Abstract

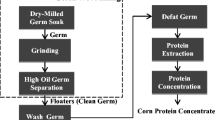

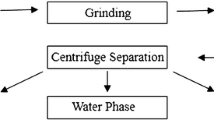

The increase in ethanol production from corn has prompted development of processes to separate corn germ. The corn germ co-product would be a source of corn oil if a practical oil separation process were also developed. We carried out bench-scale corn-germ-pressing experiments to determine the maximum potential oil recovery which were then used to estimate commercial germ crushing costs. Corn germ was preheated in a microwave oven and oil was then extracted with a bench-scale press. Preheating the germ was necessary to obtain good oil yields. The uniform heating of the microwave oven more closely resembles compressive heating of commercial scale presses than does oven heating. Three different microscopic techniques were used to examine the effects of microwave and conventional-oven heating on corn germ. Microscopy revealed that microwave heating heated oil in the germ more quickly than the other components of the germ. Heating by both methods destroyed lipid body membranes and oil coalesced and pooled. Less oil could be pressed from germ initially containing 3–6% moisture than germ containing 15–20% moisture. Maximum oil recovery of about 65% was obtained for all germs tested when the optimum press temperature and germ feed moisture were used.

Similar content being viewed by others

References

Singh N, Cheryan M (1998) Extraction of oil from corn distillers dried grains with solubles. Trans ASAE 41:1775–1777

Bryan T (2005) Factor of differentiation. Ethanol Producer Mag 11:48–53

Singh VJ, Eckhoff S (1996) Effect of soak time, soak temperature and lactic acids on germ recovery parameters. Cereal Chem 73:716–720

Singh VJ, Johnston DB, Naidu K, Rausch KD, Belyea RL, Tumbleson ME (2005) Comparison of modified dry-grind corn processes for fermentation characteristics and DDGS composition. Cereal Chem 82:187–190

Johnston D, McAloon AJ, Moreau RA, Hicks KB, Singh VJ (2005) Composition and economic comparison of germ fractions from modified corn processing technologies. J Am Oil Chem Soc 82:603–608

Giguere RJ (1993) Grain milling and degermination process. US Patent 5,250,313

Moreau RA, Johnston DB, Hicks KB (2005) The influence of moisture content and cooking on the screw pressing and pre-pressing of corn oil from corn germ. J Am Oil Chem Soc 82:851–854

Singh K, Wiesenborn D, Kangas N, Tostenson K (2003) Screw pressing characteristics of dehulled crambe seed. Trans ASAE 47:199–204

Zheng Y, Wiesenborn DP, Tostenson K, Kangas N (2005) Energy analysis in the screw pressing of whole and dehulled flaxseed. J Food Eng 66:193–202

Bredeson DK (1978) Mechanical extraction. J Am Oil Chem Soc 55:762–764

Barringer SA, Davis EA, Gordon J, Ayappa KG, Davis HT (1994) Effect of Sample size on the microwave-heating rate: oil versus water. AIChE J 40:1433–1439

Mohsenin NN (1980) Thermal properties of foods and agricultural materials. Gordon and Breach, New York

Moreau RA, Powell MJ, Singh VJ (2003) Pressurized liquid extraction of polar and nonpolar lipids in corn and oats with hexane, methylene chloride, isopropanol and ethanol. J Am Oil Chem Soc 80:1063–1067

Association of Official Analytical Chemists (1998) In: official methods of analysis, 16th edn, vol 1:4.2.08. AOAC, Arlington

American Association of Cereal Chemists (1995) Methods 46-30 and 44-19. In: Approved Methods of the AACC, 9th edn. AACC, St. Paul

Fowler SD, Greenspan P (1985) Application of Nile Red, a fluorescent hydrophobic probe, for the detection of neutral lipid deposits in tissue sections: comparison with oil red O. J Histochem Cytochem 33:833–836

Richardson KC, Jarett L, Finke EH (1960) Embedding in epoxy resins for ultrathin sectioning in electron microscopy. Stain Technol 35:313–325

Rajagopalan S, Ponnampalam E, McCalla D, Stowers M (2005) Enhancing profitability of dry mill ethanol plants. Appl Biochem Biotechnol 120:37–50

Barringer SA, Ayappa KG, Davis EA, Davis HT, Gordon J (1995) Power absorption during microwave heating of emulsions and layered systems. J Food Sci 60:1132–1136

Noureddini H, Teoh BC, Clements LD (1992) Viscosities of vegetable oils and fatty acids. J Am Oil Chem Soc 69:1189–1191

Acknowledgments

The authors thank Michael F. Dallmer for expert technical assistance, W.J. Duensing of Bunge North America who gave the authors valuable insight into the nature of the dry-milling industry, R.L. Stroup, who shared his knowledge of soybean mill operations and costs.

Author information

Authors and Affiliations

Corresponding author

Additional information

Mention of trade names or commercial products in this publication is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the US Department of Agriculture.

About this article

Cite this article

Dickey, L.C., Cooke, P.H., Kurantz, M.J. et al. Using Microwave Heating and Microscopy to Estimate Optimal Corn Germ Oil Yield with a Bench-Scale Press. J Amer Oil Chem Soc 84, 489–495 (2007). https://doi.org/10.1007/s11746-007-1051-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-007-1051-7