Abstract

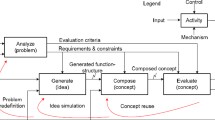

Deficiencies of applying the simple genetic algorithm to generate concepts were specified. Based on analyzing conceptual design and the morphological matrix of an excavator, the hybrid optimization model of generating its concepts was proposed, viz. an improved adaptive genetic algorithm was applied to explore the excavator concepts in the searching space of conceptual design, and a neural network was used to evaluate the fitness of the population. The optimization of generating concepts was finished through the “evolution — evaluation” iteration. The results show that by using the hybrid optimization model, not only the fitness evaluation and constraint conditions are well processed, but also the search precision and convergence speed of the optimization process are greatly improved. An example is presented to demonstrate the advantages of the proposed method and associated algorithms.

Similar content being viewed by others

References

Hyen H J, Parsaei H R, Wong J P. Concurrent engineering: The manufacturing philosophy for the 90’s [J]. Computer and Industry Engineering, 1991, 21(1–4): 34–39.

HUANG Hong-zhong, BO Rui-feng, FAN Xian-feng. Concept optimization for mechanical product using genetic algorithm[J]. Journal of Mechanical Science and Technology, 2005, 19(5): 1072–1079.

Al-Salka M A, Cartmell M P, Hardy S J. A framework for a generalized computer-based support environment for conceptual engineering design[J]. Journal of Engineering Design, 1998, 9(1): 57–88.

HUANG Hong-zhong, BO Rui-feng, CHEN Wei. An integrated computational intelligence approach to product concept generation and evaluation[J]. Mechanism and Machine Theory, 2006, 41(4): 10–27.

Strawbridge Z, McAdams D A, Stone R B. A computational approach to conceptual design[C]// Kumar V. Proceedings of ASME 2002 Design Engineering Technical Conference. Montreal: ASME, 2002: 1–11.

Ermer G, Goodman E, Hawkins R, et al. Steps towards function-based models and bond-graphs for conceptual design in engineering[J]. Automated Modeling for Design, 1993, 47(11): 47–62.

Kumar A S, Subramaniam V, Seow K C. Conceptual design of fixtures using genetic algorithms[J]. International Journal of Advanced Manufacturing Technology, 1999, 15(2): 79–84.

Ng T T H, Leng G S B. Application of genetic algorithms to conceptual design of micro-air vehicle [J]. Engineering Applications of Artificial Intelligence, 2002, 15(5): 439–445.

Miles J C, Sisk G M, Moore C J. The conceptual design of commercial buildings using a genetic algorithm [J]. Computers and Structures, 2001, 79(17): 1583–1592.

HUANG Hong-zhong, ZHAO Zheng-jia, GUAN Li-wen, et al. Intelligent conceptual design based on genetic algorithm[J]. Journal of Computer-aided Design & Computer Graphics, 2002, 14(5): 437–441. (in Chinese)

Pahl G, Beitz W. Engineering desing[M]. London: Springger-Verlag, 1984.

ZOU Hui-jun. Conceptual design of mechanical system[M]. Beijing: China Machine Press, 2003. (in Chinese)

HUANG Dong-sheng, QIU Bin, Modern excavators [M]. Beijing: China Communications Press, 2003. (in Chinese)

Srinivas M, Patnaik L M. Adaptive probabilities of crossover and mutation in genetic algorithms [J]. IEEE Transactions on Systems and Cybernetics, 1994, 24(4): 656–667.

Wu Q H, Cao Y J, Wen J Y. Optimal reactive power dispatch using an adaptive genetic algorithm[J]. International Journal of Electrical Power & Energy Systems, 1998, 20(8): 563–569.

ZHANG Li-ming. Modeling and application of neural networks [M]. Shanghai: Fudan University Press, 1993. (in Chinese)

HUANG Hong-zhong, TIAN Zhi-gang, ZUO Ming-jian. Intelligent interactive multiobjective optimization method and its application to reliability optimization [J]. IIE Transactions on Quality and Reliability, 2005, 37(11): 983–993.

HUANG Hong-zhong, TIAN Zhi-gang. Application of neural network to interactive physical programming[C] // WANG Jun, LIAO Xiao-feng, YI Zhang. ISNN 2005: The Second International Symposium on Neural Networks. Chongqing: Springer, 2005: 725–730.

HUANG Hong-zhong, SUN Zhan-quan, ZUO Ming-jian, et al. Bayesian reliability assessment of gear lifetime under fuzzy environments [C] // Adib R M, The Annual Reliability and Maintainability Symposium. Alexandria: IEEE Conference Publications, 2005: 232–237.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (50175010) supported by the National Natural Science Foundation of China; project (1766) supported by the Excellent Young Teachers Program of the Ministry of Education of China; project(200232) supported by the National Excellent Doctoral Dissertation Special Foundation of China

Rights and permissions

About this article

Cite this article

Xue, Lh., Li, Yh. Hybrid optimization model of product concepts. J Cent. South Univ. Technol. 13, 105–109 (2006). https://doi.org/10.1007/s11771-006-0115-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-006-0115-4