Abstract

The ultrasound contrast agents Echovist® and Levovist® (Bayer AG, Schering AG, Germany) are based on the release of gas bubbles from milled α-d-galactose. In diagnostic ultrasound, for this class of contrast agents, there is a need for prolonged contrast duration. To investigate if new carbohydrate compositions could prolong the lifetime of the gas bubbles, α-d-galactose was mixed with other carbohydrates or amphiphiles with varying log P. Acoustic attenuation vs. time (390 s) area under the curve (A 390) and bubble half-time (t½) were used as measures of prolonged lifetime of gas bubbles. The products, to which 0.1% of a lipophilic carboxylic acid (5β-cholanic acid, behenic acid, and melissic acid) has been added, showed more than 5, 7 and 11 times enhancement of A 390, respectively, compared with the reference compound 2 (RC2) corresponding to the commercial product Levovist®. The half-time t ½ of the same compounds was prolonged more than 6 times compared with RC2. A partial least square (PLS) statistical analysis confirmed that, for additives, high log P carboxylic acids lead to the highest A 390. The present results bear a promise of products with a more persistent in vivo ultrasound contrast effect than the commercially available agents.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Gas bubbles in the micrometer range are ideal contrast agents for ultrasound imaging because of their high compressibility and low density, giving excellent reflectance of ultrasound waves (acoustic backscatter) [1]. Ultrasound contrast signals from free gas bubbles in vivo in the human heart were first observed in 1968 after direct intracardiac injection [2]. Short bubble lifetime urged development of more stable agents giving more persistent contrast on the arterial side after intravenous injection and passage through the lung capillaries. The ultimate goal is to generate contrast in the heart muscle (myocardium). Suspensions of solid particles, emulsified liquid droplets, free and encapsulated gases or liquids [3] have been proposed as ultrasound contrast agents (USCA). Efficient USCA may comprise micron-sized bubbles stabilized by a thin, potentially biodegradable flexible membrane consisting of polymers [4] or phospholipids [5]. However, carbohydrate-based gas-releasing systems, generating free gas bubbles after intravenous injection of a particle suspension, eliminate the challenge of developing a stabilized bubble suspension as a drug product, with demands of long term shelf stability. In the commercially available agent SHU 454 (Echovist®, Schering AG, Berlin), milled, particulate water-soluble α-d-galactose acts as a precursor for gas bubbles, and is in clinical use in enhanced hystero-sonography [6]. The gas-releasing powder is prepared using ball-milling of commercial α-d-galactose, giving clusters of particles with a mean size of about 40 μm, with air-filled voids between them [7]. Upon dissolution in water, the clusters release the air trapped in the clusters and gas bubbles are generated. The α-d-galactose crystals dissolve in the water phase while acting as short-living nucleation sites for the gas bubbles [7]. Lack of myocardial contrast enhancement (MCE) with SHU 454 in humans led to the improved agent SHU 508 (Levovist®, Schering AG, Berlin), wherein α-d-galactose is milled with 0.1% palmitic acid [8]. However, in spite of more persisting contrast on the arterial side of the heart with SHU 508 [9], it is not in clinical use to study early reduced blood flow in the myocardium using MCE. Since preformed, lyophilized phospholipid-stabilized gas bubbles on the market have been a success [10], the simplicity of the gas-releasing carbohydrate-based products in the form of a dry, particulate, water-soluble precursor of gas bubbles encouraging further research. In the present research, our first aim was to investigate if lifetime of the populations of gas bubbles released could be prolonged, by investigating a broad range of amphiphilic compounds. Our second aim was to investigate if acoustic attenuation vs. time (390 s) area under the curve could be used as a suitable screening tool in this research.

