Abstract

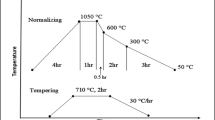

Water-atomized Fe-Ni-Mo steel powder, was utilized as base powder for designing powder mixtures for warm pressing. The warm pressing and sintering behaviours of the powder mixtures were studied. The results show that, compared with the pressing at room temperature, the green density gain by warm pressing is within a range of 0.10–0.19 g/cm3 and reduction in spring back is 30%–40% of the ambient, and maximum green density of 7.32 g/cm3 at 735 MPa is obtained as the graphite mass fraction is 0.8%. It was found that sintered densities of the compacts were reduced slightly due to releasing of elastic stress stored in the compacts during sintering. The warm pressing of steel powders gives evidence for substituting the traditional double pressing and double sintering process.

Similar content being viewed by others

References

Cimino T M, Rawlings A J, Rutz H G. Properties of several ANCORDENSE™ processed high performance materials[A]. In: Advances in P/M & Particulate Materials[C]. Terry C M ed. MPIF, 1996, 6:13-337-352.

Rutz H G, Murphy T, Cimino T M. The effect of microstructure on fatigue properties of high density ferrous P/M materials [A]. In: Advances in P/M & Particulate Materials [C]. Terry C M ed. MPIF, 1996, 6: 13-375-389.

Laurent S ST, Chagnon F. Key parameters for warm compaction of high density materials[A]. In: Advances in P/ M & Particulate Materials[C]. Terry C M ed. MPIF, 1996, 2: 5-125-138.

Rutz H G, Hanejko F G. High density processing of high performance ferrous materials[A]. In: Advances in P/ M & Particulate Materials[C]. Terry C M ed. MPIF, 1994, 5: 117–124.

Rutz H G, Hanejko F G, Luk S H. Warm compaction offers high density at low cost[J], Metal Powder Report[J], 1994, 49(9):40–47.

Christophe N D, Athony G, German R M. Effect of lubrication mode and compaction temperature on the properties of Fe-Ni-Cu-Mo-C[J]. The International Journal of Powder Metallurgy, 1998,34(2):29–33.

LI Yuan-yuan, XIANG Pin-feng, XIA Wei, et al. Warm compaction: a new technique for fabricating high performance ferrous P/M parts[J]. Guidelines for Materials, 2000, 14 (2): 25–27.

LIN Tao, GUO Shi-ju, LI Ming-yi, et al. Effects of binder and lubricant on the flowability and apparent density of iron powder[J]. Powder Metallurgy Technology, 2000, 18(1):8–11.

CAO Shun-hua, YI Jian-hong, ZHANG Li-hua, et al. Densification mechanisms and powder mixture designing rules for warm compaction[J], Journal of Central South University of Technology(English Edition), 2000, 7(1): 4–6.

Author information

Authors and Affiliations

Additional information

Foundation item: The National Advanced Materials Committee(No. 715-012-060)

Biography of the first author: CAO Shun-hua, associate professor, born in 1965, majoring in warm compaction and advanced technique for fabricating nano cemented carbide and W-Cu composite.

Rights and permissions

About this article

Cite this article

Cao, Sh., Qu, Xh., Zhang, Lh. et al. Possibility of utilizing water-atomized Fe-Ni-Mo steel powder as base materials for warm compaction process. J Cent. South Univ. Technol. 8, 219–223 (2001). https://doi.org/10.1007/s11771-001-0058-8

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11771-001-0058-8