Abstract

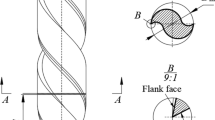

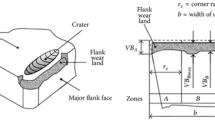

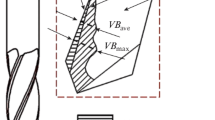

Product quality in machined parts is governed by many factors, out of which the state of wear of the tool is one of the most critical factors. Knowing the condition of the tool wear makes it possible to optimize the tool life and simultaneously maintain the surface quality. There are methods of online wear measurement proposed in the literature, like correlating some physical parameters to the wear state of the tool. As the processes are indirect, they do not provide exact values of the tool wear, but only aids in classifying the wear into different states from mild to severe. This work is focused on developing direct tool wear measurement by applying image processing techniques, which is more accurate, and precise. It has a very negligible interruption in production, and helps in automation of the task of tool wear monitoring and replacing it. In this paper, a novel online tool wear measuring algorithm is proposed using combined techniques of edge detection and segmentation. A complementary metal–oxide–semiconductor (CMOS) sensor camera is utilized to capture the wear zone images. The tool’s wear value is extracted by establishing wear boundaries through image processing, threshold segmentation, edge detection, and morphological operation. The machining tests are performed on a CNC lathe. The tool wear measured by the proposed technique is compared with the measurements obtained by an optical microscope. The results demonstrated high detection accuracy of the proposed approach enabling online tool wear monitoring during the turning process.

Similar content being viewed by others

References

Karandikar JM, Abbas AE, Schmitz TL (2014) Tool life prediction using Bayesian updating. Part 2: turning tool life using a Markov Chain Monte Carlo approach. Precis Eng 38(1):18–27

Stephenson DA, Agapiou JS (2016) Metal cutting theory and practice, 3rd edn. CRC Press. https://doi.org/10.1201/9781315373119

Lins RG, de Araujo PRM, Corazzim M (2020) In-process machine vision monitoring of tool wear for Cyber-Physical Production Systems. Robot Comput Integr Manuf 61:101859

Liang, S., & Shih, A. J. (2015). Analysis of machining and machine tools. Springer.

Zhou Y, Xue W (2018) Review of tool condition monitoring methods in milling processes. Int J Adv Manuf Technol 96(5–8):2509–2523

Dutta S, Pal SK, Mukhopadhyay S, Sen R (2013) Application of digital image processing in tool condition monitoring: a review. CIRP J Manuf Sci Technol 6(3):212–232

Byrne G, Dornfeld D, Inasaki I, Ketteler G, König W, Teti R (1995) Tool condition monitoring (TCM)—the status of research and industrial application. CIRP Ann 44(2):541–567

Liang SY, Hecker RL, Landers RG (2004) Machining process monitoring and control: the state-of-the-art. J Manuf Sci Eng 126(2):297–310

Teti R, Jemielniak K, O’Donnell G, Dornfeld D (2010) Advanced monitoring of machining operations. CIRP Ann 59(2):717–739

D’Addona D, Segreto T, Simeone A, Teti R (2011) ANN tool wear modeling in the machining of nickel superalloy industrial products. CIRP J Manuf Sci Tech 4(1):33–37

Segreto T, Simeone A, Teti R (2013) Multiple sensor monitoring n nickel alloy turning for tool wear assessment via sensor fusion. Proc CIRP 12:85–90

Segreto T, Caggiano A, Karam S, Teti R (2017) Vibration sensor monitoring of nickel-titanium alloy turning for machinability evaluation. Sensors 17(12):2885

Segreto T, D’Addona D, Teti R (2020) Tool wear estimation in turning of Inconel 718 based on wavelet sensor signal analysis and machine learning paradigms. Prod Eng Res Devel 14(5):693–705

Ong P, Lee WK, Lau RJH (2019) Tool condition monitoring in CNC end milling using wavelet neural network based on machine vision. Int J Adv Manuf Technol 104(1–4):1369–1379

Castejón M, Alegre E, Barreiro J, Hernández LK (2007) On-line tool wear monitoring using geometric descriptors from digital images. Int J Mach Tools Manuf 47(12–13):1847–1853

