Abstract

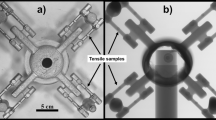

ZK60-xcerium alloys were studied, where x mass fraction is 0, 0.52%, 0.94%, 1.51% and 1.98%, respectively. Influence of Ce contents and heat-treatment on microstructure and tensile properties was analyzed. The results show that cast ZK60 alloy containing no Ce has coarse crystal grains, and lots of segregation aggregates around the grain-boundary. However, the alloys containing Ce have refined grains, and grain-boundaries are purified at the same time. Obvious dynamic recrystallization occurs in tested alloys after hot-extrusion. Tensile strength heightens with the increase of Ce content, and grows higher after aging at 150 °C for 0–24 h (T5 treatment). Comparing tensile properties of investigated alloys in different states, it can be concluded that synthetical properties of the alloy with 1.51% Ce addition is the best of all. In extruded state, σ b and δ of this alloy are 318.6 MPa and 14.4%, respectively. After aging for 24 h, σ b is 338.6 MPa and δ is 15.6%.

Similar content being viewed by others

References

Eliezer A, Gutman E M. Corrosion fatigue of die-cast and extruded magnesium alloys[J]. Journal of Light Materials, 2001, 1(3): 179–186.

Matucha K H. Structure and Properties of Nonferrous Alloys[M]. Beijing: Science Press, 1999. (in Chinese)

Polmear I J. Recent developments in light alloys[J]. Trans JIM, 1996, 37(1): 12–31.

Idris M H. Precision casting of a magnesium-base alloy[J]. Foundryman, 1997, 90(4): 140–144.

Idris M H. Processing and evaluation of investment cast magnesium-base alloy[J]. AFS Trans, 1996, 104(20–23): 237–244.

Doege E, Droder K. Sheet metal forming of magnesium wrought alloys-formability and process technology [J]. Journal of Materials Processing Technology, 2001, 115(1): 14–19.

Sanchez C, Nussbaum G. Elevated temperature behaviour of rapidly solidified magnesium alloys containing rare earths [J]. Materials Science and Engineering, 1996, 221(1–2): 48–57.

ZHANG Shi-jun, LI Wen-xian. The effect of Ce on the grain size and as-cast mechanical properties of magnesium alloy AZ31[J]. Foundry, 2002, 15(2): 767–771. (in Chinese)

Bae D H, Lee M H. Application of quasicrystalline particles as a strengthening phase in Mg-Zn-Y alloys [J]. 2002, 342(1–2): 445–450.

GU Ming-yuan, WU Zheng-an. Effects of reinforcements on the aging response of a ZK60-based hybrid composite[J]. Materials Science and Engineering, 1999, 272(2): 257–263.

MA Chun-jiang, LIU Man-ping. Tensile properties of extruded ZK60-RE alloys[J]. Materials Science and Engineering, 2003, 349(1–2): 207–212.

XU Guang-xian. Rare Earths[M]. Beijing: Metallurgical Industry Press, 2002. (in Chinese)

Machining Manual of Light Metal Group. Machining Manual of Light Metal[M]. Beijing: Metallurgical Industry Press, 1979. (in Chinese)

CUI Yue-xian, WANG Chang-li. Metal Fracture Analysis[M]. Harbin: Industry University Press, 1998. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xia, Cq., Wang, Yn., Wu, Ar. et al. Effects of cerium on microstructure and mechanical properties of ZK60 alloy. J Cent. South Univ. Technol. 12, 515–520 (2005). https://doi.org/10.1007/s11771-005-0114-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0114-x