Experimental Section

Materials

Chemicals

Starch was purchased from Reppal PSM 70, Reppe Glykos (Sweden). α-d-Xylose was purchased from BDH (Basel, Switzerland). 1,2-dipalmitoyl-sn-glycero-3-phosphatidylcholine (DPPC) and 1,2-dioleoyl-sn-glycero-3-phosphatidylethanolamine (DOPE) were purchased from Avanti Polar Lipids, USA. Human serum albumin (HSA), sodium dodecyl sulfate (Sodium lauryl sulfate, Na-LS), 2-sulfobutanedioic acid 1,4-bis(2-ethylhexyl) ester sodium salt (Na-docusate), Pluronic® F68 (\( \overline{Mw} \) 8.4 kDa) a very hydrophilic polyoxyethylene polyoxypropylene triblock copolymer (abbreviated HTBCP), sorbitan mono-oleate isomer mixture (Span 80) abbreviated SMO, sorbitan tri-oleate isomer mixture Span 85) abbreviated STO, α-linolenic acid ((Z,Z,Z)-9,12,15-octadecatrienoic acid) and other fatty acids were purchased from Sigma Chemical Company (St. Louis, MO). Tricosa-10,12-diynoic acid was purchased from ABCR GmbH & Co. (Karlsruhe, Germany). Hexadecanedioic acid, α-cyclodextrin, dextran (\( \overline{Mw} \) 20 kD), maltodextrin, glycogen, α-d-galactose and all other chemicals were purchased from Fluka Chemie AG (Buchs, Switzerland) or E. Merck AG (Darmstadt, Germany). Scheme 1 gives the structures of the used compounds except for the oligo and polysaccharides. Deionized water was used throughout the experiments. Chemical structures and names of the compounds used in the present work are given in Scheme 1.

Visual Inspection of the Products After Suspension in the Carrier Liquid

Screening of the rough ability of the products to release gas microbubbles was performed using conventional light microscopy.

Area Under the Curve of Acoustic Attenuation and Bubble Half-Time

A carrier liquid for determining the acoustic attenuation of the products consisted of 10 mL of propylene glycol mixed with 90 mL of 5% dextrose in water. Each product (1.0 g) was dispersed in the carrier liquid (3.0 mL) and gently handshaken for 15 s. The resulting mixture was added to 5% human serum albumin in phosphate buffer (52 mL). The mixture was placed in a measurement cell with a 5 MHz broadband transducer mounted on one side wall, and an ultrasound-reflecting plate on the opposite side of the cell. A pulse-reflection technique measuring the acoustic transmission through the product dispersions was used to calculate the acoustic attenuation taken as the inverse value of the measured acoustic transmission. The acoustic attenuation (dB/cm) was plotted as a function of time for 390 s. Temperature in the measurement cell was 37 ± 1 °C with constant circulation of the liquid. The results were normalized with regards to measurements of a reference consisting of 55 mL of 5% human serum albumin buffer solution. The calculated integral of the area A under the curve of acoustic attenuation vs. time (390 s), was denoted A 390. This parameter expressed the total amount of gas phase in the dispersions up to and including 390 s. Average bubble lifetime was characterized by the half-time (t½) of the acoustic attenuation up to 390 s. Both A 390 and t½ were necessary to decide if persistence of ultrasound contrast effect in vitro was improved for the various formulations compared with the reference standards (defined below).

Particle Size Distribution

The particle size distribution of selected products was analyzed using a Coulter Counter LS 100 or a Malvern Mastersizer light-scattering apparatus by suspending 2 g of the product using a vibrating screen before measuring.

Monitoring of Amphiphiles

The surfactants, phospholipids and fatty acids milled with the carbohydrates were monitored by analyzing the product (1.0 g) in carrier liquid (3 mL) using thin layer chromatography (TLC) and detecting spots using Nile blue fluorescence and copper complexation as described in the literature [11].

log P Values

The concept of hydrophilic-lipophilic balance (HLB) is based on calculations of the ratio of hydrophilic and lipophilic groups in the molecules [12]. However, HLB values approach zero for many of the compounds used in the present study with low water solubility. Therefore calculated log P was found to be a more useful parameter characterizing the amphiphiles used herein. The log P values of the amphiphilic compounds were calculated using the chemist drawing and calculation software ChemBioDraw, version 11.0.1, CambridgeSoft Europe Office, 1 Signet Court, Swanns Road, Cambridge CB5 8LA UK.

