [J]. Journal of Sound and Vibration, 2001, 174(4): 475–491.

YIN Yong-guang, LI Jun-ming, WANG Guo-qiang. An experimental study on two-dimension vibratory cutting soil [J]. Transactions of the Chinese Society of Agricultural Machinery, 1994, 25(2): 18–23. (in Chinese)

WILHELM J K. Novel, low-vibration excavation techniques for underground radioactive waste storage [C]// High Level Radioactive Waste Management-Proceedings of the Annual International Conference. Las Vegas: American Society of Civil Engineering, 2004: 417–429.

HORN R, VOSSBRINK J, PETH S, BECKER S. Impact of modern forest vehicles on soil physical properties [J]. Forest Ecology and Management, 2007, 248(5): 56–63.

NAQQAR E I, HESHAM M, GHAFAR C A. Vibration barriers for shock-producing equipment [J]. Canadian Geotechnical Journal, 2005, 42(1): 297–306.

QIU Li-chun, LI Bao-fa. Experimental study on the self-excited vibration subsoiler for reducing draft force [J]. Transactions of the Chinese Society of Agricultural Engineering, 2000, 16(6): 71–76. (in Chinese)

ZHAO Wei-min, ZHOU Xian-biao, LU Nian-li, LI Yi-shen. The basic research of vibratory cutting soil [J]. Construction Machinery, 2000(6): 56–60. (in Chinese)

MURO T, TRAN D T. Regression analysis of the characteristics of vibratory cutting blade for tuffaceous rock [J]. Journal of Terramechanics, 2004(40): 191–219.

ZHU Jian-xin, ZHAO Chong-you, ZOU Xiang-fu. Identification of soil parameters on vibratory excavation of hydraulic excavator [J]. Journal of Central South University: Natural Science, 2006, 37(3): 537–541. (in Chinese)

HUANG J S, PENG C Q, ZHANG S Q, HUANG B Y. Lead free cutting copper alloys [J]. The Chinese Journal of Nonferrous Metals, 2006, 16(9): 1486–1493. (in Chiense)

YUAN Qi-long, LI Yan, XIAO Ji-ming, ZHU Jian-xin, LI Peng-yang. Cutting-press compound shaping technique [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 860–864. (in Chinese)

HUANG Wen-mei. System simulation analysis and design [M]. Changsha: National University of Defence Technology Press, 2001: 313–317. (in Chinese)

TANG Chun-an, ZHAO Wen. Rock failure process analysis software system RFPA-2D [J]. Chinese Journal of Rock Mechanics and Engineering, 1997, 16(5): 507–508. (in Chinese)

HUANG Jin-song, PENG Chao-qun, ZHANG Si-qi, HUANG Bai-yun. Lead free cutting copper alloys [J]. The Chinese Journal of Nonferrous Metals, 2006, 16(9): 1486–1493. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2003AA430200) supported by the National High-Tech Research and Development Program of China

Rights and permissions

About this article

Cite this article

Zhu, Jx., Yang, Cy., Hu, Hy. et al. Reducing-resistance mechanism of vibratory excavation of hydraulic excavator. J. Cent. South Univ. Technol. 15, 535–539 (2008). https://doi.org/10.1007/s11771-008-0101-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-008-0101-0