Abstract

A wide spectrum of triacylglyceride (TG) oils were decomposed in batch lab and continuous pilot-scale reactors to generate an extensive database, which was then used to construct a model to predict the detailed composition of products generated during non-catalytic cracking. The model was then coupled with additional simulated process steps to determine the yields of transportation products and other chemical co-products meeting specifications of their petroleum analogs as validated with laboratory testing. A statistical study was then performed to use the model to analyze the impact that changes in TG oil composition have upon target product yields. In this study, the model was used to simulate a viable suite of products for every TG oil analyzed. The model predicts minor differences in the ratio of products from various different fatty acid compositions. For example, it was found that stearic (C18:0), oleic (C18:1), and erucic (C22:1) acids show a positive effect on fuel yields. By contrast, palmitic (C16:0), linoleic (C18:2), and linolenic (C18:3) acids have negative impacts on fuel yields. From these results, a hypothetical “ideal” TG oil was constructed. This oil turns out to have a composition that is very close to the composition of high oleic sunflower oil.

Similar content being viewed by others

References

Sharma Y, Singh B, Upadhyay S (2008) Advancements in the development and characterization of biodiesel: a review. Fuel 87:2355–2373

Brown R (2007) Hybrid thermochemical/biological processing of biomass. Appl Biochem Biotechnol 137:947–956

Thegarid N, Fogassy G, Schuurman Y, Mirodatos C, Stefanidis S, Iliopoulou EF, Kalogiannis K, Lappas A (2014) Second-generation biofuels by co-processing catalytic pyrolysis oil in FCC Units. Appl Catal B Environ 145:161–166

Saidi M, Samimi F, Karimipourfard D, Nimmanwudipong T, Gates BC, Rahimpour MR (2014) Upgrading of lignin-derived bio-oils by catalytic hydrodeoxygenation. Energy Environ Sci 7:103–129

Brooks B (2013) Eighty percent CO2 reduction targeted by a joint Audi-Joule fuel program. Autom Ind 193

Woods P (2009) Algenol Biofuels’s direct to ethanol technology. Proceedings of the AIChE 2009 Annual Meeting

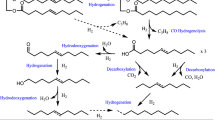

Kubátová A, Šťávová J, Seames W, Luo Y, Sadrameli M, Linnen M, Baglayeva G, Smoliakova I, Kozliak E (2012) Triacylglyceride thermal cracking: pathways to cyclic hydrocarbons. Energy Fuels 26:672–685

Klingshirn CD, DeWitt M, Striebich R, Anneken D, Shafer L, Corporan E, Wagner M, Brigalli D (2012) Hydroprocessed renewable jet fuel evaluation, performance, and emissions in a T63 turbine engine. J Eng Gas Turbines Power 134:051506

Li L (2008) Cyclization; catalytic cracking; anaerobic fermentation. United States patent US7691159 B

Eber K (2013) Can “drop-in” biofuels solve integration issues? Continuum Magazine, 5, http://www.nrel.gov/continuum/sustainable_transportation/biofuels.html. Accessed 31 Aug 2016

ASTM (2011) D975-11, standard specification for diesel fuel oils, ASTM International: West Conshohocken, PA

ASTM (2011) D1655-11b, standard specification for aviation turbine fuels., ASTM International: West Conshohocken, PA

Chew TL, Bhatia S (2008) Catalytic processes towards the production of biofuels in a palm oil and oil palm biomass-based biorefinery. Bioresour Technol 99:7911–7922

Linnen M, Seames W, Kubátová A, Menon S, Alisala K, Hash S (2014) Evaluation of microbial triglyceride oil purification requirements for the Celtherm process, an efficient biochemical pathway to renewable fuels and chemicals. Bioprocess Biosyst Eng 37:2121–2129

Kozliak E, Mota R, Rodriguez D, Overby P, Kubátová A, Stahl D, Niri V, Ogden G, Seames W (2013) Non-catalytic cracking of jojoba oil to produce fuel and chemical by-products. Ind Crops Prod 43:386–392

Asomaning J, Mussone P, Bressler C (2014) Two-stage thermal conversion of inedible lipid feedstocks to renewable chemicals and fuels. Bioresour Technol 158:55–62

Alhroub I, Shen W, Yan J, Sulkes M (2015) Thermal cracking of triacylglycerols: molecular beam studies. J Anal Appl Pyrol 115:24–36

Bosquez N (2012). High grade carbon from crop oil tars, masters Thesis, University of North Dakota, August 2012

Shahidi F (1999) Bailey’s industrial oil & fat products, 6th edn. Wiley, Hoboken, NJ, 2005, ISBM-10: 0471385492

ASTM (2008) D5134-98 Standard test method for detailed analysis of petroleum naphthas through n-nonane by capillary gas chromatography. ASTM International, West Conshohocken

ASTM (2007) D5307-97 Standard test method for determination of boiling range distribution of crude petroleum by gas chromatography. ASTM International, West Conshohocken

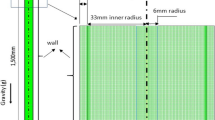

Sander B. (2014) A study of bench scale, pressurized, continuous flow thermal cracking of crop oil, University of North Dakota Masters Thesis

Seames W (2010) Algae oil conversion to JP-8 aviation fuel”, final report, Army Research Office, Grant #W911Nf-09-1-0571

