Abstract

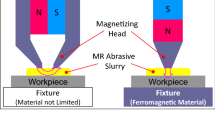

Magnetic abrasive finishing (MAF) can be used on CNC machine tools as a final machining step to finish workpieces after the milling process. This paper presents a new tool system for the magnetic abrasive finishing of flat surfaces on traditional CNC machine tools using permanent magnets and a paramagnetic adapter without magnetizing the spindle. Five MAF-tool types with variated dimensions, quantity and arrangement of the permanent magnets were developed and tested for machining ferromagnetic materials at different feed rate and equivalent cutting speed. The magnetic flux density was measured for all MAF-tool types with a Hall sensor and the distribution is presented graphically. The benefits of a novel top cover structure for MAF-tools are presented and 20 types of structures were tested as well as divided into three groups. Optimal top cover structures lead to a significant increase in the process capability and a surface roughness reduction for MAF of flat surfaces of ferromagnetic workpieces. Furthermore, the significant influence of the top cover material on the process capability was discovered and a total of seven metal and plastic materials were tested, which were milled from solid material or additively manufactured.

Similar content being viewed by others

References

Kala P, Pandey PM (2014) Experimental study on finishing forces in double disk magnetic abrasive finishing process while finishing paramagnetic workpiece. Procedia Mater Sci 5:1677–1684. https://doi.org/10.1016/j.mspro.2014.07.356

Kala P, Pandey PM (2015) Comparison of finishing characteristics of two paramagnetic materials using double disc magnetic abrasive finishing. J Manuf Process 17:63–77. https://doi.org/10.1016/j.jmapro.2014.07.007

Kala P, Pandey PM, Verma GC, Sharma V (2017) Understanding flexible abrasive brush behavior for double disk magnetic abrasive finishing based on force signature. J Manuf Process 28:442–448. https://doi.org/10.1016/j.jmapro.2017.04.010

Kanish TC, Kuppan P, Narayanan S, Denis Ashok S (2014) A Fuzzy Logic based Model to predict the improvement in surface roughness in Magnetic Field Assisted Abrasive Finishing. Procedia Eng 97:1948–1956. https://doi.org/10.1016/j.proeng.2014.12.349

Kanish TC, Narayanan S, Kuppan P, Denis AS (2017) Investigations on the finishing forces in Magnetic Field Assisted Abrasive Finishing of SS316L. Procedia Eng 174:611–620. https://doi.org/10.1016/j.proeng.2017.01.196

Kanish TC, Narayanan S, Kuppan P, Denis Ashok S (2019) Experimental Investigations on Magnetic Field Assisted Abrasive Finishing of SS 316L. Procedia Manuf 30:276–283. https://doi.org/10.1016/j.promfg.2019.02.040

Liu GY, Guo ZN, Jiang SZ, Qu NS, Li YB (2014) A study of processing Al 6061 with electrochemical magnetic abrasive finishing. Procedia CIRP 14:234–238. https://doi.org/10.1016/j.procir.2014.03.052

Mulik RS, Pandey PM (2011) Ultrasonic assisted magnetic abrasive finishing of hardened AISI 52100 steel using unbonded SiC abrasives. Int J Refract Hard Met 29:68–77. https://doi.org/10.1016/j.ijrmhm.2010.08.002

Naveen K, Vignesh SV, Balashanmugam N, Vinod P (2018) Ultra-precision finishing by Magnetic Abrasive Finishing process. Mater Today: Proc 5:12426–12436. https://doi.org/10.1016/j.matpr.2018.02.222

Sihag N, Kala P, Pandey PM (2015) Chemo Assisted Magnetic Abrasive Finishing: Experimental Investigations. Procedia CIRP 26:539–543. https://doi.org/10.1016/j.procir.2014.07.067

Sihag N, Kala P, Pandey PM (2017) Analysis of surface finish improvement during ultrasonic assisted Magnetic Abrasive Finishing on chemically treated Tungsten substrate. Procedia Manuf 10:136–146. https://doi.org/10.1016/j.promfg.2017.07.040

Sun X, Zou Y (2018) Study on electrolytic magnetic abrasive finishing for finishing stainless steel SUS304 Plane with a special compound machining tool. J Manuf Mater Process 41(2):231–242. https://doi.org/10.3390/jmmp2030041

Uddin MS, Santos V, Marian R (2019) Interplay of process variables in magnetic abrasive finishing of AISI 1018 steel using SiC and Al2O3 abrasives. J Manuf Mater Process 3:29–46. https://doi.org/10.3390/jmmp3020029

Wu PY, Yamaguchi H (2018) material removal mechanism of additively manufactured components finished using Magnetic Abrasive Finishing. Procedia Manuf 26:394–402. https://doi.org/10.1016/j.promfg.2018.07.047

Xing B, Zou Y (2020) Investigation of finishing aluminum alloy A5052 using the Magnetic Abrasive Finishing combined with electrolytic process. Machines 8:78–91. https://doi.org/10.3390/machines8040078

Yamaguchi H, Srivastava AK, Tan MA, Riveros RE, Hashimoto F (2012) Magnetic abrasive finishing of cutting tools for ma-chining of titanium alloys. CIRP Ann.–Manuf. Technol 61:311–314. https://doi.org/10.1016/j.cirp.2012.03.066

