Abstract

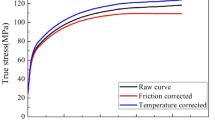

The flow stress behavior of Cu13Zn alloy was investigated by compression tests carried out at 650 °C, 700 °C, 750 °C, 850 °C, and constant strain rates of 0.05 s−1, 0.1 s−1, 0.5 s−1, 1 s−1, 5 s−1, respectively. The results show that the flow stress increases with the increase of strain and reaches a steady-state stress, and the saturated stress (σ s) increases with the increase of the strain rate and the decrease of temperature. Flow stress curves of the alloy deformed at elevated temperatures can be simulated effectively by the model proposed by Zhou and Clode, and the flow stress is described as a function of strain, strain rate and temperature. Material constants values are: Q=270.43 kJ/mol, α=0.020 94, A=1.747×1011 s−1 and n=3.549 mm2·N−1, the deformation mechanisms of the alloy are self-diffusion and dynamic recovery.

Similar content being viewed by others

References

Verlinden B, Shadi A, Delaey L. A generalized constitutive equation for an AA6060 aluminum alloy[J]. Scripta Materialia, 1993, 28(11): 1441–1146.

Braga H C, Barbosa R, Jurgen Breme. Hot strength of Ti and Ti6A14V deformed in axial compression[J]. Scripta Materialia, 1993, 28(8): 979–983.

ZHOU M, Clode M P. A constitutive model and its identification for deformation characterized by dynamic recovery[J]. ASME Journal of Engineering Materials and Technology, 1997, 119(1): 138–142.

Gronostajski Z J. Model describing the characteristic values of flow stress and strain of brass M63 and aluminum bronze BA93[J]. J Mater Process Technol, 1998, 78(1): 84–89.

Sheppard T, Norley J. Deformation characteristics of Ti6Al4V[J]. Mater Sci Technol, 1988, 4(10): 903–908.

Rao K P, Hawbolt E B. Development of constitutive relationships using compression testing of a medium carbon steel[J]. ASME Journal of Engineering Materials and Technology, 1992, 114(1), 116–123.

Sellars M, Tegart McG W J. La relation entre la résistance et la structure dans la déformation à chaud[J]. J Mem Sci De Metall, 1966, 63(9): 731–746.

Author information

Authors and Affiliations

Additional information

Biography of the first author: LI Luo-xing, doctoral student, born in 1968, majoring in materials engineering.

Rights and permissions

About this article

Cite this article

Li, Lx., Peng, Ds., Luo, Fh. et al. Flow stress behavior of Cu13Zn alloy deformed at elevated temperature. J Cent. South Univ. Technol. 7, 198–200 (2000). https://doi.org/10.1007/s11771-000-0053-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-000-0053-5