Abstract

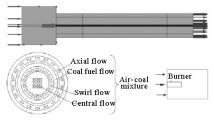

A 3-D numerical simulation with CFX software on physical field of multi-air channel coal burner in rotary kiln was carried out. The effects of various operational and structural parameters on flame feature and temperature distribution were investigated. A thermal measurement was conducted on a rotary kiln (4.5 m in diameter, 90 m in length) with four-air channel coal burner to determine the boundary conditions and to verify the simulation results. The calculation result shows that the distribution of velocity near burner exit is saddle-like; recirculation zones near nozzle and wall are useful for mixture primary air with coal and high temperature fume. A little central airflow can avoid coal backing up and cool nozzle. Adjusting the ratio of internal airflow to outer airflow is an effective and major means to regulate flame and temperature distribution in sintering region. Large whirlcone angle can intensify disturbution range at flame root to accelerate ignition and mixture. Large coal size can reduce high temperature region and result in coal combusting insufficiently. Too much combustion air will lengthen flame and increase heat loss.

Similar content being viewed by others

References

ZHANG Hong-qiang, HE De-xin, ZHU Ming-hong, et al. Flow field measurement of three passage combustion facility for cement pit [J]. Experiments and Measurements in fluid mechanics, 2001, 15(1): 64–69. (in Chinese)

YE Xu-chu, HU Dao-he, MIU Ming-feng. Numerical simulation research for swirling flow produced by multi-channel burner in the kilns[J]. Journal of Nanjing University of Chemical Technology, 1998, 20(1): 36–39. (in Chinese)

WANG Chao-qun, KONG Xue-biao. Numerical simulation on gas-particle flows of 3-channel coal burner [J]. Journal of Combustion Science and Technology, 1998, 4(2): 144–149. (in Chinese)

ZHANG Yong-jun. Speed difference swirling jet pulverized coal burner in cement rotary kiln[J]. Journal of Combustion Science and Technology, 2000, 6(3): 275–277. (in Chinese)

HOU Ling-yun, FU Wei-biao, ZHANG Yong-jun. A theoretical analysis on combustion intensification for blended coal in rotary cement kiln [J]. Fuel, 2001, 80(11): 1645–1650.

ZHOU Li-xing. Theory and numerical simulation of turbulent gas-particle flows and combustion [M]. CHEN Wen-fang, LIN Wen-yi, translate. Beijing: Science Press, 1994. (in Chinese)

ZHOU Li-xing. Dynamics of multiphase turbulent reacting fluid flows [M]. Beijing: Defense Industry Press. 2002. (in Chinese)

Li Z Q, Wei F, Jin Y. Numerical simulation of pulverized coal combustion and NO formation[J]. Chemical Engineering Science, 2003, 58: 5161–5171.

Ma A C, Zhou J M, Li W X. Parameters optimization of four-air channel pulverized coal burner in rotary kiln [C]. 3rd I-CIPEC. Beijing: Beijing Publishing Corporatin, International Academic Press, 2004: 94–97.

Abbas T, Charoensuk J, Lockwood F C, et al. The performance of pulverized coal flames in a simulated combined cycle unit [J]. Combustion and Flame, 1997, 111: 111–123.

Lockwood F C, Mahmud T, Yehia M A. Simulation of pulverized coal test furnace performance[J]. Fuel, 1998, 77(12): 1329–1337.

FAN Wei-cen, WAN Yue-peng. Models and computation of flow and combustion [M]. Hefei: China Science and Technology University Press, 1992. (in Chinese)

MA Ai-chun, ZHOU Jie-min, LI Wang-xing. Study on energy saving in soda-lime sintering process of alumina production [J]. Metallurgical Energy, 2003, 22(2): 7–10. (in Chinese)

LI Xin-feng. Application of CFD technology on flash smelting cupper [D]. Changsha: Central South University, 2001. (in Chinese)

TAO Wen-quan. Numerical heat transfer [M]. Xi’an: Xi’an Jiaotong University Press, 1988. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(20010533009) supported by the Special Foundation for Doctorate Discipline of China

Rights and permissions

About this article

Cite this article

Ma, Ac., Zhou, Jm., Ou, Jp. et al. CFD prediction of physical field for multi-air channel pulverized coal burner in rotary kiln. J Cent. South Univ. Technol. 13, 75–79 (2006). https://doi.org/10.1007/s11771-006-0110-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-006-0110-9