Abstract

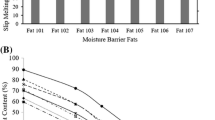

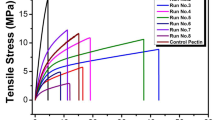

The effect of three cooling rates (rapid, intermediate and slow CR) on the moisture barrier properties and on the physical state of acetylated and high melting point hydrophobic self-supported moisture barriers has been investigated. The selected CR were representative of industrial processing conditions and the selected barrier materials of common effective GRAS substances (acetomonopalmitin, white beeswax, two commercial blends of beeswax and acetylated glycerides and a blend of palmitic/stearic acids). Variations of CR affected crystallisation kinetics, SFC in an extend depending on the fat chemical composition and degree of undercooling, crystal size and ratio of polymorphs present in the materials. It did not have major influence on the contact angles with water measured at the surface of the materials and on the mass–volume area properties of the material. The resultant effect on the macroscopic moisture barrier properties of the materials were evaluated using water vapour permeability (WVP) measurements. The CR had no significant effect on the WVP, except for one blend of acetylated fat and beeswax for which a slow CR may have favoured the healing of imperfections. The variations of WVP between all materials and CRs were mainly attributed to variation in materials polarity using multivariable analysis.

Similar content being viewed by others

Abbreviations

- AMP:

-

Acetomonopalmitin

- CR:

-

Cooling rate

- d app :

-

Apparent density

- d true :

-

True density

- GRAS:

-

Generally recognised as safe

- MP:

-

Melting point

- P/S:

-

Palmitic/stearic acid blend

- RH:

-

Relative humidity

- SEM:

-

Scanning electron microscopy

- SFC:

-

Solid fat content

- W/A:

-

Wax/acetic acid ester of mono and diglycerides

- WVP:

-

Water vapour permeability

- XRD:

-

X-ray diffraction

- A :

-

Area of exposed film

- α, β′, β:

-

Hexagonal, orthorhombic and triclinic subcell lateral packings

- d :

-

Interplanar crystal lattice distance

- Δs :

-

Slope of water weight versus time

- e :

-

The film thickness

- ε :

-

Porosity

- k :

-

Avrami constant

- M :

-

Molecular mass of water

- n :

-

Avrami exponent or index of crystallisation

- p°:

-

the saturating water vapour pressure of water at constant considered temperature

- a w :

-

Water activity

References

McHugh TH, Krochta JM (1994) Permeability properties of edible films. In: Krochta JM, Baldwin EA, Nisperos-Carriedo MO (eds) Edible films and coatings to improve food quality. Technomic Publishing Company, Lancaster, pp 139–187

Shellhammer TH, Rumsey TR, Krochta JM (1997) Viscoelastic properties of edible lipids. J Food Eng 33:305–320

Morillon V, Debeaufort F, Blond G, Capelle M, Voilley A (2002) Factors affecting the moisture permeability of lipid-based edible films: a review. Crit Rev Food Sci Nutr 42:67–89

Bourlieu C, Guillard V, Powell H, Vallès-Pàmies B, Guilbert S, Gontard N (2009) Edible moisture barriers: how to assess of their potentials and limits in food products shelf-life extension? Crit Rev Food Sci Nutr 49:474–499

Guillard V, Guillbert S, Bonazzi C, Gontard N (2004) Edible acetylated monoglyceride films: effect of film-forming technique on moisture barrier properties. J Am Oil Chem Soc 81:1053–1058

Bourlieu C, Ferreira M, Barea B, Guillard V, Villeneuve P, Guilbert S, Gontard N (2009) Moisture barrier and physical properties of acetylated derivatives with increasing acetylation degree. Eur J lipid Sci Techn 111(5):489–498

Martin-Polo M, Mauguin C, Voilley A (1992) Hydrophobic films and their efficiency against moisture transfer. 1. Influence of the film preparation technique. J Agric Food Chem 40:407–412

Lovegren NV, Feuge RO (1954) Permeability of acetostearin products to water vapor. J Agric Food Chem 2:558–563

Landmann W, Lovegren NV, Feuge RO (1960) Permeability of some fat products to moisture. J Am Oil Chem Soc 37(1):1–4

Kester JJ, Fennema O (1989) The influence of polymorphic form on oxygen and water-vapor transmission through lipid films. J Am Oil Chem Soc 66:1147–1153

Donhowe IG, Fennema O (1993) Water-vapor and oxygen permeability of wax films. J Am Oil Chem Soc 70:867–873

Sato K (2001) Crystallization behaviour of fats and lipids—a review. Chem Eng Sci 56:2255–2265

Fox RC (1958) The relationship of wax crystal structure to the water vapor transmission rate of wax films. TAPPI 41:283–289

Kester JJ, Fennema O (1989) Tempering influence on oxygen and water vapor transmission through a stearyl alcohol film. J Am Oil Chem Soc 66:1154–1157

Martini S, Kim DA, Ollivon M, Marangoni AG (2006) Structural factors responsible for the permeability of water vapor through fat barrier films. Food Res Int 39:550–558

Martini S, Kim DA, Ollivon M, Marangoni AG (2006) The water vapor permeability of polycrystalline fat barrier films. J Agric Food Chem 54:1880–1886

Campos R, Narine SS, Marangoni AG (2002) Effect of cooling rate on the structure and mechanical properties of milk fat and lard. Food Res Int 35:971–981

Ollivon M, Perron R (1992) Chapitre IV. Propriétés chimiques des corps gras. In: Karleskind A (ed) Manuel des corps gras. Tec & Doc, Lavoisier, Paris, pp 433–529

Burton Z, Bhushan B (2006) Surface characterization and adhesion and friction properties of hydrophobic leaf surfaces. Ultramicroscopy 106:709–719

Morillon V, Debeaufort F, Capelle M, Blond G, Voilley A (2000) Influence of the physical state of water on the barrier properties of hydrophilic and hydrophobic films. J Agric Food Chem 48:11–16

Lide DR (1972) Handbook of chemistry and physics. 53rd edn. CRC (Chemical Rubber Company) Press, Cleveland

Guillard V, Broyart B, Bonazzi C, Guilbert S, Gontard N (2003) Preventing moisture transfer in a composite food using edible films: Experimental and mathematical study. J Food Sci 68:2267–2277

Acknowledgments

We gratefully acknowledge: Nestlé Research Centre and the Product Technology Centre of York for giving financial and scientific support to this work, the Lipids Technology Unit (CIRAD) of UMR IATE for its help concerning the SFC measurements, the ‘Service Commun Réseau de Rayons X et γ’ (University Montpellier II) where X-Ray diffraction measurements were performed, D. Cot of the ‘Institut Européen des Membranes’ for SEM observations, the ‘Techtonophysique Laboratoire’ (University Montpellier II) for authorised use of the polarised light microscope.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Bourlieu, C., Guillard, V., Ferreira, M. et al. Effect of Cooling Rate on the Structural and Moisture Barrier Properties of High and Low Melting Point Fats. J Am Oil Chem Soc 87, 133–145 (2010). https://doi.org/10.1007/s11746-009-1476-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-009-1476-2