Yamaguchi H, Graziano AA (2014) Surface finishing of cobalt chromium alloy femoral knee components. CIRP Ann.–Manuf. Technol 63:309–312. https://doi.org/10.1016/j.cirp.2014.03.020

Yamaguchi H, Fergani O, Wu PY (2017) Modification using magnetic field-assisted finishing of the surface roughness and residual stress of additively manufactured components. CIRP Ann.–Manuf. Technol 66:305–308. https://doi.org/10.1016/j.cirp.2017.04.084

Zelinko A, Welzel F, Biermann D, Maiboroda V (2021) Influence of process parameters and initial surface on Magnetic Abrasive Finishing of flat surfaces on CNC machine tools. J Manuf Mater Process 5(4):108–122. https://doi.org/10.3390/jmmp5040108

Zou Y, Satou R, Yamazaki O, Xie H (2021) Development of a new finishing process combining a fixed abrasive polishing with Magnetic Abrasive Finishing process. Machines 9:81–94. https://doi.org/10.3390/machines9040081

Chang GW, Yan BH, Hsu RT (2002) Study on cylindrical magnetic abrasive finishing using unbonded magnetic abrasives. Int J Mach Tools Manuf 42:575–583. https://doi.org/10.1016/S0890-6955(01)00153-5

Judal KB, Yadava V, Pathak D (2013) Experimental investigation of vibration assisted cylindrical-magnetic abrasive finishing of aluminum workpiece. Mater Manuf Process 28:1196–1202. https://doi.org/10.1080/10426914.2013.811725

Song J, Shinmura T, Mun SD, Sun M (2020) Micro-machining characteristics in high-speed magnetic abrasive finishing for fine ceramic bar. Metals 10:464–476. https://doi.org/10.3390/met10040464

Kang J, Yamaguchi H (2012) Internal finishing of capillary tubes by magnetic abrasive finishing using a multiple pole-tip system. Precis Eng 36:510–516. https://doi.org/10.1016/j.precisioneng.2012.01.006

Kim JS, Chanchamnan S, Heng L, Kim G, Oh SH, Mun SD (2021) Development of an Inner Finishing Method for Brass Cone Pipe via a Movable Manual Electromagnet in a Magnetic Abrasive Finishing Process. Metals 11:1379–1388. https://doi.org/10.3390/met11091379

Nteziyaremye V, Wang Y, Li W, Shih A, Yamaguchi H (2014) Surface finishing of needles for high-performance biopsy. Procedia CIRP 14:48–53. https://doi.org/10.1016/j.procir.2014.03.010

Yamaguchi H, Kang J, Hashimoto F (2011) Metastable austenitic stainless steel tool for magnetic abrasive finishing. CIRP Ann.–Manuf. Technol 60:339–342. https://doi.org/10.1016/j.cirp.2011.03.119

Yamaguchi H, Nteziyaremye V, Stein M, Li W (2015) Hybrid tool with both fixed-abrasive and loose-abrasive phases. CIRP Ann.–Manuf. Technol 64:337–340. https://doi.org/10.1016/j.cirp.2015.04.006

Li W, Chen Y, Cheng M, Lv Y (2020) Effect of magnetic head shape on processing of titanium alloy wire by magnetic abra-sive finishing. Materials 13:1401–1410. https://doi.org/10.3390/ma13061401

Nam SS, Kim JS, Mun SD (2020) Magnetic Abrasive Finishing of beta-titanium wire using multiple transfer movement method. Appl Sci 10:6729–6741. https://doi.org/10.3390/app10196729

Hung CL, Ku WL, Yang LD (2010) Prediction system of Magnetic Abrasive Finishing (MAF) on the internal surface of a cylindrical tube. Mater Manuf Process 25:1404–1412. https://doi.org/10.1109/ICCIE.2010.5668401

Vahdati M, Rasouli SA (2016) Evaluation of parameters affecting Magnetic Abrasive Finishing on concave freeform surface of Al alloy via RSM method. Adv Mater Sci Eng. https://doi.org/10.1155/2016/5256347

Karpuschewski B, Byelyayev O, Maiboroda VS (2009) Magneto-abrasive machining for the mechanical preparation of high-speed steel twist drills. CIRP Ann.–Manuf. Technol 58:295–298. https://doi.org/10.1016/j.cirp.2009.03.046

Yamaguchi H, Srivastava AK, Tan MA, Hashimoto F (2014) Magnetic Abrasive Finishing of cutting tools for high-speed machining of titanium alloys. CIRP J Manuf Sci Technol 7:299–304. https://doi.org/10.1016/j.cirpj.2014.08.002

Acknowledgements

This work was supported by the Federal Ministry for Economic Affairs and Energy (ZIM)-ZF4045612TV9 on the basis of a decision by the German Bundestag.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declares no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zelinko, A., Welzel, F., Biermann, D. et al. Tool type and macrostructure for magnetic abrasive finishing of flat surfaces on CNC machine tools. Prod. Eng. Res. Devel. 16, 523–533 (2022). https://doi.org/10.1007/s11740-021-01097-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-021-01097-5