Abstract

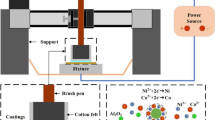

Ni/n-SiO2 composite coating was electrodeposited by brush-plating with pulse-reverse current(RC). The morphology, hardness, and tribological properties of the coating were investigated and compared with those of Ni and composite coatings electrodeposited with direct current (DC). The results indicate that Ni/n-SiO2 composite coating electrodeposited by RC, because of RC and the nano powders, has denser coating, finer crystal grains, higher hardness (HV650.0, nearly 1.5 times higher than that of Ni coating electrodeposited by DC) and lower friction coefficient (nearly 0.62), as a result, in the wearing experiment, the Ni/n-SiO2 composite coating electrodeposited by RC has the least worn loss. So this kind of coating has better wear resistance. And RC electro brush-plating can be used as a new technology of brush-plating in the area of wear resistance.

Similar content being viewed by others

References

Vidrine A B, Podlaha E J. Composite electro-deposition of ultrafine γ-alumina particles in nickel matrices [J]. J Appl Electrochem, 2001, 31: 461–468.

Podlaha E J, Landolt D. Pulse-reverse plating of nanocomposite thin films [J]. J Electrochem Soc, 1997, 144(7): 200–202.

Tang P T, Watanabc T. Improved corrosion resistence of pulse plated nickel through crystallization control [J]. J Appl Electrochem, 1995, 25(4): 347–352.

XIANG Guo-pu. The development of pulse plating [J]. Plating and Finishing, 2000, 19(4): 43–47. (in Chinese)

GUAN Zi-dong, GUO Hai-feng, ZHANG Qun. Manufacture of reverse-pulse plating power resource [J]. Plating and Environment Protection, 1995, 15(1): 22–23. (in Chinese)

ZHU Rui-an, GUO Zhen-chang. Pulse Plating [M]. Beijing: Electron Industry Press. 1986. 256–264. (in Chinese)

Dini J W. Brush plating recent property data [J]. Metal Finishing, 1997(6): 88–93.

Vanek D. An update on brush plating [J]. Metal Finishing, 2000(7): 18–20.

Stojak J L, Talbot J B. Investigation of electro co-deposition using a rotating cylinder electrode [J]. Journal of the Electrochemical Society, 1999, 146(12): 4504.

XU Bin-shi, ZHU Shao-hua. Theories and Technologies on Surface Engineering [M]. Beijing: National Defense Industry Press, 1999. 200–205. (in Chinese)

JIANG Bin, XU Bin-shi, DONG Shi-yun, et al. Study on microstructures and sliding wear performance of n-Al2O3/Ni composite coating [J]. Material Engineering, 2002, 9: 33–36. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (50235030) supported by the National Natural Science Foundation of China; Project (51489020104JS9102) supported by the National Key Laboratory for Remanufacturing

Rights and permissions

About this article

Cite this article

Tan, J., Guo, Wc., Yang, Hj. et al. Morphology and tribological properties of Ni/n-SiO2 composite coatings by pulse-reverse current brush-plating. J Cent. South Univ. Technol. 12, 172–175 (2005). https://doi.org/10.1007/s11771-005-0034-9

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0034-9