Abstract

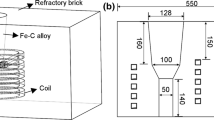

Based on a numerical analysis of the alternating electromagnetic field in the process of Steel refining with an induction ladle furnace (ILF), the optimization of the structure of ILF and the electromagnetic field for melting is realized in the present work. The optimization of the ILF by outward extension of inner yokes can decrease the magnitic flux leakage obviously, reduce the eddy current energy loss dramatically and then, decrease the total power consumption.

Similar content being viewed by others

References

So M., Development and operation of vacuum induction ladle furnace, Electric Steelmaking, 1993, 64: 290–295 (in Japanese)

Swaney R. U., Development of steelmaking technology for small sized special grades, Metall Plant and Tech. Intern., 1991, (5): 42–49

Deng K., Induction heating ladle furnace and its electrothermal characteristics, Iron and Steel, 1995, 30(Suppl.): 45–49 (in Chinese)

Deng K., Electromagnetic and structural characteristics of induction ladle furnace, J. Iron and Steel Res., 1997, 9(1): 5–8 (in Chinese)

Zhu S.J., Use FEM to calculate eddy-current field in induction ladle furnace, Industry Heating, 1994, (6): 3–7 (in Chinese)

Author information

Authors and Affiliations

Additional information

Project supported by the National Natural Science Foundation of China (5910427)

About this article

Cite this article

Deng, K., Shen, M., Ren, Z. et al. Improvement of the structure and the electromagnetic characteristics of an induction ladle furnace. J. of Shanghai Univ. 3, 153–156 (1999). https://doi.org/10.1007/s11741-999-0049-9

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11741-999-0049-9