Abstract

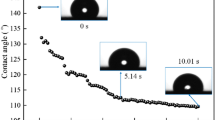

By using the experimental approach of dropping liquid, the coupling of three anionic wetting agents with ten dust samples of sulfide ores was studied, and particularly the wetting effects of the wetting agents on the sulfide dust influenced by factors of agent concentration and sulfate additive in the wetting agent solutions were investigated. The results show that the when solution temperature is about 20 °C, all the selected wetting agents are effective to most dust samples, but the effect is different. Wetting agents are more effective to the dust which is difficult to be wetted. Wetting agent solution with sodium sulfate can improve the wetting ability of sulfide dust. For sodium dodecyl benzene sulfonate, the suitable concentration of sodium sulfate is 1 – 2 mmol/L. The cost of wetting agents can be reduced because the sodium sulfate is much cheaper than many surfactants. Since the dust of sulfide ores is composed of various minerals and elements, the whole effect of depressing dust should be considered while innovating a wetting agent.

Similar content being viewed by others

References

WU Chao. Chemical Suppression of Dust[M]. Changsha: Central South University Press, 2003. (in Chinese)

Wu C, Chugh Y P. A comprehensive survey of chemical dust suppressants in the world over the last 15 years[A]. Progress in Safety Science and Technology[C]. Beijing: Chemical Industry Press, 2000, 705–719.

Polat M, Polat H, Chander S, et al. Characterization of airborne particles and droplets: Relation to amount of airborne dust and dust collection efficiency [J]. Particle and Particle Systems Characterization, 2002, 19(1): 38–46.

Bartell W, Jett B. The technology of spraying for dust suppression[J]. Rock Products, 2005, 108(5S): 32–37.

Axel C P, Lindeberg B R L, Nilsson T, et al. Simultaneous extraction of di(2-ethylhexyl) phthalate and nonionic surfactants from house dust: concentrations in floor dust from 15 Danish schools[J]. Journal of Chromatography A, 2003 (2): 179–190.

Kilau W H, Pahlman J E. Coal wetting ability of surfactant solutions and the effect of multivalent anion additions[J]. Colloids and Surfaces, 1987, 26: 217–242.

Kim J. Effect of coal type on wetting by solutions of nonionic surfactant [J]. International Mining and Minerals, 1999, 2(14): 38–41.

Polat H, Chander S. Adsorption of PEO/PPO triblock co-polymers and wetting of coal[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 1999, 146(1): 199–212.

Shah V V. High performance wetting agents based on acetylenic glycol chemistry[J]. Adhesive Age, 1998, 41(9): 36–41.

Drummond C J, Wells D. Nonionic lactose and lactitol based surfactants: comparison of some physicochemical properties[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 1998, 141(1): 131–142.

WU Chao. Development of an in-situ soil binding agent[J]. Waste Management, 2000, 20(7): 527–535.

WU Chao, GU De-sheng. Fault tree analysis of dust suppression mechanism in a spray system by wetting agents and relevant issues [J]. Journal of Central South University of Technology, 2000, 7(3): 131–137.

WU Chao, CHEN Jun-liang, ZHOU Bo, et al. Tests of the effects of three surfactants on the penetration ability of calcium chloride and water solutions in dust [J]. Journal of Environmental Science, 1998, 10(4): 445–451.

WU Chao, GU De-sheng. Investigation of improvement on wetting coal dust by anionic surfactant added sodium sulfate[J]. Journal of Safety and Environment, 2001, 1(2): 45–49. (in Chinese)

NA Qiong. Test study on the dust suppressants for the dry sands of tailing reservoir[J]. Metal Mine, 2002(6): 45–47. (in Chinese)

HAN Fang, ZHU Ji-mao, JIN Long-zhe. Research about the capability of new dust suppression medicament[J]. Safety and Environmental Engineering, 2003, 10(4): 31–33. (in Chinese)

JIN Long-zhe, ZHU Ji-mao, REN Zhi-gang, et al. Research on anti-freezing dust depressor used to road in open pit mines[J]. Journal of University of Science and Technology Beijing, 2004, 26(1): 4–7. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(50474050) supported by the National Natural Science Foundation of China; project(20040533011) supported by the Doctorate Program Fund of China

Rights and permissions

About this article

Cite this article

Wu, C., Ou, Jc. & Zhou, B. Coupling of anionic wetting agents to dust of sulfide ores by dropping liquid method. J Cent. South Univ. Technol. 12, 737–741 (2005). https://doi.org/10.1007/s11771-005-0079-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0079-9

Key words

- dust of sulfide ores

- anionic wetting agent

- dropping liquid experiment

- concentration

- sodium sulfate

- coupling