Abstract

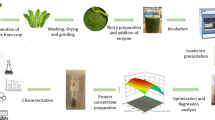

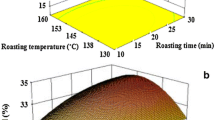

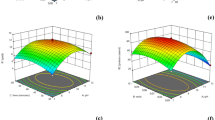

An aqueous enzymatic extraction method was developed to obtain free oil and protein hydrolysates from dehulled rapeseeds. The rapeseed slurry was treated by the chosen combination of pectinase, cellulase, and β-glucanase (4:1:1, v/v/v) at concentration of 2.5% (v/w) for 4 h. This was followed by sequential treatments consisting of alkaline extraction and an alkaline protease (Alcalase 2.4L) hydrolysis to both produce a protein hydrolysate product and demulsify the oil. Response surface methodology (RSM) was used to study and optimize the effects of the pH of the alkaline extraction (9.0, 10.0 and 11.0), the concentration of the Alcalase 2.4L (0.5, 1.0 and 1.5%, v/w), and the duration of the hydrolysis (60, 120, and 180 min). Increasing the concentration of Alcalase 2.4L and the duration of the hydrolysis time significantly increased the yields of free oil and protein hydrolysates and the degree of protein hydrolysis (DH), while the alkaline extraction pH had a significant effect only on the yield of the protein hydrolysates. Following an alkaline extraction at pH 10 for 30 min, we defined a practical optimum protocol consisting of a concentration of 1.25–1.5% Alcalase 2.4L and a hydrolysis time between 150 and 180 min. Under these conditions, the yields of free oil and protein hydrolysates were 73–76% and 80–83%, respectively. The hydrolysates consisted of approximately 96% of peptides with a MW less than 1500, of which about 81% had a MW less than 600 Da.

Similar content being viewed by others

References

FAO/WHO/UNU (2002) Agricultural bulletin board on data collection, dissemination and quality of statistics. World Health Organization, Geneva

Henryk N (1990) Rapeseed. Elsevier, Amsterdam

Marlowe IT, Giddings TJ, Richardson SJ, Stentiford A (1991) UK industry and ozone pollution from volatile organic compound emissions. Warres Spring Laboratory, Report 878. The Environmental Technology Executive Agency of the Department of Trade and Industry, London

Domínguez H, Nunez MJ, Lema JM (1994) Enzymatic pretreatment to enhance oil extraction from fruits and oilseeds: a review. Food Chem 49:271–286

Rosenthal A, Pyle DL, Niranjan K (1996) Aqueous and enzymatic processes for edible oil extraction. Enzyme Microb Technol 19:402–420

Cater CM, Rhee KC, Hagenmaier RD, Mattil KF (1974) Aqueous extraction—an alternative oilseed milling process. J Am Oil Chem Soc 51:137–141

Olsen HAS (1981) Method of producing soy protein hydrolysate from fat-containing soy material, and soy protein hydrolysate. U.S. Patent 4,324,805, Washington D.C.

Yust MM, Pedroche J, Megias C, Calle JG, Alaiz M, Millan F, Vioque J (2004) Rapeseed protein hydrolysates: a source of hiv protease peptide inhibitors. Food Chem 87:387–392

Lanzani A, Petrini MC, Cozzoli O, Gallavresi P, Carola C, Jacini G (1975) On the use of enzymes for vegetable-oil extraction. A preliminary report. Riv Ital Sostanze Grasse L11:226–229

Fullbrook PD (1983) The use of enzymes in the processing of oilseeds. J Am Oil Chem Soc 60:476–478

Jensen SK, Olsen HS, Sørensen H (1990) Aqueous enzymatic processing of rapeseed for production of high quality products. In: Shahidi F (ed) Canola and rapeseed: production, chemistry, nutrition and processing technology. Van Nostrand Reinhold, New York, pp 331–344

Myers RH, Montgomery DC (1995) Response surface methodology: process and product optimization using designed experiments. John Wiley & Sons, Chichester

Jens AN (1986) Enzymatic hydrolysis of food proteins. Elsevier, London

Doi E, Shibata D, Matoba T (1981) Modified colorimetric ninhydrin method for peptidase assay. Anal Biochem 118:173–184

Association of official analytical chemists (AOAC) (1995). Official methods of analysis, 16th edn. AOAC International, Gaithersburg

Dubois MW, Anglemier AF, Montgomery MW, Davidson WD (1972) Effect of proteolysis on the emulsification characteristics of bovine skeletal muscle. J Food Sci 37:27–28

Smith DM, Brekke CJ (1984) Functional properties of enzymatically modified beef heart protein. J Food Sci 49:1525–1528

Xu L, Diosady LL (1994) The production of Chinese rapeseed protein isolates by membrane processing. J Am Oil Chem Soc 71:935–939

Klockeman DM, Toledo R, Sims KA (1997) Isolation and characterization of defatted canola meal protein. J Agric Food Chem 45:3867–3870

Cheison SC, Wang Z, Xu SY (2006) Hydrolysis of whey protein isolate in a tangential flow filter membrane reactor-I: characterisation of permeate flux and product recovery by use of multivariate data analysis. J Membrane Sci 283:45–56

Tessier B, Schweizer M, Fournier F, Framboisier X, Chevalot I, Vanderesse R, Harscoat C, Marc I (2005) Prediction of the amino acid composition of small peptides contained in a plant protein hydrolysate by LC-MS and CE-MS. Food Res Int 38:577–584

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Zhang, S.B., Wang, Z. & Xu, S.Y. Optimization of the Aqueous Enzymatic Extraction of Rapeseed Oil and Protein Hydrolysates. J Amer Oil Chem Soc 84, 97–105 (2007). https://doi.org/10.1007/s11746-006-1004-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-006-1004-6