Data Analysis

The parameters defined below were used (abbreviations in parentheses) in a partial least squares analysis (PLS) model with A 390 as a response parameter: % (w/w) amphiphilic material added (% amph); calculated log P of the amphiphiles (log P); ionic character in sodium salt form (ionicity: 0 or 1); mean particle size in freshly prepared suspensions (psize); % (w/w) α-d-galactose (%Gal); molecular weight of the amphiphilic additive (LipidMw); degree of unsaturation in the additives as number of double bond equivalents (Unsat: 1–4); number of rings in the chemical structure of the amphiphile (rings); presence of carboxylic acid groups (Carboxyl: 0 or 1). The PLS analysis was performed using the computer program Unscrambler, version 7.01 from CAMO Software AS, Oslo, Norway.

Preparation of Products

All concentrations are given as % w/w in the procedures. Two literature procedures for preparation of carbohydrate-based gas-releasing ultrasound contrast agents [7, 13] were modified to establish the three general preparation procedures below. Ball-milling was performed with a Retsch centrifugal ball-mill in a stainless steel ball-mill having a 50 mL grinding cup and 3 × 20 mm balls for 10 min. All products appeared as white powders after milling.

General Procedure I: Mixtures of Carbohydrates Without Amphiphiles Added, Products 1–4

Products (1) and (2) consisted of commercial qualities of α-d-galactose (1) and α-d-xylose, respectively, that were ball-milled. The α-d-galactose/Starch Mixtures (3a-c) were prepared by mixing α-d-galactose (3.2, 2.0 and 0.8 g) with starch (0.8, 2.0, and 3.2 g, respectively) followed by ball-milling. The α-d-galactose/Dextran (\( \overline{Mw} \) 20 kD) mixtures (4a-b) were prepared by combining 25.8% solutions of α-d-galactose in water (29.2 and 19.4 g) with 25.7% solutions of Dextran in water (9.7 and 19.4 g, respectively). The combined solutions were evaporated to dryness while stirring under reduced pressure (10 Torr, 40 °C) and dried in a desiccator overnight. The products were then ball-milled. Experimental data and results for products 1–4 are given in Table 1.

General Procedure II: α-d-galactose-Based Products with Surfactants (5–11) and Lipophilic Acids (12–19)

For each of the products 5–19, the amphiphilic additives were each dissolved in 96% ethanol or water at 50–78 °C. The resulting solutions were filtered and then added to 1 (24.2 g) under stirring. The resulting mixtures were evaporated to dryness under reduced pressure (10 Torr, 40 °C) and the resulting solid products were dried in a desiccator overnight. The residues were ball-milled to give the final products. Experimental data and results for products 5–19 are given in Tables 2 and 3.

General Procedure III: Palmitic Acid Added to a Mixture of α-d-galactose (1) and Starch (20) and Carbohydrates Other than α-d-galactose (21–24)

For 20, α-d-galactose (1, 12.1 g) was heated to 60 °C and mixed with a 14.3% w/w starch solution in water (35.0 g) before addition of the fatty acid solution. For products 21 and 22, α-d-galactose (1) was replaced by 41.3% w/w solutions (24.2 g) of α-d-xylose and maltodextrin, respectively. For 23 and 24, α-d-galactose (1) was replaced by 22.5% w/w solutions (22.2 g) of glycogen and α-cyclodextrin, respectively. The resulting mixtures were evaporated to dryness under reduced pressure (10 Torr, 40 °C). The resulting solid products were dried in a desiccator overnight and the residues were ball-milled to give the products. Experimental data and results for products 20–24 are given in Table 4.

Results and Discussion

Results

The particle size distributions of the solid products 1–24 were in the range of 1–20 μm (Coulter Counter, data not given). In example, a typical accumulated particle volume distribution of 18b showed that 90% was <4.4 μm and 10% was <0.5 μm, the mean diameter was 2.2 μm and the median diameter was 2.1 μm. Based on visual microscopy observation, the solid particles tended to release air bubble dispersions in the size range of 1–15 μm, with some larger bubbles.

