Abstract

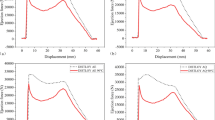

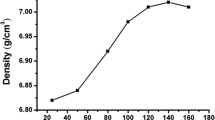

In order to reduce powder temperature to lower than 100 °C in warm compaction by changing polymer lubricant design, powder flowability, warm compacting behavior, lubricating mode as well as ultimate tensile strength after sinter-hardening and tempering were investigated systematically. By means of low temperature warm pressing and sintered hardening technique, samples with the sintered densities of 7.40 – 7.45 g/cm3 and the strengths of 950 –1 390 MPa are achieved as the early compacting pressure is 686 – 735 MPa.

Similar content being viewed by others

References

Rutz H G, Hanejko F G. High density processing of high performance ferrous materials[A]. Terry C M, Narasimnam K S. Advances in Powder Metallurgy & Particulate Materials [C]. Princeton: MPIF, 1994. 117–124.

Laurent S S T, Chagnon F. Key Parameters for warm compaction of high density materials[A]. Terry C M, Narasimnam K S. Advances in Powder Metallurgy & Particulate Materials [C]. Princeton: MPIF, 1996. 125–138.

Rutz H G, Hanejko F G, Luk S H. Warm compaction offers high density at low cost[J]. Metal Powder Report, 1994, 49(9): 40–47.

LI Yuan-yuan, Nqai T L, XIAO Zhi-yu, et al. Study on mechanical properties of warm compacted iron-base materials[J]. Journal of Central South University of Technology, 2002, 9(3): 154–158.

GUO Shi-ju, LIN Tao. Phenomenological modeling of warm compaction and experimental verification [J]. Journal of University of Science and Technology Beijing: Metallurgy Materials (English Edition), 2000, 7(4): 292–295.

Lothar A M. Powder metallurgy in europe at the start of the new millennium[J]. Powder Metallurgy Industry, 2001, 11(2): 7–13. (in Chinese)

Capus J, Pickering S, Weaver A. Hoeganses offers high density at lower cost[J]. Metal Powder Report, 1994, 49(7–8): 22–24.

GUO Shi-ju, LIN Tao, LI Ming-yi. Predicting equation for adjusting glass temperature of binder used for P/M warm compaction processing[J]. Journal of University of Science and Technology Beijing: Mineral Metallurgy Materials (English Edition), 1998, 5(1): 39–40.

Capus J M. Die wall lubrication aids higher density [J]. Metal Powder Report, 1998, 53(9): 28.

Christophe N D, Athony G, German R M. Effect of lubrication mode and compaction temperature on the properties of Fe-Ni-Cu-Mo-C[J]. International Journal of Powder Metallurgy, 1998,34(2): 29–33.

Li Y Y, Nqai T L, Zhang D T, et al. Effect of die wall lubrication on warm compaction powder metallurgy[J]. Journal of Materials Processing Technology, 2002, 129(1–3): 354–358.

CAO Shun-hua, YI Jian-hong, QU Xuan-hui, et al. Design of high density powder mixtures for warm compaction[J]. J Cent South Univ Technol, 2000, 31(6): 532–535. (in Chinese)

CAO Shun-hua, HUANG Bai-yun, QU Xuan-hui, et al. Densification mechanisms of warm compaction and powder mixture designing rules[J]. Journal of Central South University of Technology, 2000, 7(1):4–6.

CAO Shun-hua, QU Xuan-hui, HUANG Bai-yun. Densification mechanism and its applications in designing powder mixtures for warm compaction[J]. Materials for Mechanical Engineering, 2002, 26(6):9–12. (in Chinese)

ZHANG Shuang-yi, LI Yuan-yuan. Progress of research on warm compaction and its densification mechanism[J]. Materials Science & Engineering, 1999, 17(4):96–100. (in Chinese)

Ttudel Y, Gagné M. Compaction behavior of high compressibility low alloy steel powders[A]. Terry C M, Narasimnam K S. Advances in Powder Metallurgy & Particulate Materials[C]. Princeton: MPIF, 1989. 63–73.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (2001AA337010) supported by the National High Technology Research and Development Program of China

Rights and permissions

About this article

Cite this article

Cao, Sh., Lin, Xp., Li, Jy. et al. Key parameters for low temperature warm compaction of high density iron-based P/M materials. J Cent. South Univ. Technol. 12, 359–365 (2005). https://doi.org/10.1007/s11771-005-0161-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0161-3