Abstract

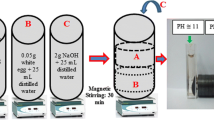

Gelatin — carbonyl iron composite particle was prepared by micro emulsion method. The analysis of scanning electron microscope(SEM) shows that the ultrafine particles are spheroids coated by gelatin, and the average sizes of particles are 3 – 10 µm. The specific saturation magnetization σs is 130.9 A · m2/kg, coercivity H c is 0.823 A/m, and residual magnetism r is 4.98 Am2/kg for the composite particles. It is shown that the particles possess properties of soft magnetic. The yield stress of magnetorheological fluid (MRF) with composite particle reaches 70 kPa at 0.5 T magnetic induction. Magnetorheological effects are superior in lower magnetic field intensity and the subsidence stability of the MRF is excellent compared with pure carbonyl iron powder.

Similar content being viewed by others

References

YAN Jian-hui, HUANG Ke-long, DAI Xiao-yuan. Preparation of inorganic functional nano-materials from reverse micelle microemulsion[J]. Fine Chemical Intermediates, 2003, 33(3): 4–7. (in Chinese)

NI Yong-hong, GE Xue-wu, XU Xiang-ling, et al. Study progress of nanometer material preparation [J]. Journal of Inorganic Mater, 2000, 15(1): 9–15. (in Chinese)

SUN Ji-hong, ZHANG Ye, FAN Wen-hao, et al. Solgel technique and chemical clipping of nanometer material [J]. Progress of Chemistry, 1999, 11(1): 80–85. (in Chinese)

XIA He-sheng, WANG Qi. Advances in polymer nanomaterials II. polymer/inorganic nanocomposites [J]. Chemical Research and Application, 2002, 14(2): 127–132. (in Chinese)

YANG F, OU Y C, YU Z Z. Polyamide/silica nanocomposites prepared by in-situ polymerization [J]. J App Polym Sci, 1998, 69(2): 355–360.

YANG Shi-qing, PENG Bin, WANG Hao-cai, et al. Fabrication and rheological properties on ultrafine Co-Ni composite magnetorheological fluids [J]. Journal of Functional materials, 2001, 32(2): 142–147. (in Chinese)

LIN Jin-gu, WANG Yao-ju, ZOU Bin-suo, et al. Study of Fe-Co nanometer particle preparation with supersonic resolution method [J]. Journal of Chemistry Physics, 1996, 9(3): 262–265. (in Chinese)

LIU Cheng-lin, LI Yuan-guang, ZHONG Ju-hua, et al. Study of α-Fe2O3 ultrafine particle with LB membrane technology assembly [J]. Journal of Chemistry Physics, 1998, 11(2):156–160. (in Chinese)

ZHANG Chao-ping, DENG Wei, HU Zhong-chao, et al. Preparation of ultrafine Fe particles with microemulsion method [J]. Chinese Journal of Apply Chemistry, 2000, 17(3): 248–251. (in Chinese)

ZHANG Chao-ping, DENG Wei, HU Lin, et al. Preparation of ultrafine Ni-Fe composite particle by microemulsion [J]. Journal of Inorganic Material, 2001, 16(3): 481–485. (in Chinese)

Haram S K, Mahadeshwar A R, Sharad G D. Synthesis and characterization of copper sulphide nanoparticles in aqueous surfactant solutions[J]. Adsorption Science and Technology, 1998, 16(8): 667–677.

ZHANG Yan, ZOU Bing-suo, XIAO Liang-zhi, et al. Preparation and characterization of monodisperse ultrafine ferric oxide by micro emulsion method[J]. Acta Scientiakum Naturalium Universitatis Jilinensis, 1990, 20(4): 115–119. (in Chinese)

Zarur A J, Ying J Y. Reverse microemulsion synthesis of nanostructure complex oxide fir catalytic combustion [J]. Nature, 2000, 403: 65–67.

Coulter J P, Weiss K D, Carlson J D. Engineering applications of electrorheological materials[J]. Journal of Intelligent Materials Systems and Structures, 1993, 2(4): 248–259.

ZHAO Su-ling, SU Liang-bi, GUAN Jian-guo, et al. The Preparation and character of carbonyl iron[J]. Journal of Wuhan University of Technology, 2004, 26(2): 7–10. (in Chinese)

GUAN Jian-guo, WANG Wei, GONG Rong-zhou, et al. Properties of magnetorheolgical suspension for filled clusters of cobalt — phthalocyanine/iron nanoparticles[J]. Chinese Journal of Chemical Physics, 2000, 13(4): 508–512. (in Chinese)

WANG Hua, ZHOU Gang-yi, FANG Sheng, et al. An investigation on the shear property of MR elastomer by dynamic experiment[J]. Journal of Experimental Mechanics, 2004, 19(1): 1–5. (in Chinese)

JIN Jun, ZHANG Pei-qiang, WANG Xiao-hua, et al. Numeric computation on shear yield stress of magnetorheology fluids [J]. Journal of University of Science and Technology of China, 2001, 31(2): 168–173. (in Chinese)

Carlson J D. Magnetorheological fluid actuators[A]. Janocha H. Adapt ionics and Smart Structures[C]. Berlin: Springer-verlag Berlin Heidelberg, 1999. 180–195.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pan, Hj., Huang, Hj., Zhang, Lz. et al. Rheological properties of magnetorheological fluid prepared by gelatin — carbonyl iron composite particles. J Cent. South Univ. Technol. 12, 411–415 (2005). https://doi.org/10.1007/s11771-005-0173-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0173-z