Saeidi O, Torabi SR, Ataei M (2013) Development of a new index to assess the rock mass drillability. Geotech Geol Eng 31(5):1477–1495

Zhang C, Zhang J (2013) On-line tool wear measurement for ball-end milling cutter based on machine vision. Comput Ind 64(6):708–719

D’Addona DM, Teti R (2013) Image data processing via neural networks for tool wear prediction. Procedia CIRP 12:252–257

Pfeifer T, Wiegers L (2000) Reliable tool wear monitoring by optimized image and illumination control in machine vision. Measurement 28(3):209–218

Kim JH, Moon DK, Lee DW, Kim JS, Kang MC, Kim KH (2002) Tool wear measuring technique on the machine using CCD and exclusive jig. J Mater Process Technol 130:668–674

Sortino M (2003) Application of statistical filtering for optical detection of tool wear. Int J Mach Tools Manuf 43(5):493–497.

Obikawa T, Shinozuka J (2004) Monitoring of flank wear of coated tools in high speed machining with a neural network ART2. Int J Mach Tools Manuf 44(12–13):1311–1318

Liang, Y. T., Chiou, Y. C., & Louh, C. J. (2005). Automatic wear measurement of Ti-based coatings milling via image registration. In MVA (pp. 88–91).

Jurkovic J, Korosec M, Kopac J (2005) New approach in tool wear measuring technique using CCD vision system. Int J Mach Tools Manuf 45(9):1023–1030

Xiong, G., Liu, J., & Avila, A. (2011, August). Cutting tool wear measurement by using active contour model based image processing. In 2011 IEEE International Conference on Mechatronics and Automation (pp. 670–675). IEEE.

Wang WH, Hong GS, Wong YS (2006) Flank wear measurement by a threshold independent method with sub-pixel accuracy. Int J Mach Tools Manuf 46(2):199–207

Su JC, Huang CK, Tarng YS (2006) An automated flank wear measurement of microdrills using machine vision. J Mater Process Technol 180(1–3):328–335

Wang W, Wong YS, Hong GS (2005) Flank wear measurement by successive image analysis. Comput Ind 56(8–9):816–830

Kurada S, Bradley C (1997) A machine vision system for tool wear assessment. Tribol Int 30(4):295–304

Kene AP, Choudhury SK (2019) Analytical modeling of tool health monitoring system using multiple sensor data fusion approach in hard machining. Measurement 145:118–129

Dutta S, Pal SK, Sen R (2016) On-machine tool prediction of flank wear from machined surface images using texture analyses and support vector regression. Precis Eng 43:34–42

Hou Q, Sun J, Huang P (2019) A novel algorithm for tool wear online inspection based on machine vision. Int J Adv Manuf Technol 101(9–12):2415–2423

D’Addona DM, Matarazzo D, Ullah AS, Teti R (2015) Tool wear control through cognitive paradigms. Procedia CIRP 33:221–226

Astakhov VP (2011) Turning., Chapter 1 in book “MODERN MACHINING TECHNOLOGY: A practical guide”. In: Davim JP (eds) WOODHEAD/CHANDOS Oxford (UK), pp 1–78

Astakhov VP (2004) The assessment of cutting tool wear. Int J Mach Tools Manuf 44(6):637–647

Moldovan OG, Dzitac S, Moga I, Vesselenyi T, Dzitac I (2017) Tool-wear analysis using image processing of the tool flank. Symmetry 9(12):296

Wayalun, P., Chomphuwiset, P., Laopracha, N., & Wanchanthuek, P. (2012, August). Images Enhancement of G-band Chromosome Using histogram equalization, OTSU thresholding, morphological dilation and flood fill techniques. In 2012 8th International Conference on Computing and Networking Technology (INC, ICCIS and ICMIC) (pp. 163–168). IEEE.

Funding

The work was supported by Nirma University in the form of the Minor Research Project Grant with letter number “NU/DRI/MinResPrj/IT/21-22”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bagga, P.J., Makhesana, M.A. & Patel, K.M. A novel approach of combined edge detection and segmentation for tool wear measurement in machining. Prod. Eng. Res. Devel. 15, 519–533 (2021). https://doi.org/10.1007/s11740-021-01035-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-021-01035-5