Abstract

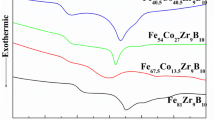

The crystallization kinetics of amorphous Nd3.6Pr5.4Fe83Co3B5 and the preparation of α-Fe/Nd2Fe14 B nanocomposite magnets by controlled melt-solidification of Nd3.6Pr5.4Fe83Co3B5 was investigated by employing DTA, XRD, and TEM. The results show that a metastable intermediate phase Nd8Fe27B24 prior to α-Fe and Nd2Fe14B phases is crystallized as the amorphous Nd3.6Pr5.4Fe83Co3B5 is heated to 1 223 K. The crystallization activation energy of α-Fe and Nd8Fe27B24 phases is larger at the beginning stage of crystallization, and then it decreases with crystallized fraction x for the former and has little change when x is below 70% for the latter, which essentially results in an α-Fe/Nd2Fe14B microstructure with a relatively coarse grain size about 20–60 nm and a non-uniform distribution of grain size in the annealed alloy. The α-Fe/Nd2Fe14B nanocomposite magnets with a small average grain size about 14 nm and a quite uniform grain size distribution were prepared by controlled melt-solidification of Nd3.6Pr5.4Fe83Co3B5 at a wheel speed of 20 m · s−1 during melt-spinning. The magnets show a high maximum energy product of (BH)max=194 kJ · m−3, which is nearly twice of that of the nanocomposite magnets made by annealing the amorphous Nd3.6Pr5.4Fe83Co3B5 precursor alloy.

Similar content being viewed by others

References

Kneller E F, Hawig R. The exchange-spring magnet: a new materials principle permanent magnets [J]. IEEE Trans Magn, 1991, 27(4): 3560–3588.

Skomski R, Coey J M D. Giant energy product in nanostructured two-phase magnets[J]. Phys Rev B, 1993, 48(21): 15812–15816.

ZHANG X Y, ZHANG J W, WANG W K. Crystallization kinetics and phase transition under high-pressure of amorphous Sm8Fe85 Si2C5 alloy[J]. Acta Mater, 2001, 49(15): 3889–3897.

CHANG W C, Chiou D Y, WU S H, et al. High performance α-Fe/ Nd2Fe14B-type nanocomposites [J]. Appl Phys Lett, 1998, 72(1): 121–123.

McCormick P G, Miao W F, Smith P A I, et al. Mechanically alloyed nanocomposite magnets(invited)[J]. J Appl Phys, 1998, 83(11): 6256–6261.

Withanawasam L, Murthy A S, Hadjipanayis G C. Hysteresis behavior and microstructure of exchange couple R2Fe14B/α-Fe magnets[J]. IEEE Trans Magn, 1995, 31(6): 3608–3610.

Fischer R, Schrefl T, Kronmüller H, et al. Grain-size dependence and coercive field of isotropic nanocrystalline composite permanent magnets[J]. J Magn Magn Mater, 1996, 153(1): 35–49.

Hadjipanayis G C. Nanophase hard magnets [J]. J Magn Magn Mater, 1999, 200(2): 373–391.

Schrefl T, Fidler J, Kronmüller H. Remanece and coercivity in isotropic nanocrystalline permanent magnets[J]. Phys Rev B, 1994, 49(9): 6100–6110.

ZHANG X Y, GUAN Y, ZHANG J W. Study of interface structure of α-Fe/Nd2Fe14B nanocomposite magnets[J]. Appl Phys Lett, 2002, 80(11): 1966–1968.

ZHANG X Y, GUAN Y, YANG L, et al. Crystallographic texture and magnetic anisotropy of α-Fe/Nd2Fe14B nanocomposites prepared by controlled melt spinning[J]. Appl Phys Lett, 2001, 79(15): 2426–2428.

ZHANG X Y, ZHANG J W, WANG W K, et al. Microstructure and magnetic properties of Sm2(Fe, Si)17C x /α-Fe nanocomposite magnets prepared under high pressure [J]. Appl Phys Lett, 1999, 74(4): 597–599.

ZHANG X Y, ZHANG J W, WANG W K. A novel route for the preparation of nanocomposite magnets[J]. Advanced Materials, 2000, 12(19): 1441–1444.

ZHANG X Y, GUAN Y, ZHANG J W, et al. Evolution of interface structure of nanocomposites prepared by crystallization of amorphous alloy[J]. Phys Rev B, 2002, 66: 212103–212106.

ZHANG X Y, GUAN Y, ZHANG J W. Interfacial structure in α-Fe/Sm2 (Fe, Si)17Cx nanocomposites prepared by crystallization of amorphous alloy[J]. J Appl Phys, 2002, 92(11): 6933–6935.

ZHANG H Y, Mitchell B S. A method for determing crystallization kinetic parameters from one nonisothemal calorimetric experiment[J]. J Mater Res, 2000, 15(4): 1000–1007.

Schroers J, Wu Y, Busch R, et al. Transition from nucleation controlled to growth controlled crystallization in Pd43Ni10Cu27P20 melts[J]. Acta Mater, 2001, 49(14): 2773–2781.

Glade S C, Löffler J F, Bossuyt S, et al. Crystallization of amorphous Cu47Ti34Zr11Ni8[J]. J Appl Phys, 2001, 89(3): 1573–1579.

ZHANG J W, ZHANG X Y, XIAO F R, et al. Influences of additive elements Nb and Mo on the crystallization process of amorphous alloy Fe76.5Cu1Si13.5B9[J]. Materials Letters, 1998, 36(4): 223–228.

Chang I T H. Handbook of Nanostructured Materials and Nanotechnology (Volume 1): Synthesis and Processing. London: Academic Press, 1999.

Kissinger H E. Reaction kinetics in differential thermal analysis[J]. Anal Chem, 1957, 29(11): 1702–1706.

Doyle C D. Kinetic analysis of thermogravimetric data[J]. J Appl Polym Sci, 1961, 5(15): 285–292.

Yoshizawa Y, Oguma S, Yamauchi K. New Fe-based soft magnetic alloys composed of ultrafine grain structure[J]. J Appl Phys, 1988, 64(10): 6044–6046.

ZHANG H W, SUN Z G, ZHANG S Y, et al. Intergrain exchange coupling and coercivity mechanism of nanocrystalline Sm2Fe15−x Cu x Si2C (x=0 and 1) ribbons prepared by melt spinning[J]. Phys Rev B, 1999, 60(1): 64–67.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., Shang, Y. Crystallization kinetics of amorphous Nd3.6Pr5.4Fe83Co3B5 and preparation of α-Fe/Nd2Fe14B nanocomposite magnets by controlled melt-solidification technique. J Cent. South Univ. Technol. 10, 280–286 (2003). https://doi.org/10.1007/s11771-003-0024-8

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11771-003-0024-8