Abstract

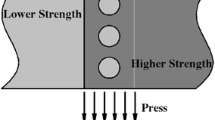

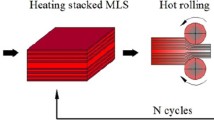

One of the key problems by diffusion-rolling bonding with small reduction for carbon steel plates is the bonding assistant coat. A bonding assistant coat used below 850 °C was developed. It contained copper as basic element and zinc as main alloy element. Other small elements and rare metals were added to decrease the melting point and to obtain a better clouding and high plasticity. Based on the theory of brazing and transient liquid diffusion welding, two carbon steel plates were rolled with small reduction by using self-made bonding assistant coat. Temperature, pressure and holding time are the main technology parameters for controlling the process of diffusion-rolling. The results show that the bonding strength is the greatest when the bonding temperature is 830 °C, holding time is 3 min and the reduction rate is 9%.

Similar content being viewed by others

References

ZOU Mo-lian. Transient liquid phase diffusion welding [J]. Aviation Precision Manufacturing Technology, 1993, 29(4): 22–24. (in Chinese)

Suk M J, Kwon Y S, Kim J S, et al. Transient liquid phase bonding process using liquid phase sintered alloys as an interlayer material[J]. Journal of Materials Science, 2002, 35(8): 1917–1919.

QU Wen-qin, ZHANG Yan-hua. Advancement of TLP bonding technology[J]. Welding Technology, 2002, 31(3): 4–7. (in Chinese)

LI Zhi-yuan, QIAN Yi-yu, ZHANG Jiu-hai. Advanced Joining Method[M]. Beijing: Mechanical Industry Press, 2000. (in Chinese)

ZHAO Xi-hua. Pressure Welding[M]. Beijing: Mechanical Industry Press, 2001. (in Chinese)

FU Ding-mei, Research and Development of a New Bonding Assistant Coat Used in Steel Honeycomb Sandwich Panels[D]. Beijing: University of Science and Technology Beijing, 2004. (in Chinese)

MENG Qing-lian. A Bonding Assistant Coat Used for Metal[P]. China: 94108027.7, 1994-08-04. (in Chinese)

ZENG Qiu-lian, ZHANG Ai-sheng, WEI Xiu-qin. Effects of trace RE and B on copper and its alloy[J]. Special Casting and Nonferrous Alloy, 2002, (3): 55–57. (in Chinese)

WAN Qun, LU Hong. Application of RE in phosphor copper brazing filler metal[J]. Jiangxi Metallurgy, 2002, 22(6): 18–20. (in Chinese)

HU De-lin, ZHANG Fan. Ternary Phase Diagram [M]. Xi’an: Northwestern Polytechnical University Press, 1995. (in Chinese)

Liu S, Olsen D L, Martin G P, et al. Modeling of brazing processes that use coating and interlayer[J]. Welding Journal, 1991, 70(8): 207–215.

ZHANG Gui-feng, ZHANG Jian-xun, WANG Shi-yuan. Similarities and differents in main characteristics between transient liquid phase bonding and brazing process[J]. Transactions of the China Welding Institution, 2002, 23(6): 92–97. (in Chinese)

Tuah-Poku I, Dollar M, Massalski T B. A study of the transient liquid phase bonding process applied to a Ag/Cu/Ag sandwich joint[J]. Metallurgical Transactions A, 1988, 19A(3): 675–686.

YU Jiu-ming, FANG Xiao-ying, XIAO Yun-zhen. Liquid and solid bonding strength of Cu/Fe interface in copper clad steel[J]. Chinese Journal of Materials Research, 2000, 14(6): 661–664. (in Chinese)

ZOU Xi. Brazing[M]. Beijing: Mechanical Industry Press, 1995. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, J., Han, Jt. & Fu, Dm. Bonding strength in carbon steel sandwich panels under condition of diffusion-rolling with small reduction. J Cent. South Univ. Technol. 12, 393–395 (2005). https://doi.org/10.1007/s11771-005-0168-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0168-9