Seames W, Luo Y, Ahmed I, Aulich T, Kubátová A, Šťávová J, Kozliak E (2010) The thermal cracking of canola and soybean methyl esters: improvement of cold flow properties. Biomass Bioenergy 34:939–946

Šťávová J, Beránek J, Nelson EP, Diep B, Kubátová A (2011) Limits of detection for the determination of mono- and dicarboxylic acids using gas and liquid chromatographic methods coupled with mass spectrometry. J Chromatogr B 879:1429–1438

Sťávová J, Stahl D, Seames W, Kubátová A (2012) Method development for the characterization of biofuel intermediate products using gas chromatography with simultaneous mass spectrometric and flame ionization detections. J Chromatogr A 1224:79–88

ASTM (2003) D1298-99 standard test method for density, relative density (specific gravity), or API gravity of crude petroleum and liquid petroleum products by hydrometer method. ASTM International, West Conshohocken

ASTM (2011) D974-11 standard test method for acid and base number by color-indicator titration. ASTM International, West Conshohocken

ASTM (2005) D5972-05 standard test method for freezing point of aviation fuels (automatic phase transition method). ASTM International, West Conshohocken

ASTM (2005) D3828-05 standard test methods for flash point by small scale closed cup tester. ASTM International, West Conshohocken

ASTM (2005) D4809-00 standard test method for heat of combustion of liquid hydrocarbon fuels by bomb calorimeter (precision method). ASTM International, West Conshohocken

Lawson J, Erjavec J. (2000) Modern statistics for engineering and quality improvement, Duxbury, p 810

Palanisamy S, Gevert B (2016) Study of non-catalytic thermal decomposition of triglyceride at hydroprocessing condition. Appl Therm Eng 107:301–310

Braegelmann M, Azure A, Stahl D, Kubátová A, Seames W, Tande B (2011) Extraction of short chain fatty acids from noncatalytically cracked triacylglycerides with aqueous amines. Sep Sci Technol 46(14):2167–2173

Gandhi S, Kadrmas J, Šťávová J, Kubátová A, Muggli D, Seames W, Tande B (2012) Extraction of short chain fatty acids from noncatalytically cracked triacylglycerides with water and aqueous sodium hydroxide. Sep Sci Technol 47(1):66–72

Kadrmas C, Khambete M, Kubátová A, Kozliak E, Seames W (2015) Optimizing the production of renewable aromatics via crop oil catalytic cracking. Processes 3:222–234

Jones B, Linnen M, Tande B, Seames W (2015) A renewable process for the production of vinyl acetate monomer. Processes 3:619–633

Acknowledgements

Funding for this work was received from the North Dakota Department of Commerce Centers of Excellence program via the SUNRISE BioProducts Center of Excellence and Bayer Crop Science. Our thanks to Dr. Burton Johnson, NDSU Plant Sciences and Dr. Russ Gesch, USDA-ARL research agronomist for supplying crambe and camelina seeds.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

11746_2016_2944_MOESM1_ESM.docx

ChemCAD components selected for the RCC (used in simulation, regression, and analysis). Supplementary Table 1 (DOCX 19 kb).

11746_2016_2944_MOESM2_ESM.docx

Coefficients and significance for the regression of OLP composition vs. reaction conditions. Supplementary Table 2 (DOCX 47 kb).

11746_2016_2944_MOESM3_ESM.docx

Coefficients and significance for the regression of OLP composition vs. feedstock fatty acid composition. Supplementary material 3 (DOCX 50 kb).

11746_2016_2944_MOESM5_ESM.docx

Example fuel property reports generated by the study simulation model for a) diesel no. 1 from HO85 canola oil and b) jet fuel from HE Brassica oil. Supplementary Figure 5 (DOCX 16 kb).

11746_2016_2944_MOESM6_ESM.tif

The OLP composition summary from the non-catalytic cracking of each study TG oil: a) canola85, b) high erucic acid brassica, c) camelina, d) crambe, e) cottonseed, f) linseed, g) refined corn oil, and h) crude corn oil. Supplementary Figure 6 (TIFF 1268 kb).

11746_2016_2944_MOESM7_ESM.tif

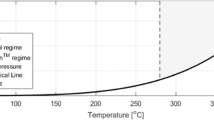

The OLP composition summary from the continuous non-catalytic cracking of soybean oil at various operating conditions: a) 400 C reaction temperature, 400 psig reaction pressure, 3.08 hr residence time, b) 420 C, 400 psig, 3.08 hr, c) 400 C, 400 psig, 1.76 hr, d) 420 C, 400 psig, 1.76 hr, e) 400 C, 200 psig, 3.08 hr, f) 420 C, 200 psig, 3.08 hr, g) 400 C, 200 psig, 1.76 hr, and h) 420 C, 200 psig, 1.76 hr. Supplementary Figure 7 (TIFF 979 kb).

11746_2016_2944_MOESM8_ESM.tif

The fatty acid composition summary for untested TG oils and for a “best” TG oil, denoted here as “fantasy canola”. Supplementary Figure 8 (TIFF 100 kb).

About this article

Cite this article

Seames, W., Linnen, M., Sander, B. et al. The Impact of Fatty Acid Composition on Transportation Fuel Yields via the Non-Catalytic Cracking of Triacylglyceride Oils. J Am Oil Chem Soc 94, 497–509 (2017). https://doi.org/10.1007/s11746-016-2944-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-016-2944-0