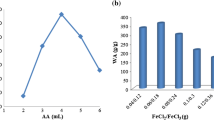

For product comparison, two reference compounds were needed: according to the literature and product descriptions [7, 13, 14], milled α-d-galactose (1) corresponds to the commercial product Echovist® and was chosen as reference product 1 (denoted RC1). According to the literature [8] and public information, the product consisting of α-d-galactose milled with 0.1% palmitic acid (13a) corresponds to the commercial product Levovist®, and was chosen as reference product 2 (denoted RC2). The results of the acoustic characterization expressed as A 390 are given in Tables 1, 2, 3 and 4. The results of the measurement of A 390 after mixing with the carrier liquid are given in Figs. 1, 2, 3, 4 and 5.

Acoustic attenuation (dB/cm) vs. time (390 s) of carbohydrate mixtures without amphiphiles added, compared with the reference standard 1 (RC1), milled α-d-galactose (1). When no amphiphiles are present, mixing of α-d-galactose with polymeric carbohydrates like starch or Dextran with \( \overline{Mw} \) 20 kD only slightly increases A390 compared with RC1

Acoustic attenuation (dB/cm) vs. time (390 s) of different carbohydrates with 0.2% palmitic acid compared with the reference standard 2 (RC2), milled α-d-galactose with 0.2% palmitic acid (13b). Adding palmitic acid to different carbohydrates shows that A 390 of RC2 is superior for the first 100 s compared with the products containing maltodextrin, glycogen and α-cyclodextrin with the same amount of palmitic acid

Acoustic attenuation (dB/cm) vs. time (390 s) of α-d-galactose with 1% of different amphiphiles, surfactants and linolenic acid compared with α-d-galactose containing 1% palmitic acid. The intensity and duration of the acoustic attenuation of all products containing 1% amphiphiles with various log P values, but lacking carboxylic acid functionality, is significantly lower than for RC2

Figures 6 and 7 show the statistical analysis of the results, using A 390 as a response parameter. A high log P, the presence of α-d-galactose and that of a carboxylate group in the amphiphilic molecule correlates positively with A 390. In addition, the PLS analysis reveals some interaction effects between parameters. There is a strong interaction between log P and the presence of a carboxylate group; an interaction between log P and the presence of α-d-galactose is also evident from the analysis.

Discussion

As shown in Figs. 1 and 2, the use of other carbohydrates than α-d-galactose does not improve performance (A 390 and t½) as compared with the α-d-galactose-based reference products RC1 and RC2. The observed significant increase in both A 390 and t½ when α-d-galactose is mixed with 0.1% of β-cholanic acid (19b), behenic acid (16a), and melissic acid (18b) compared with RC2 (Fig. 5), correlates well with the log P values for the acids. The products 16a and 18b show half-time t½ > 500 s compared with t½ = 31 s for RC2 (Table 3). For instance, log P for 5β-cholanic, behenic and melissic acids are calculated to be 7.7, 9.9 and 13.8, respectively. The A 390 values for the corresponding products 19b, 16a and 18b are 1,962, 2,745 and 4,095, respectively. When the amount of these fatty acids is increased to 1% (products 16b, 18c and 19c, Table 3, Fig. 4) the correlation of A 390 and t½ with log P is even more pronounced.

An interesting comparison is the results for the products 13c, 14 and 15, with 1% (w/w) palmitic acid, hexadecanedioic acid and linolenic acid, respectively (Table 3). Both A 390 and t½ are more than 100% higher for 13c compared with 14. The dicarboxylic acid 14 will need to bend its lipophilic chain at the gas–water interface, reducing the lipophilic interaction. For linolenic acid (15), a highly unsaturated carboxylic acid with a log P comparable to palmitic acid, A 390 is at the level of 14 and with a half life of only 79 compared with 107 for 13c (Table 3 and Fig 3). This may be due du the high number of cis double bonds in linolenic acid, giving a non-linear conformation of the lipophilic chain, reducing the hydrophobic interactions between the hydrocarbon chains [15].

