Abstract

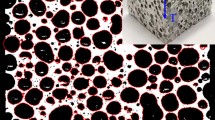

The shock wave compression behavior of the open cell aluminum foam with relative density of 0.396 was studied through planar impact experiments. Using polyvinylidene fluoride (PVDF) piezoelectric gauge technique, the stress histories and propagation velocities of shock wave in the aluminum foam were measured and analyzed. The results show that the amplitude of shock wave attenuates rapidly with increasing the propagation distance in the aluminum foam, and an exponential equation of the normalized peak stress vs propagation distance of shock wave is established, the attenuation factor in the equation is 0.286. Furthermore, the Hugoniot relation, v 5=516.85 + 1.27v p, for the aluminum foam is determined by empirical fit to the experimental Hugoniot data.

Similar content being viewed by others

References

Andrews E, Sanders W, Gibson L J. Compressive and tensile behavior of aluminum foams [J]. Mater Sci Eng, 1999, A270: 124–136.

Fusheng H, Zhengang Z. Effects of process parameters structure of foamed aluminum[J]. J Mater Sci, 1999, 34: 291–234.

Beals J T, Thomposon M S. Density gradient effects on aluminum foam compression behavior[J]. J Mater Sci, 1997, 32: 3600–3612.

Deshpande V S, Fleck N A. High strain rate compressive behavior of aluminum foam alloy foams[J]. International Journal of Impact Engineering, 2000, 24: 277–292.

Boade R R. Compression of porous copper by shock waves[J]. J Appl Phys, 1968, 39(12): 5693–5700.

Boade R R. Dynamic compression of porous tungsten [J]. J Appl Phys, 1969, 40(9): 3781–3785.

Bonnan S, Hereil P L. Experimental characterization of quasi static and shock wave behavior [J]. J App Phys, 1998, 83(11): 5711–5749.

Butcher B M. Shock-wave compression of porous aluminum[J]. J Appl Phys, 1974, 45(9): 3875–3889.

Simone A E, Gibson L J. Aluminum foams produced by liquid-state processes[J]. Acta Mater, 1998, 46(9): 3123–3143.

WEI J N, GONG C L, CHENG H F, et al. Low-frequency damping behavior of foamed commercially pure aluminum [J]. Mater Sci Eng, 2002, A332: 375–384.

Thornton P H, Magee C L. The deformation of aluminum foams[J]. Metallurgical Transactions, 1975, 6A: 1263–1278.

Tong W, Ravichandran G. Dynamic pore collapse in viscoplastic materials[J]. J Appl Phys, 1993, 74(4): 2425–2435.

Seaman L. Lagrangian analysis for multiple stress or velocity gauges in attenuation waves[J]. J Appl Phys, 1974, 45(10): 4314–4339.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(03044602) supported by the Natural Science Foundation of Anhui Province

Rights and permissions

About this article

Cite this article

Cheng, Hf., Huang, Xm., Xue, Gx. et al. Shock wave compression behavior of aluminum foam. J Cent. South Univ. Technol. 10, 333–337 (2003). https://doi.org/10.1007/s11771-003-0034-6

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11771-003-0034-6