Abstract

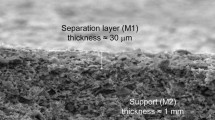

Vegetable oil extraction, as performed today by the oilseed-crushing industry, usually involves solvent extraction with commercial hexane. After this step, the vegetable oil–hexane mixture (miscella) must be treated to separate its components by distillation. If solvent-resistant membranes with good permeation properties can be obtained, membrane separation may replace, or be used in combination with, conventional evaporation. Two tailor-made flat composite membranes, poly(vinylidene fluoride) (PVDF–Si and PVDF–CA) and a commercially available composite membrane (MPF-50), were used to separate a crude sunflower oil–hexane mixture. The effects of temperature, cross-flow velocity (v), transmembrane pressure (Δp), and feed oil concentration (C f) on membrane selectivity and permeation flux were determined. The PVDF–Si membrane achieved the best results, being stable in commercial hexane and having promising permselectivity properties for separation of vegetable oil–hexane miscella. Improved separation performance was obtained at C f = 25%, Δp = 7.8 bar, T = 30 °C, and v = 0.8 m s−1; a limiting permeate flux of 12 Lm−2 h−1 and 46.2% oil retention were achieved. Low membrane fouling was observed under all the experimental conditions studied.

Similar content being viewed by others

References

Woerfel JB (1995) Extraction. In: Erikson DR (ed) Practical handbook of soybean processing and utilization. AOCS Press (Champaign, IL) and United Soybean Board, St. Louis, pp 85–89

Koseoglu SS, Lawhon JT, Lusas EW (1990) Membrane processing of crude vegetable oils: pilot plant scale removal of solvent from oil miscellas. J Am Oil Chem Soc 67:315–322

Coutinho CM, Chiu MC, Basso RC, Ribeiro APB, Gonçalves LAG, Viotto LA (2009) State of the art of the application of membrane technology to vegetable oils: a review. Food Res Int 42:536–550

Van der Bruggen B, Geens J, Vandercasteele C (2002) Fluxes and retention for nanofiltration with solvent stable polymeric membrane in water, ethanol and n-hexane. Chem Eng Sci 57:2511–2518

Stamatialis DF, Stafie N, Buadu K, Hempenius M, Wessling M (2006) Observations on the permeation performance of solvent resistant nanofiltration membranes. J Membr Sci 279:424–433

Iwama A (1989) New process for purification soybean oil by membrane separation and economical evaluation of process, in Proceedings of The World Conference on Biotechnology for the Fats and Oils Industry, Am Oil Chem Soc, Champaign, IL

Pagliero C, Ochoa N, Marchese J, Mattea M (2001) Degumming of crude soybean oil by ultrafiltration using polymeric membranes. J Am Oil Chem Soc 78:793–796

Raman LP, Cheryan M, Rajagopalan N (1996) Deacidification of soybean oil by membrane technology. J Am Oil Chem Soc 73:219–224

Kwiatkowski JR, Cheryan M (2005) Recovery of corn oil from ethanol extracts of ground corn using membrane technology. J Am Oil Chem Soc 82:221–227

Wu JC, Lee E (1999) Ultrafiltration of soybean oil–hexane extract by porous ceramic membranes. J Membr Sci 154:251–259

Ribeiro APB, Moura JMLN, Gonçalves LAG, Petrus JCC, Viotto LA (2006) Solvent recovery from soybean oil–hexane miscella by polymeric membranes. J Membr Sci 282:328–336

Raman LP, Cheryan M, Rajagopalan N (1996) Solvent recovery and partial deacidification of vegetable oil by membrane technology. Lipid 98:10–14

Machado DR, Hasson D, Semita R (1999) Effect of solvent properties on permeate flow through nanofiltration membranes. Part 1. Investigation of parameters affecting solvent flux. J Membr Sci 163:93–102

Darvishmanesh S, Buekenhoudt A, Degrèvea J, Van der Bruggen B (2009) General model for prediction of solvent permeation through organic and inorganic solvent resistant nanofiltration membranes. J Membr Sci 334:43–49

Acknowledgments

The authors thank the National Research Council of Argentina (CONICET) and the National Agency for Scientific Promotion (ANPCYT) for their financial assistance.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Pagliero, C., Ochoa, N.A., Martino, P. et al. Separation of Sunflower Oil from Hexane by Use of Composite Polymeric Membranes. J Am Oil Chem Soc 88, 1813–1819 (2011). https://doi.org/10.1007/s11746-011-1839-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-011-1839-3