Abstract

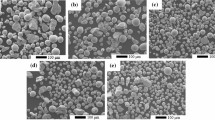

Oleic acid surface-modified Cu nanoparticles with an average size of 20 nm were prepared by liquid phase reducing reaction. The tribological performance and mechanism of nanocopper as additive were studied by means of tribotester, scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDS) and nanoindentation instrument. The results indicate that the modified nanocopper additive can significantly improve the wear resistance and reduce friction coefficient of base oil. A copper protective film is formed and contributes to the excellent tribological properties of nanocopper additive. On the basis of the film forming mechanism, a new in-situ repair method was designed and used to repair wear-out-failure injection pump plunger and barrel. Furthermore, the current research progress of nanoparticles as green energy-saving lubricating oil additives were presented.

Similar content being viewed by others

References

LIU Wei-min. Application of nanoparticles in lubricants[J]. Tribology, 2003, 23(4): 265–266. (in Chinese)

ZHAO Yan-bao, ZHANG Zhi-jun, DANG Hong-xin. Preparation of tin nanoparticles by solution dispersion[J]. Materials Science and Engineering A, 2003, 359:405–407.

Kapoor S, Dipak K P, Tulsi M. Preparation, characterization and surface modification of Cu metal nanoparticles[J]. Chemical Physics Letters, 2002, 355: 383–387.

YE Wen-yu, CHENG Tie-feng, YE Qing, et al. Preparation and tribological properties of tetrafluorobenzoic acid modified TiO2 nanoparticles as lubricant additives[J]. Materials Science and Engineering A, 2003, 359: 82–85.

ZHU Hai-tao, LIN Yu-sheng, YIN Yan-sheng. A novel one-step chemical method for preparation of copper nanofluids[J]. Journal of Colloid and Interface Science, 2004, 277: 100–103.

ZHOU Jing-fang, YANG Jian-jun, ZHANG Zhi-jun, et al. Study on the structure and tribological properties of surface-modified Cu nanoparticles[J]. Materials Research Bulletin, 1999, 34(9): 1361–1367.

YU He-long, XU Yi, LIU Qian, et al. Tribological behavior of nano-Cu particles as 50CC lubricating oil additive[J]. China Surface Engineering, 2005, 18(2): 23–26. (in Chinese)

Makowski, Romuald. Evaluation of the effect of metal particles in a lubricant on surface layer state[J]. Tribologia, 2001, 32(4): 669–676.

Mishina H. Surface deformation and formation of original element of wear particles in sliding friction[J]. Wear, 1998, 215: 10–17.

Rapoport L, Lvovsky M, Lapsker I, et al. Friction and wear of bronze powder composites including fullerene-like WS2 nanoparticles[J]. Wear, 2001, 249: 150–157.

Rapoport L, Leshchinsky V, Lvovsky M, et al. Load bearing capacity of bronze, iron and iron-nickel powder composites containing fullerene-like WS2 nanoparticles[J]. Tribology International, 2002, 35: 47–53.

Tarassov S, Kolubaev A. Effect of friction on subsurface layer microstructure in austenitic and martensitic steels[J]. Wear, 1999, 231: 228–234.

YU He-long, XU Yi, LIU Qian, et al. Study on improving tribological behavior of iron-base tribo-paris by applying Cu nanoparticles under oil lubrication[J]. Lubrication Engineering, 2005(4): 59’61. (in Chinese)

XU Bin-shi, ZHANG Wei, LIU Shi-can, et al. Smart self-repairing technology for modern equipment[J]. China Surface Engineering, 2004, 17(1): 1–4. (in Chinese)

Tarasov S, Kolubaev A, Belyaev S, et al. Study of friction reduction by nanocopper additives to motor oil[J]. Wear, 2002, 252: 63–69.

Frishberg I V, Kishkoparov N V, Zolotukhina L V, et al. Effect of ultrafine powders in lubricants on performance of friction pairs[J]. Wear, 2003, 254: 645–651.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (50235030) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Yu, Hl., Xu, Bs., Xu, Y. et al. Design of wear-out-failure in-situ repair parts by environment-friendly nanocopper additive. J Cent. South Univ. Technol. 12, 215–220 (2005). https://doi.org/10.1007/s11771-005-0044-7

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0044-7

Key words

- Cu nanoparticles

- lubricating oil additive

- tribological performance

- Cu protective film

- in-situ repair

- injection pump plunger and barrel