Abstract

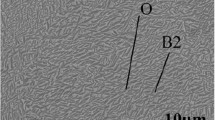

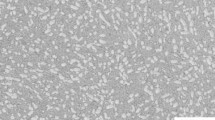

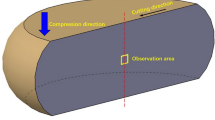

In order to establish a model between the grain size and the process parameters, the hot deformation behaviors of Ti-49.5Al alloy was investigated by isothermal compressive tests at temperatures ranging from 800 to 1 100 °C with strain rates of 10−3∓10−1 s−1. Within this range, the deformation behavior obeys the power law relationship, which can be described using the kinetic rate equation. The stress exponent, n, has a value of about 5.0, and the apparent activation energy is about 320 J/mol, which fits well with the value estimated in previous investigations. The results show that, the dependence of flow stress on the recrystallized grain size can be expressed by the equation: σ=K 1 d rex −0.56. The relationship between the deformed microstructure and the process control parameter can be expressed by the formula: 1gd rex=−0.281 1gZ + 3.9081.

Similar content being viewed by others

References

Fores F H, Suryanarayana C, Eliezer D. Review synthesis properties and applications of titanium aluminides[J]. J Mater Sci, 1992,27:5113–5140.

Bartolotta P, Barret J, Kelly T, et al. The use of cast Ti-48Al-2Cr-2Nb in jet engines[J]. JOM, 1997, 49(5): 48–50.

Yamaguchi M, Umakoshi Y. The deformation of intermetallic superlattic compounds [J]. Progress in Materials Science, 1990, 34: 1–148.

Liu C T, Maziasz P J. Microstructure control and mechanical properties of dual-phase TiAl alloy[J]. Intermetallics, 1998, 6: 653–661.

Salishchev G A, Imayev R M, Senkov O N, et al. Formation of a submicrocrystalline structure in TiAl and Ti3Al intermetallics by hot working[J]. Mater Sci and Eng, 2000, A286: 236–243.

Senkov O N, Cavusoglu M, Froes F H. Synthesis and characterization of a TiAl/Ti5Si3 composite with a submicrocrystalline structure[J]. Mater Sci and Eng, 2001, A300: 85–93.

Suryanaryana C, Froes F H. Nonostructured titanium aluminidies[J]. Mater Sci and Eng, 1994, A179/180: 108–111.

Bohn R, Klassen T and Bormann R. Room temperature mechanical behavior of silicon-doped TiAl alloys with grain sizes in the nano- and submicro- range[J]. Acta, 2001, 49: 299–311.

Bohn R, Klassen T, Bormann R. Mechanical behavior of submicron-grained γ-TiAl-based alloys at elevated temperatures[J]. Intermetallics, 2001, 9: 559–569.

Kim H Y, Sohn W H, Hong S H. High temperature deformation of Ti-(46-46) Al-2W intermetallic compounds[J]. Mater Sci and Eng, 1998, A251: 216–225.

Belyakov A, Miura H, Sakai T. Dynamic recrystallization under warm deformation of a 304 type austenitic stainless steel[J]. Mater Sci and Eng, 1998, A255: 139–147.

Author information

Authors and Affiliations

Additional information

Foundation item: Hi-Tech Research and Development Program (No. 715-005-0040)

Biography of the first author: ZHANG Jun-hong, doctoral student, born in 1970, majoring in powder metallurgy.

Rights and permissions

About this article

Cite this article

Zhang, Jh., Huang, By., He, Yh. et al. Physical simulation of hot deformation of TiAl based alloy. J Cent. South Univ. Technol. 9, 73–76 (2002). https://doi.org/10.1007/s11771-002-0045-8

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11771-002-0045-8