The PLS analysis illustrated by the regression coefficient plot (Fig. 6) provides further support for the trends observed in the A 390 plots. An absolute high and stable regression coefficient for many principal components indicates a robust effect of the actual descriptor (Fig. 6). The strongest positive correlation is shown between amphiphiles possessing a carboxylic acid functionality and high log P added to α-d-galactose. This points at fatty acids with a number of carbon atoms >20, in good compliance with the experimental data. These data are further strengthened by the experimental results for amphiphiles with high log P but lacking the carboxyl functionality; all have low A 390 (e.g. the phospholipid-based product 11). M w alone has negligible effect on A 390 as shown by its regression coefficient (Fig. 6). The good correlation between predicted and observed A 390 values (Fig. 7) shows that a suitable model explaining the main effects on A 390 has been established. The reliability of the PLS estimated trends was also tested by regressing various logarithmic transformations of the response having a more uniform variation than the original A 390, and unimportant regression coefficients were successively removed. This process gave similar regression coefficients patterns as shown in Fig. 6 regarding the most important parameters affecting A 390 as well as t½.

Ultrasonic waves are heavily attenuated at gas–water interfaces [1]. It has earlier been reported [16] that a linear correlation between ultrasonic attenuation and interfacial area in a gas–liquid bubble column could be used to estimate the total interfacial area in the system. The same acoustic phenomenon was used in the present study to establish a method to monitor the amount and lifetime of bubble populations generated by milled carbohydrates.

The amphiphiles in the present study with the highest log P are practically insoluble in water [17]. Thus, when the ethanolic solutions of the amphiphiles are added to the aqueous carbohydrate solutions (products 5–19), colloidal suspensions may form. It was shown in a study of fatty acid particle formation in water containing a surfactant [18] that the particle size of such suspensions depended on the chain length of the fatty acid. Gas bubbles have an affinity for lipophilic particulate surfaces providing stabilization of the gas phase [19–22], providing one possible mechanism for the observed bubble stabilizing effect during the dissolution of the carbohydrate-amphiphile admixtures. However, a more plausible mechanism is the formation of fatty acid Langmuir films at the gas–water interface, systems extensively described in the literature [17, 23–26]. If the amphiphilic compounds are spread on the gas–water interface, reduction of surface tension would result, as shown by isotherm studies in the cited literature. Reduced surface tension would increase bubble stability, explaining the observations in the present study. It is also well known from reports of investigation of aerosol systems that fatty acids with high log P tend to be organized at the gas–liquid as Langmuir films [17]. In that study, it was shown that chain length and the carboxylic acid functionality were important for the interfacial lifetime of the Langmuir films. One question arising is how the fatty acids with the highest log P and very limited solubility in water could achieve a dissolved state to form layers at the gas–water interface in the carbohydrate formulations. The ultrasonic influence in the present experiments may aid the dissolution process, as described in literature for systems comprising substances with low water-solubility [27].

Conclusion

In conclusion, the response parameters A 390, expressing the amount of gas-phase present during 390 s, and the bubble half-time t½ was shown to be useful main parameters in a screening method for increased persistence of the ultrasound contrast effect in vitro. Using these parameters, it was shown that the persistence and amount of released gas bubbles in formulations used in the commercial carbohydrate-based, gas-releasing available and improved ultrasound contrast agents (Echovist® and Levovist® respectively) could be improved more than 10 times using fatty acids with a higher log P relative to palmitic acid. Saturated fatty acids with chain length higher than 20 carbon atoms are commercially available, are found in many nutritional products and should find convenient use in pharmaceutical products. Specifically, the increases in A 390 and t½ shown for product 19b-c, and especially products 16a-b and 18b-c containing 5β-cholanic, behenic and melissic acid, respectively, are results that encourage further research and in vivo studies. Studies are ongoing to investigate the in vivo properties of the most promising test substances.

