Abstract

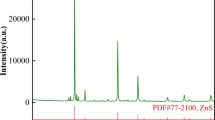

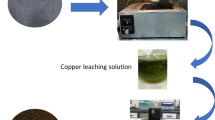

In order to utilize the chemical energy in hydrometallurgical process of sulfide minerals reasonably and to simplify the purifying process, the electrogenerative process was applied and a dual cell system was introduced to investigate FeCl3 leaching of nickel sulfide concentrate. Some factors influencing the electrogenerative leaching, such as electrode structure, temperature and solution concentration were studied. The results show that a certain quantity of electrical energy accompanied with the leached products can be acquired in the electrogenerative leaching process. The output current and power increase with the addition of acetylene black to the electrode. Varying the components of electrode just affects the polarization degree of anode. Increasing FeCl3 concentration results in a sharp increase in the output of the leaching cell when c(FeCl3) is less than 0.1 mol/L. The optimum value of NaCl concentration for electrogenerative leaching nickel sulfide concentrate with FeCl3 is 3.0 mol/L. Temperature influences electrogenerative leaching by affecting anodic and cathodic polarization simultaneously. The apparent activation energy is determined to be 34. 63 kJ/mol in the range of 298 K to 322 K. The leaching rate of Ni2+ is 29.3% after FeCl3 electrogenerative leaching of nickel sulfide concentrate for 620 min with a filter bag electrode.

Similar content being viewed by others

References

Langer S H, Yurchak S. Electrochemical reduction of the benzene ring by electrogenerative hydrogenation [J]. J Electrochem Soc, 1969, 116(9): 1228–1229.

ZHANG Heng-zhong, FANG Zheng, ZHANG Pingmin. An investigation on electrogenerative leaching of Ni3S2[A]. Proc of ICHM’1992[C]. Beijing: Inter Academic Pub, 1992. 286–289.

WANG Shao-fen, FANG Zheng, CHEN Yang-guo, et al. Exploration of electrogenerative leaching of PbS with FeCl3[J]. The Chinese Journal of Process Engineering, 2002, 2(3): 235–240. (in Chinese)

WANG Shao-fen, FANG Zheng, WANG Yun-yan, et al. Electrogenerative leaching of galena with ferric chloride [J]. Minerals Engineering, 2003, 16(9): 869–872.

LI Xi-ming, CHEN Jia-yong, Roland K, et al. Application of attrition grinding in acid leaching of nickel sulfide concentrate[J]. Transactions of Nonferrous Metals Society of China, 1997, 7(4): 143–147.

HUANG Nai-bao, LIANG Cheng-hao, TONG Dawei. Effect of inhibitors on corrosion behavior of copper-nickel in concentrated lithium bromide solution at high temperature[J]. Transactions of Nonferrous Metals Society of China, 2002, 12(3): 424–428.

FANG Zhao-heng. Electrodeposition of amorphous Ni-P alloy coatings[J]. Transactions of Nonferrous Metals Society of China, 1997, 7(3): 148–151.

Bredenhann R, van Vuuren C P J. Leaching behavior of a nickel concentrate in an oxidative sulphuric acid solution [J]. Minerals Engineering, 1999, 12(6): 687–692.

Maurice D, Hawk J A. Ferric chloride leaching of a mechanically activated pentlandite-chalcopyrite concentrate[J]. Hydrometallurgy, 1999, 52(3): 289–312.

Isabel L, Norma M M, Israel R, et al. The use of carbon paste electrodes with non-conducting binder for the study of minerals: chalcopyrite[J]. Hydrometallurgy, 1995, 38(3): 277–287.

Ahlberg E, Asbjornsson J. Carbon paste electrodes in mineral processing: an electrochemical study of galena[J]. Hydrometallurgy, 1993, 34(2): 171–185.

Ahlberg E, Asbjornsson J. Carbon paste electrodes in mineral processing: an electrochemical study of sphalerite [J]. Hydrometallurgy, 1994, 36(1): 19–37.

XU Zhi-hong, WAN Le-shan. Thermochemical Data Base for Inorganic Substances[M]. Beijing: Science Press, 1987. (in Chinese)

JIANG Han-ying. Physical Chemistry for Hydrometallurgy[M]. Beijing: Metallurgical Industry Press, 1984. (in Chinese)

Rao K S, Paramguru R K, Das R P, et al. The role of galvanic interaction during ammonia leaching of multi mental sulphides[J]. Mineral Processing and Extractive Metallurgy Review, 1992, 11(1): 21–37.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (50374077) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Wang, Sf., Fang, Z., Wang, Yy. et al. Electrogenerative leaching of nickel sulfide concentrate with ferric chloride. J Cent. South Univ. Technol. 11, 405–409 (2004). https://doi.org/10.1007/s11771-004-0084-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-004-0084-4