References

Goldberg BB (ed) (1997) Ultrasound contrast agents. Dunitz M Pub, London

Gramiak R, Shah PM (1968) Echocardiography of the aortic root. Invest Radiol 3:356–366

Klibanov AL (2002) Ultrasound contrast agents: development of the field and current status. Top Curr Chem, 222(Contrast Agents II):73–106

Eisenbrey JR, Burstein OM, Wheatley MA (2008) Effect of molecular weight and end capping on poly(lactic-co-glycolic acid) ultrasound contrast agents. Polym Eng Sci 48:1785–1792

Edey AJ et al (2008) Ultrasound imaging of liver metastases in the delayed parenchymal phase following administration of Sonazoid using a destructive mode technique (agent detection imaging). Clin Radiol 63:1112–1120

Tamasi F et al (2005) ECHOVIST-200 enhanced hystero-sonography: a new technique in the assessment of infertility. Eur J Obstet Gynecol Reprod Biol 121:186–190

Rasor JS, Tickner EG (1984) Microbubble precursors and methods for their production and use. US Patent 4,442,843

Uggowitzer MM et al (1999) Cerebral arteriovenous malformations: diagnostic value of echo-enhanced transcranial Doppler sonography compared with angiography. AJNR Am J Neuroradiol 20:101–106

Shiina Y et al (2009) Suitable solutions for reconstituting the ultrasound contrast agent “Levovist” used in contrast echocardiogram: in vitro and in vivo evaluation of the influence of osmotic pressure. Int J Cardiol 136:335–340

Nanda NC et al (2002) Multicenter evaluation of SonoVue for improved endocardial border delineation. Echocardiography 19:27–36

Regouw BJM et al (1971) Specific determination of free fatty acid in plasma. Clin Chim Acta 31:187–195

Davies JT, Rideal EK (1963) Interfacial Phenomena, 2nd ed. Academic Press, NY

Fritzsch T et al (1990) Sonographic contrast medium with fatty acid-containing microparticles and its preparation. Schering A.-G., Germany, p 7 (Application: DE)

Fritzsch T, Schartl M, Siegert J (1988) Preclinical and clinical results with an ultrasonic contrast agent. Invest Radiol 23(Suppl 1):S302–S305

Makyla K, Paluch M (2009) The linoleic acid influence on molecular interactions in the model of biological membrane. Colloids Surf B 71:59–66

Supardan MD et al (2006) Use of ultrasonic technique for measuring interfacial area in a two-dimensional bubble column. J Chem Eng Jpn 39:687–692

Gilman JB et al (2004) Selectivity and stability of organic films at the air-aqueous interface. J Colloid Interface Sci 280:234–243

Sherwin CP, Smith DE, Fulcher RG (1998) Effect of fatty acid type on dispersed phase particle size distributions in emulsion edible films. J Agric Food Chem 46:4534–4538

Goldenberg LC, Hutcheon I, Wardlaw N (1989) Experiments on transport of hydrophobic particles and gas bubbles in porous media. Transp Porous Media 4:129–145

Gonzenbach Urs T et al (2006) Stabilization of foams with inorganic colloidal particles. Langmuir 22:10983–10988

Ross VE (1997) Particle-bubble attachment in flotation froths. Miner Eng 10:695–706

Stechemesser H, Nguyen AV, Partzscht H (1998) Induction time in particle/gas bubble interaction. Theory and experiment. Freiberg Forschungsh A841 (Partikeltechnologie):177–190

Kundu S (2008) Langmuir-Blodgett film from a bimolecular layer at air-water interface. Colloids Surf A 317:618–624

Kundu S, Langevin D (2008) Fatty acid monolayer dissociation and collapse. Effect of pH and cations. Colloids Surf 25:81–85

Sakai K, Takagi K (1994) Observation of coexistence of gas and condensed phases in Langmuir films by scanning ripplon light scattering technique. Langmuir 10:802–806

Seok S et al (2009) Imaging of collapsed fatty acid films at air-water interfaces. Langmuir 25:9262–9269

Lee YH et al (2009) Effect of ultrasonic treatment on swine wastewater solubilization. Water Sci Technol 59:603–608

Acknowledgments

The authors wish to thank Nycomed Amersham ASA for help and support of the present work.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Hoff, L., Foss, P.A., Dyrstad, K. et al. Stabilization of Gas Bubbles Released from Water-Soluble Carbohydrates Using Amphiphilic Compounds: Preparation of Formulations and Acoustic Monitoring of Bubble Lifetime. J Surfact Deterg 14, 585–593 (2011). https://doi.org/10.1007/s11743-011-1250-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-011-1250-y